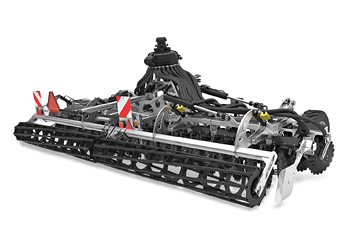

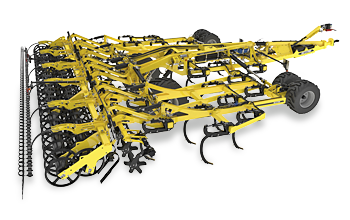

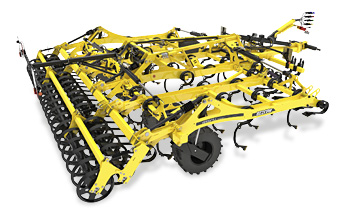

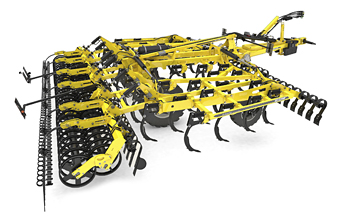

SEEDBED PREPARATION USING A SEEDBED CULTIVATOR

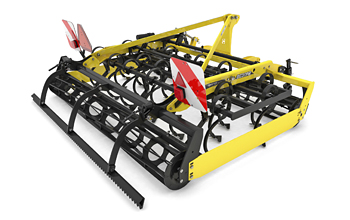

In addition to standard straw harrows and levellers, seedbed cultivators are the most frequently used implements in seedbed soil cultivation after tillage. The SWIFTER seedbed cultivators are able to combine up to eight operations to create a quality seedbed for crop establishment during a single pass. It is important to minimise travelling across the field, especially during the spring cultivation, in order to maintain winter moisture in soil and eliminate its evaporation.

By combining several operations into a single pass, you can not only prepare a quality seedbed, but also reduce the costs of seedbed preparation. The Crushbar levelling bar or a mechanic leveller break the rough furrow well and level the surface; the shank or gamma tip section create a loosened soil structure, and the efficient combination of rollers provide the perfect soil structure with final surface consolidation, which is prevented from evaporation.

“We have become the most important global supplier of technology with a working width from 10′ to 60′ in this implement category thanks to the long-term development and testing.”

SWIFTER Seedbed Cultivators

![<![CDATA[Řezy půdy_Rubberpacker]]><![CDATA[Řezy půdy_Rubberpacker]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_rubber_pack.png)

BEDNAR FMT

BEDNAR FMT

![<![CDATA[Řezy půdy_Trubkový pěch]]><![CDATA[Řezy půdy_Trubkový pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_trubkovy_valec.png)

![<![CDATA[Řezy půdy_Trubkový pěch]]><![CDATA[Řezy půdy_Trubkový pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_spring_pech.png)

![<![CDATA[Řezy půdy_Segmentový pěch]]><![CDATA[Řezy půdy_Segmentový pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_segmentovy_valec.png)

![<![CDATA[Řezy půdy_Dvouválcový pěch]]><![CDATA[Řezy půdy_Dvouválcový pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_dvouvalcovy_pech.png)

![<![CDATA[Řezy půdy_U-Ring pěch]]><![CDATA[Řezy půdy_U-Ring pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_u-ring.png)

![<![CDATA[Řezy půdy_V-Ring pěch]]><![CDATA[Řezy půdy_V-Ring pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_v-ring.png)

![<![CDATA[Řezy půdy_Cutpack pěch]]><![CDATA[Řezy půdy_Cutpack pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_cutpack.png)

![<![CDATA[Řezy půdy_Presspack pěch]]><![CDATA[Řezy půdy_Presspack pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/pechy_valce_double_presspack.png)