OMEGA OO_L

3-9 m

100-400 hp

2 800-4 000 l

As the name implies, the DIRECTO NO seed drill is designed for direct drilling of various crops into uncultivated soil, stubble fields, catch crops or heavy and rocky soils. In one pass, you can seed up to three types of crops, or apply fertiliser with seed.

6-6 m

280-310 hp

5000 l

A seed drill for direct drilling and variable establishment of several crops in one pass, including the option of supplementary fertilisation.

The direct drilling technology completely differs from the used crop establishment methods. Direct drilling does not guarantee increased yields, but it can help you fight soil erosion and degradation. The considerable reduction in the number of passes reduces soil hardening and avoids disrupting soil capillarity. The soil cover of the field guarantees minimum moisture evaporation. The root system helps recover the soil structure.

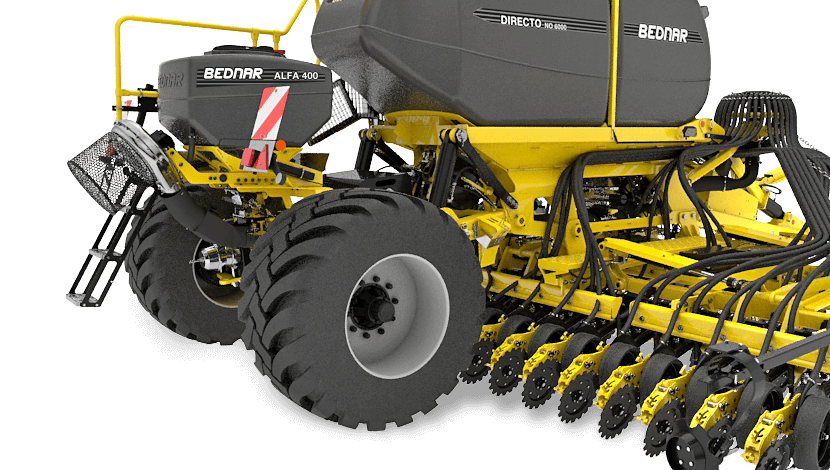

DIRECTO NO is equipped with a double-chamber pressurised hopper with a total capacity of 5,000 litres. The whole capacity of the double-chamber hopper can be used for drilling one type of crop or one chamber can be filled with fertiliser to be applied at the same time with the seed. In combination with the ALFA DRILL seeding unit, up to three types of seeds can be drilled or microgranulate applied at the same time in one pass.

The seeding coulters of the DIRECTO NO drill are arranged in two rows. The inter-row distance is 16.7 centimetres. The spacing of the individual drill coulters is a prerequisite for their high throughput, for example, when establishing crops in the catch crop or in large quantities of organic matter, such as mulch after harvesting corn for grain.

The ALFA DRILL seeding unit can be mounted to DIRECTO NO for concurrent establishment of three crops or for applying microgranulate. The seeding unit has a capacity of 400 litres.

The patented disc drill coulters deposit the seed into an identical sowing depth across the entire machine width and excellent contouring the uneven terrain in both longitudinal and lateral directions. The high down pressure of 250 kg per drill coulter guarantees quality seed placement, even in heavy soils. The minimum sowing depth is 2 cm. The inter-row distance is 16.7 cm for trouble-free throughput of the drill coulters through large quantities of crop residue.

The grain & fertiliser method means that seeds and fertiliser from the individual chambers are mixed in the pipeline and the final mixture is delivered to the distribution head. The fertiliser is immediately available for the seed in the ground during germination, improving the utilisation of the fertiliser and the development of the young crop. The second method when the fertiliser is applied below the seed makes it available for the plant in the later growth stage.

BEDNAR uses the pressurised hopper design in all seed drills. Overpressure is created in the hopper thanks to the airtight closure. This technical design allows for dosing large seeding amounts with high precision independent of the seed/fertiliser granule size.

In addition to the standard top hopper filling, DIRECTO NO also offers filling with the use of a screw conveyor. The screw conveyor is a part of the optional equipment for the machine. A suitable solution for filling the seed drill is through the rear dispensing window of the semi-trailer.

Easy control is a priority for the operators. DIRECTO NO is equipped with new BEDNAR EASY CONTROL software that guarantees easy and well-arranged control. The seed drill can be connected to the tractor via the ISOBUS technology, or it can be controlled using a BEDNAR ISOBUS display. A series of control displays with basic or advanced control functions are available.

BEDNAR developers designed an application for mobile phones that provides easy and simple calibration of the seed drill from your mobile phone. The mobile application includes a guide that helps with the right selection of the seeding roller based on the type of seeds/fertiliser, working speed and seeding amount.

The DIRECTO NO seed drill is equipped with large floating tyres with a dimension of 710/50 R26.5. The large tyres reduce pressure on soil and eliminate tracks when establishing crops in fields with high moisture levels. The seed drill does not exceed the transport width of 3 m.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the seed drill for direct drilling.

Contributes to excellent terrain contouring and easy connection to various types of tractor hitches.

A double-chamber hopper with the total capacity of 5,000 litres. The pressurised hopper offers high dispensing precision.

The ALFA DRILL seeding unit allows seeding another type of seeds or applying microgranulate by mixing the seeds or fertiliser in the pipeline.

The support wheels with mechanical setting stabilise the seed drill. The seed drill works in the plane and the set working depth is maintained.

It is used for comfortable filling of the double-chamber hopper of the seed drill, for example, using the emptying window in the trailer.

Suitable for increasing the weight of the seed drill to ensure quality crop establishment in difficult conditions.

The patented drill coulters with a high down pressure of 250 kg/drill coulter guarantee quality and even placement of seeds in the soil, even in difficult conditions.

The large floating tyres reduce pressure on soil and prevent the formation of tracks.

DIRECT SEEDING AS A CURRENT TREND

Direct seeding into soil that has not been cultivated beforehand is a current trend in establishing both main crop and catch crop. Direct seeding is a response to the ongoing increase in drought and water scarcity. The advantage of direct seeding lies in the elimination of soil moisture evaporation, reducing the risk of erosion, soil overheating, and weed growth. It increases the organic matter volume in the soil and significantly saves time and costs required for crop seeding.

| DIRECTO NO | NO 6000 | |

|---|---|---|

| Working width | m | 6 |

| Transport width | m | 2,9 |

| Transport length | m | 8,65 |

| Transport height | m | 3,86 |

| Drill coulter spacing | cm | 16,7 |

| Number of drill coulters | pcs | 36 |

| Fertilisation disc spacing | cm | 16,7 |

| Number of fertilisation discs | pcs | 36 |

| Drill coulter down pressure | kg | 250 |

| Hopper volume | l | 5000 |

| Hopper chamber ratio | 40:60 | |

| Filling height | m | 3,2 |

| Volume of BEDNAR ALFA DRILL hopper* | l | 400 |

| Drill coulters – diameter | cm | 45 |

| Closing wheels – diameter | cm | 38 |

| Guiding wheels – diameter | cm | 40 |

| Maximum axle load | kg | 7 500 |

| Maximum hitch load | kg | 4 000 |

| Transport tyre dimensions | 710/50 R26,5 | |

| Power demand | hp | 280 - 350 |

| Total weight** | kg | 11 000 |

* not included in the basic equipment ** according to the machine equipment