Simple front support wheels

Maintain the set working depth along the entire machine width, help with terrain contouring and prevent machine swinging.

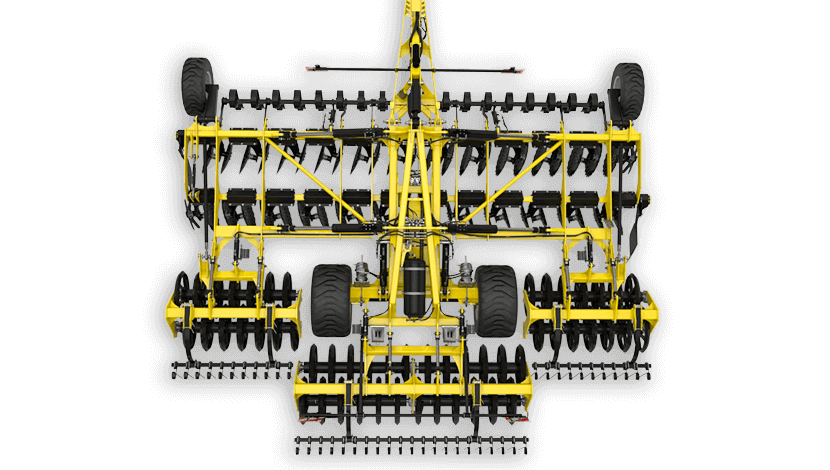

SWIFTERDISC XO_F is a versatile range of compact disc harrows available in working widths from 4 to 7.5 meters. This compact disc harrow was the first on the market with an integrated axle located in front of the rear packers. This solution offers even weight distribution and therefore high machine stability and the associated high working speed, which is essential for proper operation of a compact disc harrow.

2-14 cm

4-7,5 m

140-340 hp

Whether you need stubble cultivation or want to use your compact disc harrow for seedbed preparation, the SWIFTERDISC XO_F is the right choice.

Stubble cultivation is one of the most important operations. According to proper agrotechnical procedures, it should be performed as soon as possible after harvest. For this operation, the SWIFTERDISC XO_F can be equipped with notched discs or aggressive discs with a diameter of 520 × 5 or 560 × 5 mm, which ensure excellent cutting, mixing with the soil, and incorporation of plant residues. The rear packers then consolidate the soil and close the soil profile for even weed and volunteer seedlings emergence.

The optimal diameter of the discs, combined with high working speeds, allows high circumferential speeds of the discs to be achieved, ensuring excellent crumbling and mixing effects of the disc section. Especially for more frequent use in soil preparation, we recommend equipping the SWIFTERDISC XO_F compact disc harrow with a front levelling bar – Crushbar, which is used to level unevenness and break up rough furrows.

The double-row arrangement of the rear packers provides greater stability at high speeds than a single row, and also eliminates the gap in compact disc harrows with twin rollers in one row. The integrated axle ensures even weight distribution and eliminates swaying of the machine. It also makes transport safer and reduces the turning radius of the tractor with the harrow at headlands.

The working depth of the compact disc harrow is set easily on the rear packers. If the machine is equipped with front support wheels, their adjustment is automatic using mechanical connecting rods.

The SWIFTERDISC XO_F compact disc harrow can be equipped with a Trash Cutter cutting roller in front, which is ideal for cutting plant residues and tough stalks. The chopped crop residues decompose better in the soil and facilitate soil tillage without clogging the machine.

To increase year-round utilization, the SWIFTERDISC XO_F can be equipped with a hydraulically controlled Crushbar in front of it. This combination ensures perfect leveling of the soil profile, crumbling of clods, and seedbed preparation.

The SWIFTERDISC XO_F compact disc harrow can be equipped with the BEDNAR ALFA DRILL seeder for sowing catch crops and small-seeded plants during stubble cultivation in a single pass. The savings in time and fuel are significant in this case. The hopper capacity is 400 litres.

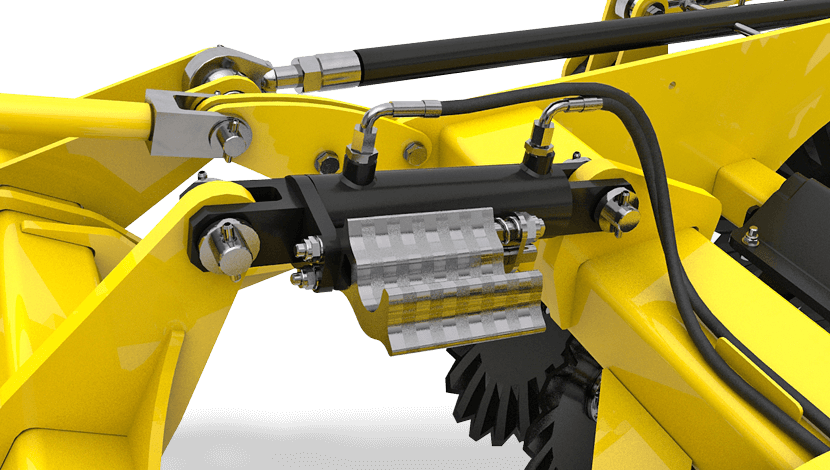

The SWIFTERDISC XO_F compact disc harrow is equipped with a hydraulic drawbar. We use this technical solution because it facilitates connection to the towing vehicle and, above all, improves the quality of work, as the compact disc harrow perfectly follows the unevenness of the terrain.

The integrated axle, positioned close to the tractor, ensures excellent driving characteristics. The working sections of the machine fold upwards, and the frames are conveniently secured using hydraulic locks. Smooth and safe transport with a transport width of up to 3 meters and a transport speed of up to 20 km/h.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise overview of the main working parts of the compact disc harrow.

A hydraulically adjustable drawbar contributes to perfect terrain contouring and levelling any unevenness.

It is used for levelling the rough furrow and for initial levelling in front of the disc working section.

Disc section with notched or aggressive discs, with a diameter of 520 / 560 × 5 mm.

Distributes weight evenly and contributes to the machine stability.

Help maintain stability and process soil evenly along the entire width.

A wide range of rear packers allows the machine to be adapted to specific conditions. The arrangement of the packers in two rows prevents the machine from rocking during operation. The packers help to reseal the soil surface and reduce soil moisture evaporation.

It perfectly levels any minor unevenness and evenly spreads clods along the entire machine width.

“We are very pleased with our purchase of the BEDNAR machine. This is going to be the second season. Last season, SWIFTERDISC processed over 1,000 hectares, it is a very versatile machine that can be used basically throughout the whole season. It is very stable thanks to the integrated axle and the hydraulically controlled drawbar, which can be set to a floating position. I also appreciate the low fuel consumption, about 6 l/ha. My neighbour has also recently purchased SWIFTERDISC after he saw how well it works at my farm.”

Francis Vaulot, farmer

France

We know that everyone has different requirements for machine equipment and its intended use. That’s why we allow you to specify your SWIFTERDISC XO_F compact disc harrow exactly as you require.