Tube roller

The screw-shaped cage packer formed by rods crumbles the clods on the field surface.

The low towing demands make the SWIFTER SN mounted seedbed cultivator suitable for aggregation with lower power tractors, which are often used by smaller farmers. The working width of these cultivators ranges from 9.8 to 16.4 feet. The effective combination of working parts provides intense levelling, mixing, clod crumbling and final field surface levelling. In one pass, you can prepare the perfect seedbed and thus achieve savings in the total costs.

1-5 in

10-16.5 ft

90-200 hp

A mounted seedbed cultivator suitable for traditional soil cultivation before seeding.

Combining several operations into one means fewer passes through the field and lower costs of soil preparation. The front levelling bar perfectly levels any unevenness. The front roller crumbles the clods. The main working section undercuts, aerates and warms up the soil layer. The final clod crumbling is provided by various types of rollers in combination with other equipment behind the rollers.

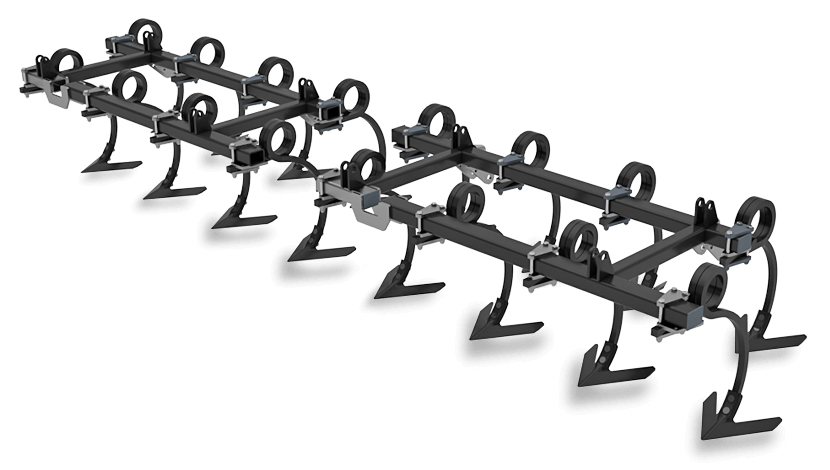

A sweep working section (summer and autumn soil cultivation – winter cereals, oilseed rape)

This working section can be used for summer and autumn preparation when soil needs to be loosened, undercut and mixed after the previous harvest. The 10.6 inches sweeps in two overlapping rows undercut the soil profile along the entire machine width, creating a firm bottom. At the same time, soil is aggressively processed thanks to the working angle of the sweeps, creating a loosening top layer. Each sweep is mounted on a flexible tine that provides a 3D effect (horizontal and vertical movement) which protects the sweep from damage.

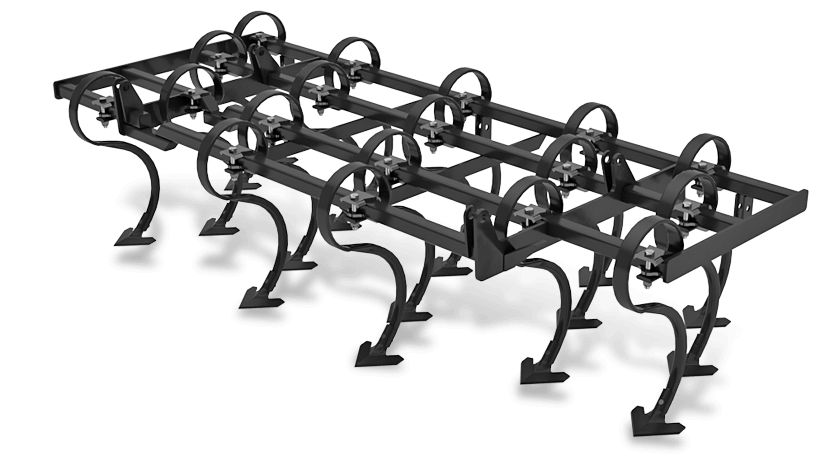

SB sweep section with spring sweeps (spring soil cultivation – sugar beet)

The section is especially suitable for spring cultivation before seeding sugar beet where it is required to adequately manage spring moisture, but still prepare a precise seedbed. The sweep angle does not mix soil vertically, but the soil is still undercut in the whole area thanks to the overlapping sweeps that are 170 mm wide. Another benefit is the reduced demand on the towing vehicle power.

