MATADOR MO

6-6 m

280-400 hp

5000 l

Each crop requires specific conditions for its establishment, based on the selected soil cultivation technology and weather conditions. Generally, the crop should be established by the specified agronomic deadline to meet all the preconditions for achieving the required yield.

The advantage of the OMEGA seed drills lies in their high versatility that makes it possible to use these compact machines in zero tillage technologies with larger quantities of crop residue, or in traditional convention technology with the option to seed into rough furrow thanks to the efficient combination of the working parts or to establish catch crops, grass or crops directly in a stubble field. The same applies to the wide-working width EFECTA CE and EFECTA CM air seeders, which, however, do not have a disc section for soil cultivation like OMEGA but the EFECTA CE seed drill can be equipped with four types of front equipment.

BEDNAR Seed Drills

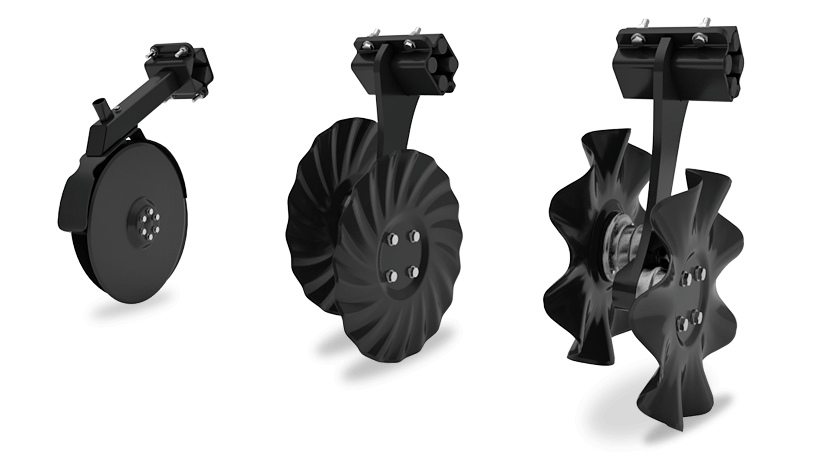

The OMEGA seed drills have a unique combination of working parts. The basic equipment of the machine includes a double-row working disc section, which may be retracted when they are not needed. The disc section is followed by the unique PROFI coulters section. This section helps deal with the problem soil clods, namely when seeding in heavy or wet soils when the disc section may form sticky clods. The specially shaped PROFI coulters crumble and help to level the soil efficiently. If seeding onto ploughing or cultivated soils, it is possible to mount the hydraulically adjustable levelling Crushbar in front of the cultivating disc section to help break down and level the surface.

In spring, the OMEGA seed drill can work with the discs completely retracted. The PROFI coulters manage the disc work, i.e., warming up, aerating the top soil profile. This results in a well-established crop with an excellent and uniform emergence in the whole field.

In summer, the intense work of the front discs is very important. The discs loosen soil, cut up any crop residue and mix it with soil. The PROFI coulters increase disc efficiency, i.e., they process the clods disc by disc, cut up and press the remaining crop residue into the ground.

Both the universal OMEGA and the wide EFECTA CE seed drills can be equipped with TURBO coulters, instead of the PROFI coulters. TURBO coulters work in the same line as the rear drill coulters. The sharp edge of the TURBO coulters creates a groove where the drill coulter places the seed. This equipment option is also suitable for seeding meadows and pastures.

The third equipment option includes the fertilising FERTI coulters, designed for the application of fertiliser into inter-rows and concurrent seeding in one pass. The seeding depth can be easily set. The fertiliser application into inter-rows helps to start the crop growth fast, more efficient use of fertiliser with easy access to seeds, and demonstrably higher yield.

OMEGA OO_FL Seed Drill with Supplementary Fertilisation

The main reasons for using intermediate crop in the seeding methods in the past few years lie in the legislation and ecology. The pressure on implementing better principles to limit soil and air erosion is increasing, as well as on improving the balance of organic matter, increasing water infiltration in soil, and reducing the application of chemicals. In the long term, intermediate crop can improve the condition of soil environment, increase the share of organic matter, and thus work better with the limiting factors of yield, such as moisture and nutrition of the main crop.

A catch crop is grown to improve soil conditions; it aerates the soil and creates organic green matter that continuously subsides. Catch crops perfectly aerate the soils. Each type of catch crop (tare grass, phacelia, buckwheat, niger, scarlet clover, Indian millet, flax, mustard) has a different task because the roots of each catch crop reach a different depth. The roots transfer phosphorus and other elements from lower soil layers to the top. After incorporation, the elements are available for the next crop. In summer, the catch crop creates a shade, eliminates the evaporation of moisture, and reduces the risk of erosion.

