Double front swivel gauge wheels

Help maintain the set working depth, follow the ground’s contour and make headland turns.

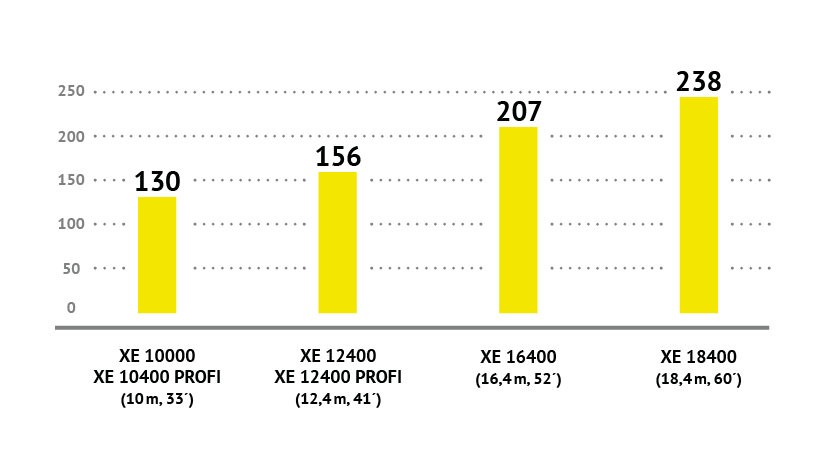

The SWIFTERDISC XE_PROFI large-working-width high-speed disc harrow designed for maximum performance has a compact frame and easy intuitive control. Two models available in 34 and 41 feet intended for working speeds of up to 11 mph enable achieving high work rates, and thus bring cost savings and high daily outputs.

1-5.5 in

34.1-40,7 ft

350-620 hp

SWIFTERDISC XE_PROFI disc harrows with intuitive control and a range of technical advantages to enhance work quality.

Stubble management is one of the most important farming procedures. According to the proper agricultural practices it should be done as soon after harvest as possible. For this operation the SWIFTERDISC XE_PROFI can be equipped with notched or aggressive disc blades with 20.5- or 22-inch diameter providing excellent penetration, cutting, mixing of soil and incorporation of crop residue. Rear rollers reconsolidate the tilled soil profile to ensure even emergence and germination of weeds and volunteer grains.

The optimal diameter in combination with the high working speed provide a high circumferential velocity of the blades that guarantees an excellent crumbling and mixing effect of the disc section. The leveler in front of the rear packers helps with the final surface levelling together with the excellent crumbling effect of the packers resulting in a perfectly level field.

SWIFTERDISC XE_PROFI is fully compatible with ISOBUS and the machine can be operated with any ISOBUS compatible terminal. The BEDNAR EASY CONTROL software provides a fully automated folding and unfolding of the machine with the push of a single button and all working parameters are set by entering the desired values on the terminal. All settings including working depth can also be conveniently adjusted on the fly, avoiding unnecessary downtimes.

SWIFTERDISC XE_PROFI has disc sections arranged symmetrically in the shape of the letter X. This innovative design eliminates machine’s side drifting, which enables the implement to precisely follow the tractor. The middle disc eliminates the risk of ridge formation.

Maintaining the set working depth for even soil profile processing is the foundation of quality tillage. The SWIFTERDISC XE_PROFI disc harrows apply the same downpressure on all discs across the entire machine width thanks to the transport axle position and the concept of two folding side frames. This arrangement of the machine lowers the number of hydraulic cylinders where the wing frame downpressure could drop. This design also reduces the number of necessary lubrication points, the overall wear of the machine and improves machine’s agility, both in the field and on the road.

Even with working width of 41 feet SWIFTERDISC XE_PROFI is very compact in transport mode as it doesn’t exceed 10-foot transport width and the transport height stays just below 13 feet. This is achieved by forward folding of the wings toward the tongue.