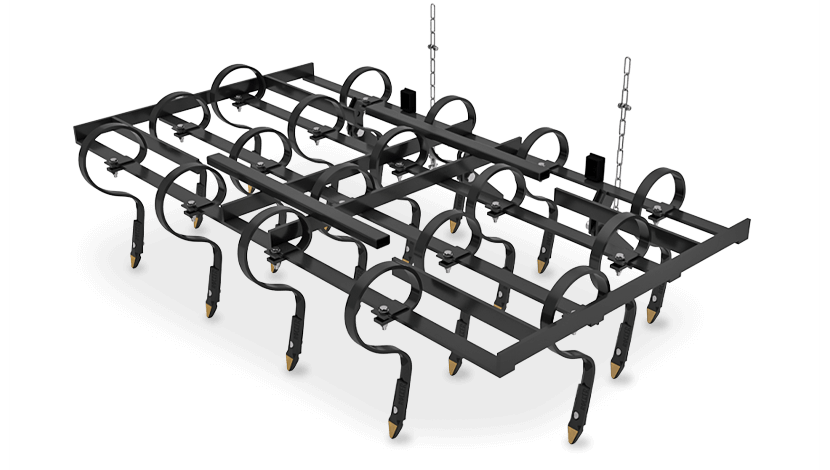

Gamma-point working section (spring soil cultivation – spring cereals, corn)

This section is suitable for early spring operations, such as required before seeding barley. The four rows of gamma points at a negative angle aerate and warm up soil without bringing wet particles to the surface, which preserves winter moisture. It is important for a fast start of the growth of spring crop. The spring-loading of each tine enables working at high speed. The gamma points for this section are also available in the LONG LIFE version.

Even the smallest models of the SWIFTER SN mounted seedbed cultivators are easily controllable. You can choose from mechanical regulation of the working depth, or comfortable hydraulic regulation.

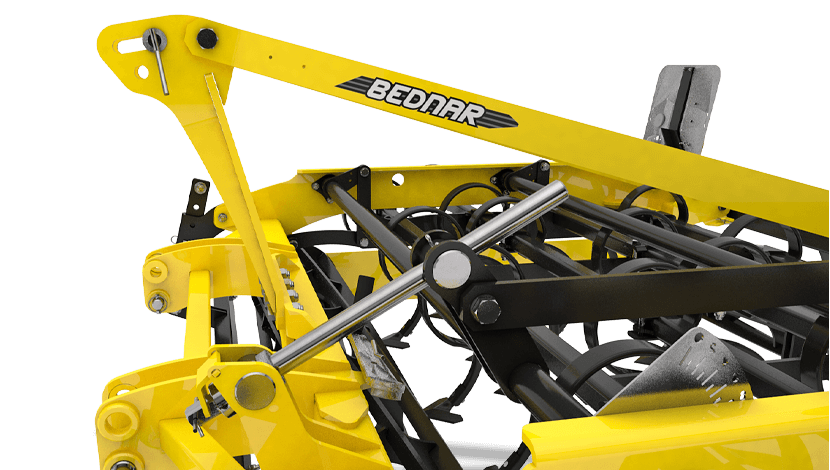

The width of the machine is a limiting factor for transportation on roads in the European Union. Therefore, the SWIFTER SN 4000 and 5000 are manufactured in the folding version to ensure safe transport. The centre of gravity of the cultivator is moved as close to the tractor hitch as possible, so the set is stable even at high transport speed.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the seedbed cultivator.

Easy aggregation to the tractor three-point hitch, category II or III.

The mechanically controlled front levelling bar is used for levelling unevenness and breaking the rough furrow.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 rows of sweeps/ 4 rows of gamma points / 2 rows of SB sweeps) as needed for soil cultivation for the crop.

The single-row crosskill roller contributes to perfect crumbling of clods created by the sweep or gamma-point section.

The finish roller creates the final fine soil structure.

Easy aggregation to the tractor three-point hitch, category II or III.

The mechanically controlled front levelling bar is used for levelling unevenness and breaking the rough furrow.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 rows of sweeps/ 4 rows of gamma points / 2 rows of SB sweeps) as needed for soil cultivation for the crop.

The folding version of the machine is additionally equipped with hydraulic cylinders.

The single-row crosskill roller contributes to perfect crumbling of clods created by the sweep or gamma-point section.

The finish roller creates the final fine soil structure.

“To be able to influence the yield of the grown crops as early as during the first soil cultivation, we have to use quality machines that make it possible. Therefore, I decided to purchase the SWIFTER SN seedbed cultivator so that I can prepare a quality seedbed in one pass. Yes, someone might object that I only need a simple and cheap harrow for 45 hectares, but every good farmer knows that a quality seedbed is essential for good seed emergence, and I am also aware of that, that is why I chose BEDNAR.”

Karel Řehoř,

a private farmer, Farma na Rychtě, Gruna (district of Svitavy, CZ)

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTER SN seedbed cultivator to precisely match your needs.