The DIRECTO NO direct seed drill is the best option for establishing catch crop. Direct catch crop seeding in uncultivated soil helps maintain moisture in the field and increases organic matter and humus content in soil. BEDNAR also offers a solution for seeding catch crop using the ALFA DRILL seeding unit or in combination with the FERTI-BOX FB, FERTI-CART FC or COMBO SYSTEM CS hoppers during soil cultivation. Crops can also be established using the universal OMEGA seed drills, or the wide EFECTA CE machines without any prior soil cultivation.

“The OMEGA OO_FL and EFECTA CE seed drills excel in their high variability of application, namely thanks to the double-chamber pressurised hopper and the option of a third hopper with the AFLA-DRILL seeding unit. This solution allows you to seed up to three crops at the same time, or to apply two types of fertiliser and seed one crop, all in one pass. The fertiliser and the seed depth can be set individually and independently of one another. This technical solution thus enables you to adjust to the new agronomic trends and modern crop establishment methods.”

In addition to the matter of properly functioning water and air soil regime, it is also necessary to address the matter of the nutrient supply in soil. The recent decrease in the number of livestock has led to the reduced application of organic fertilisers, which are currently mostly replaced with mineral fertilisers. The most frequently used fertilisers include nitrogen, phosphorus, potassium and calcium fertilisers.

The current knowledge of nutrient behaviour in soil is an important factor in choosing where in the soil profile to place fertilisers. The efficiency of specific fertilisers depends on their interaction with soil and on the ability to dissolve in water and its rate.

The application of fertiliser into the soil environment, known as profile fertilisation, should be carried out together with depth loosening using FENIX cultivators, combined ACTROS cultivators, or TERRALAND chisel ploughs. Such precisely placed fertiliser motivates the root system to grow faster and bigger, which helps solve current issues with soil moisture. This fertiliser placement system is most often used for establishing deep-rooting crops, such as corn, sugar beet, or oilseed rape.

Mostly phosphorus fertilisers, or combined ones with phosphorus content are applied in this fertilisation system, also nitrogen fertilisers with an ammonium nitrogen component, or fertilisers that contain sulphur are suitable.

A targeted application of fertiliser into tilled strips helps achieve very interesting results. The strips can be cultivated using the TERRASTRIP ZN deep cultivator, or the STRIP-MASTER EN cultivator. Those machines allow for fertiliser application in a single pass. In this case, the fertiliser is only applied in the processed strips at a specific depth. The fertiliser is easily accessible to the crop and the savings in the cost of fertilisers are considerable.

Machines for Strip-Till Cultivation

A wide application of the starter fertiliser should be done during seedbed preparation. The SWIFTER seedbed cultivators can be equipped with a set for fertiliser application in combination with FERTI-BOX hoppers. The fertiliser is then applied evenly and mixed in the top soil layer, where it is easily accessible to plants.

Fertiliser Hoppers

When weeding, it is recommended to apply liquid or mineral fertiliser by using the ROW-MASTER cultivator in combination with a solid fertiliser FERTI-BOX hopper or a liquid fertiliser FERTI-TANK hopper. The targeted application saves the costs and fertilisation during vegetation demonstrably increases the yield and the overall resistance of the crop to other undesirable effects, such as a long-lasting dry season.

“TO ACHIEVE THE REQUIRED YIELD, YOU NEED QUALITY SOIL AND ENOUGH WATER, AIR AND NUTRIENTS.”

Direct drilling into soil that has not been cultivated beforehand is a current trend in establishing both main crop and catch crop. Direct drill is a response to the ongoing increase in drought and water scarcity. The advantage of direct drilling lies in the elimination of soil moisture evaporation, reducing the risk of erosion, soil overheating, and weed growth. It increases the organic matter volume in the soil and significantly saves time and costs required for crop seeding.

The strip-till soil cultivation technology with simultaneous fertiliser application and seed placement in tilled strips offers many agronomic benefits, including erosion control, reduced field traffic, and water conservation. The chisel section ensures the removal of compacted soil layers and quality tilling of strips with the possibility of simultaneous fertiliser application. Subsequently, the seeds are placed in the tilled strips, providing plants with sufficient nutrients and promoting the development of a healthy root system.