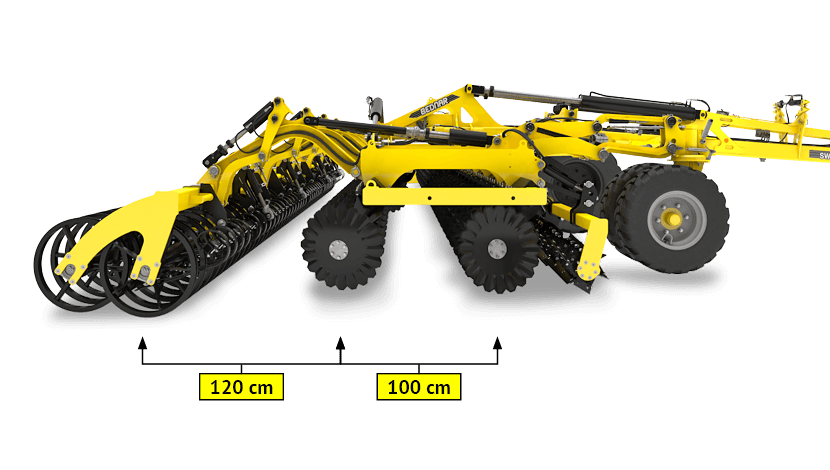

Machines can often clog up when discing stubble or incorporating large amounts of crop residue due to low clearance or when the working speed is limited to avoid a washboard effect. In its segment, the SWIFTERDISC XE_PROFI offers the largest distance between the two gangs of blades, 39 inches, and the space between the disc section and the rear rollers is up to 47 inches. The frame clearance of 23.5 inches enables work in heavy residue or manure incorporation.

The SWIFTERDISC XE_PROFI disc harrow can be equipped with the ALFA DRILL air seeder unit straight from the factory for seeding of cover crops and small grains in a single pass with considerable time and fuel saving benefits. The seeding unit hopper has a capacity of 23 bushels.

The CTF (controlled traffic farming) system eliminates soil compaction and optimizes traffic of equipment setups. While working, each setup travels across the field in particular tramlines of a given grid with a span according to the equipment working width (20, 40, 60, 80 feet, etc.) which limits soil compaction only to permanent wheel tracks that could be easily deep tilled.

SWIFTERDISC XE_PROFI can be maneuvered on headlands with ease. It makes headlands turns off the rear rollers and front gauge wheels with just the disc section lifted without the need of lifting the entire frame. This design eliminates the negative load on the hitch and unweighting of the tractor rear during a headland turn.

The SWIFTERDISC XE_PROFI disc connects to tractor’s Load Sensing hydraulics via three lines. The adjustable load sense pump delivers only as much oil and under such pressure as demanded by the specific task of the individual implement function, all done completely automatically. The system efficiently uses pressure in the hydraulic system to control individual functions requiring high output.

The large-working-width SWIFTERDISC harrows are designed for connection with the most powerful tractors on the market. They offer maximum performance and daily outputs thanks to sophisticated design and high working speed.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the high-performance disc harrow

Cuts crop residue, namely sunflower, corn or rapeseed stalks to make for easier incorporation and mixing with soil and to accelerate its breakdown.

Provides ideal weight distribution of the implement and contributes to precise maintenance of the set working depth thanks to even disc section downpressure.

Provide excellent terrain contouring and maintain the set working depth across the entire working width. The disc travels on the swivel gauge wheels and the rear rollers also during headland turns.

Notched or aggressive discs available in 20.5- or 22-inch diameter with 0.2-inch thickness deliver high throughput thanks to the TWIN-DISC system.

Ensures safe turning on headlands and enables forward folding of the wings.

The wide range of rear packers make it possible to adjust the machine to any conditions. The packers help close the surface and reduce evaporation of soil moisture.

“The rented machine convinced us by job quality in all conditions. The harrow is capable of maintaining the set working depth in dry conditions thanks to its weight and disc geometry and incorporate crop residue well. Another reason to purchase the machine from BEDNAR was our requirement for 22” disc, crossbar leveler and rear U-RING packer for soil reconsolidation. All requirements were met by BEDNAR. On top of all that, we required an air seeder unit for cover crop seeding. In this category BEDNAR also offers a factory solution none of the competition can provide.

Vaclav Liska, service manager

Janovsky Agro, Tyn nad Vltavou (Czechia)

We know that every farmer has different requirements for optional machine equipment and its intended use. That’s why we let you specify your own SWIFTERDISC XE_PROFI to exactly match your needs.