March

2021

Jan Bednář Introduces the COMBO-SYSTEM CS…

Check out the video introduction of a set consisting of the COMBO-SYSTEM CS 5000 storage tank and the CORSA CN 9000 seeding bar.…

The COMBO SYSTEM CS trailed storage tank is designed for aggregation with mounted soil cultivators and seed drills. The double-chamber tank offers a total capacity of 142 bu in the ratio of 60:40. The pressurised tank increases the accuracy of batching and enables to also apply large amounts of fertiliser or seeds.

142-142 bu

A universal storage tank for precise seeding amounts or fertiliser application in aggregation with mounted equipment.

The COMBO SYSTEM CS trailed storage tank can be used all year round. The three-point hitch makes it possible to aggregate the trailed storage tank with various machines – it can be used for seeding cereals and oilseed plants in combination with the CORSA CN seeding bar.

The trailed storage tank can be aggregated with various machines thanks to a three-point hitch or a towing lug – it can be used in combination with the TERRALAND TN chisel plough, or TERRASTRIP ZN and STRIP-MASTER EN.

A great advantage of the COMBO SYSTEM CS trailed storage tank is the two chambers. In one pass, you can apply fertiliser and plant seeds at the same time, or you can use both chambers for seeds or fertiliser depending on the field operation. The individual types of seeds/fertiliser can be mixed in the pipes. The large hopper capacity allows working without the need for frequent refills.

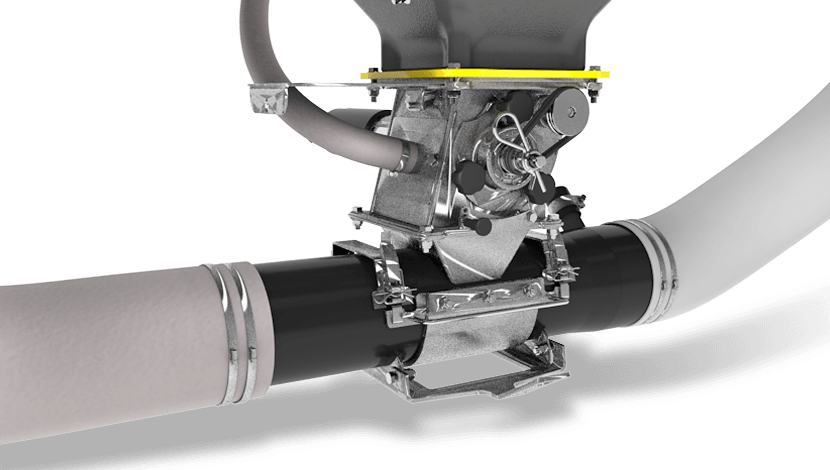

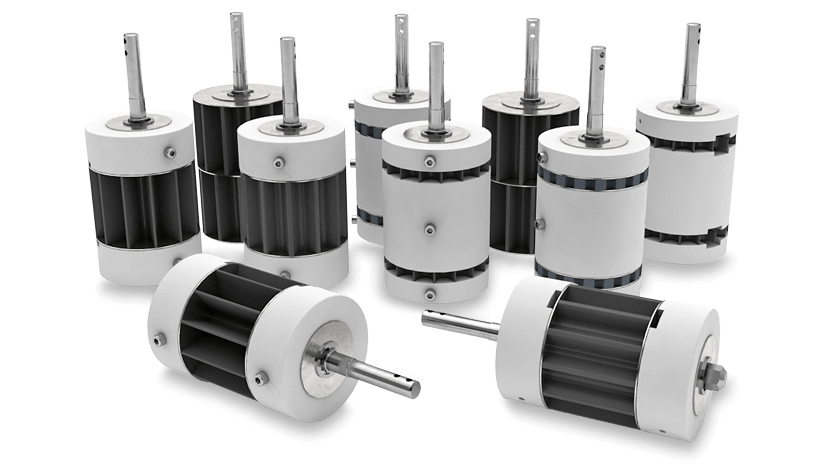

The individual chambers of COMBO SYSTEM CS are equipped with their own dispensing mechanisms. The stainless dispensing mechanisms with electric drives enable changing the application amounts independently for both chambers, as required by the agronomist.

The dispensing mechanism is made of stainless steel and driven by an electric motor, as a result of this the dispensed amount is precise at any speed. It is equipped with a GPS speed sensor.

Our portfolio includes various types of seeding rollers for the application of different fertiliser and seed sizes. We offer seeding rollers from 30 cm³ to 790 cm³.

Overpressure is created in the hopper thanks to the airtight closure. This technical solution increases the quality of fertiliser batching precision, even in case of higher application amounts.

Setting the batches and hopper control is very easy. The FERTI-BOX FB mounted hopper can be controlled using ISOBUS on the tractor display, or using BEDNAR terminals, starting with the ME TOUCH SMART 570 terminal to ME TOUCH 800 with a touch display and a diagonal measurement of 8″.

The COMBO-SYSTEM CS double-chamber trailed hopper can be equipped with a camera system that provides an overview of the aggregated equipment. A camera can also be placed inside the chambers. In relation to the equipment, the camera image is shown on the tractor display or BEDNAR terminal.

The COMBO SYSTEM CS storage tank is equipped with large floating tyres with a dimension of 650/65-30.5. The floating tyres have a low specific pressure on soil, they prevent potential soil compaction, which most often occurs when the set turns at headland, or works in wet conditions.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the trailed hopper.

Used for the connection of various types of mounted machines. The three-point hitch can be replaced for a towing lug for connecting trailed machines.

The transport axle is equipped with large floating tyres with a diameter of 650/65-30.5 that reduce pressure on soil and provide stability during transport.

Two stainless dispensing mechanisms with independent batch setting for high precision.

The double-chamber pressurised hopper with a total capacity of 142 bu provides precise batching of high amounts of seeds or fertiliser.

With weight of up to 3 307 lb, it adds extra weight to the rear axle of the tractor and improves its towing properties.

“We purchased the storage tank for fertilization into soil horizon at a depth of 15-20 cm below sugar beet. The supplementary fertilization will increase our yield.”

Ing. Václav Havlíček, Machinery Technician

Senice na Hané Farming Cooperative

You are one step closer to your new machine.

You can try all the equipment in our configurator,

or read about it in the brochure.

PROFILE FERTILISATION

The application of fertiliser into the soil environment known as profile fertilisation should be carried out together with depth loosening using FENIX cultivators, combined ACTROS cultivators or TERRALAND chisel ploughs. Such precisely placed fertiliser motivates the root system to grow faster and bigger which helps solve current issues with soil moisture. This fertiliser placement system is most often used for establishing deep-rooting crops such as corn, sugar beet or oilseed rape.

| COMBO SYSTEM CS | CS 5000 | |

|---|---|---|

| Transport width | ft | 10 |

| Transport length | ft | 18.7 |

| Transport height | ft | 10 |

| Reservoir volume | bu | 142 |

| Hopper chamber ratio | 60:40 | |

| Filling hole diameter | in | 23 x 31,1 / 23 x 60,2 |

| Number of batching devices | pcs | 2 |

| Filling height | ft | 1,2 |

| Rear hitch type | 3-point | |

| Maximum axle load | lb | 7 055 |

| Maximum hitch load | lb | 6 151 |

| Hitch type | lug 40, 51, 55, 62, 71, 73 | |

| Transport tyre dimensions | 650/65-30,5 | |

| Max. total weight* | lb | 13 206 |

*according to the machine equipment