Hydraulic protection

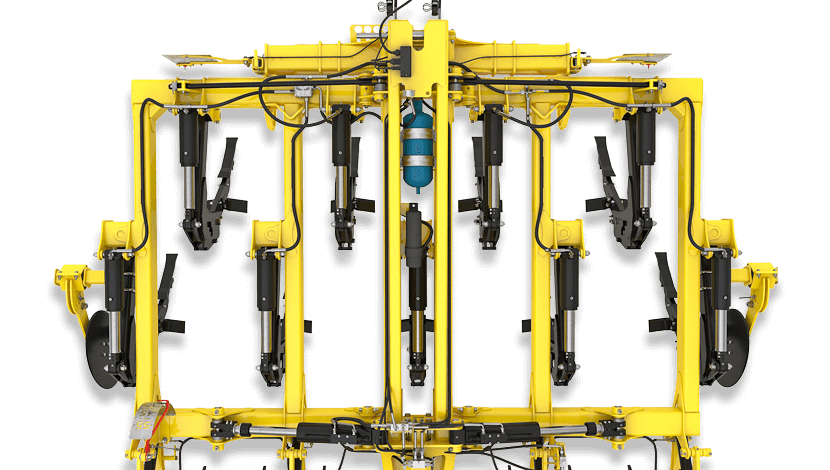

Comfortable hydraulic AUTO-RESET shank protection for rocky and extremely hardened soils. The release force of each shank starts at 2205 lb and ends at 3307 lb.

![<![CDATA[Hydraulické jištění]]><![CDATA[Hydraulické jištění]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/tn_hd7r_00134927_pkv_zero_mix_hydraulicke_jisteni.png)

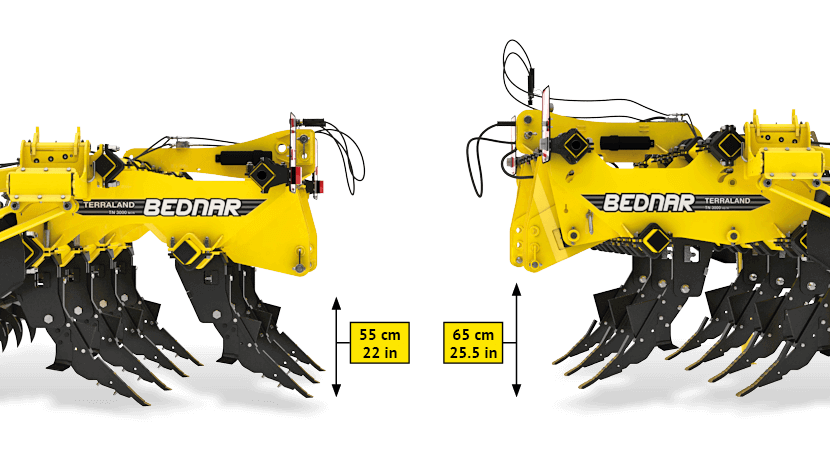

The TERRALAND TN mounted ripper is a tool for deep tillage up to a depth of 25.5″. What makes this implement a success is the fact that it can replace traditional tillage, and when compared with a plough, it works deeper, faster and with lower demands on the tractor power. The TERRALAND TN ripper is manufactured with two working width options of 9′ 10″ ft and 13′ 1″. The properties of TERRALAND TN make it suitable for deep loosening and incorporation of large quantities of organic matter.

22" -25.5" in

9' 10" -13' 1" ft

150-350 hp

TERRALAND TN ripper deep loosening, including the option of replacing shanks and rollers. Active-mix shanks for deep loosening. Zero-Mix shanks just for subsoiling without mixing the soil.

TERRALAND TN is manufactured in two versions, TN_D with a maximum working depth of 25.5″, and TN_M with a maximum working depth of 22″. The shank protection in both versions is either mechanical using shear bolts, or hydraulic reset shank protection.

The mounted TERRALAND TN 13′ HD9 ripper is equipped with 9 shanks with a spacing of 17.7″.The individual shanks are fitted with hydraulic reset protection. The TERRALAND TN 13′ HD9 ripper has a transport width of 9′ 10″ to ensure trouble-free transport on roads. The TN 13′ HD9 ripper can be also equipped with the rear V-RING packer.

The TERRALAND TN ripper in combination with Active-Mix shanks and spiked rollers is suitable for deep loosening. The special shape of the shanks provides easy soil penetration, and excellent loosening and mixing effect. In one pass, the soil profile is loosened in depth and the soil surface is intensely mixed and levelled.

The TERRALAND TN frame can be equipped with special Zero-Mix shanks, with a negative angle, and the heavy steel Cutpack for subsoiling without active mixing of soil. This operation is suitable for disrupting hardened soil layers, aerating the soil profile, and creating a proper soil environment.

The individual parts of the TERRALAND TN ripper are assembled, not welded. The assembled parts (shanks to frames, internal frames to shank beams) have a multiple-times longer service life than when those exposed parts are welded together.

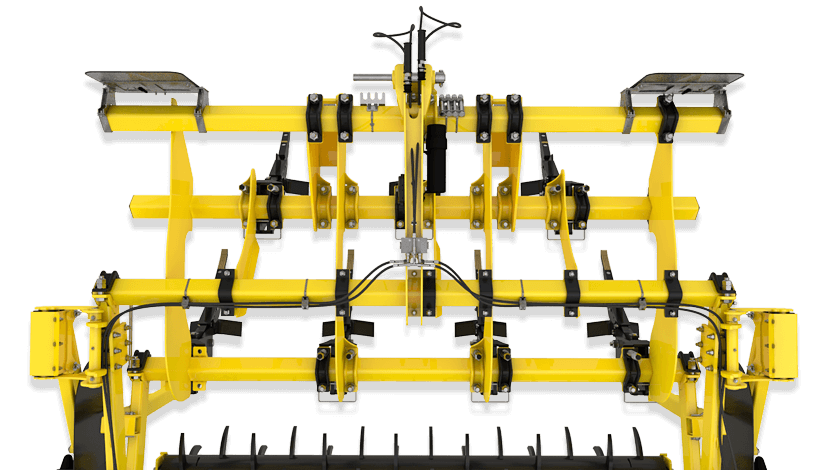

The TERRALAND TN ripper consists of two ranks of shanks, followed by tandem spiked rollers. Active shanks provide deep soil loosening, tandem spiked rollers overlap and offer an excellent crumbling effect. The advantage of the rollers is that they can be adjusted according to the required work, for example, in rocky soils.

The TERRALAND TN 10′ implement frame can be equipped with five or seven shanks. The spacing of shanks when five are used is 24″. When seven shanks are used on the TERRALAND TN frame, the spacing is 15.7″. This design offers even better loosening and mixing of soil profile.

The TERRALAND TN 13′ ripper frame can be equipped with seven or nine shanks. The spacing of shanks when seven are used is 22.2″. The model with nine shanks offers spacing of 16.7″.

ACTIVE-MIX shanks can be equipped with points with a width of 2.8″ for intense loosening, or with a width of 1.6″ for demanding conditions and deep work. The shank wings undercut the disrupted bottom layer to eliminate clod formation. Points and wings are also available in the extremely durable LONG LIFE version (1.6″, 2.2″ and 2.8″). The deeper you work, the narrower the point should be.

The FERTI-BOX FB_F front mounted tank is primarily designed for supply fertilization directly in the soil profile and has a capacity of 54 – 62 bu. Fertilizer is pneumatically distributed from the front tank to the distribution tower mounted on the chisel plough.

The FERTI-CART FC is trailed cart which has a capacity of 100 bu. The orifice of the polyethylen tank has a large inclination that allows to apply lower-quality fertilizers. The TERRALAND TN chisel plough bar is easily connected using a three-point hitch.

The COMBO SYSTEM CS two tanks air-cart has a total capacity of 140 bu. The chisel plough is connected in the three-point hitch of the cart. The cart design enables applying two types of fertilizer in one pass, or use both tanks for one fertilizer.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working tools of the ripper

The shanks layout ensures excellent loosening effect and mixing of crop residue with soil up to a depth of 25.5″. Two types of shanks are available for deep loosening or subsoiling.

Each shank is individually protected, either hydraulically, or mechanically with the shear bolt

Maintain cultivated soil along the working width without the risk of side ridge formation.

The additional side spiked rollers perfectly level any potential ridges created on the sides of the implement.

Rear tandem rollers with a diameter of 10″ have overlapping spikes that provide excellent self-cleaning effect.

“We had the opportunity to test the TERRALAND TN first, we had a choice of rippers from five different manufacturers. The quality of work convinced us, as well as the references from the neighbouring companies that use TERRALAND TN, for instance, to process soil for potatoes. The ripper works great. Right now, we are using shanks equipped with LONG LIFE carbide points, since they have a longer service life than the standard version. They are definitely a better solution for our rocky soils.”

Michal Vanek, Chief Agronomist,

VOD Kamen (Czech Republic)

We know that everyone has different requirements for the optional implement equipment and its expected use. Therefore, you can specify your own TERRALAND TN to precisely match your needs.