Simple front support wheels

Maintain the set working depth along the entire machine width, help with terrain contouring and prevent machine swinging.

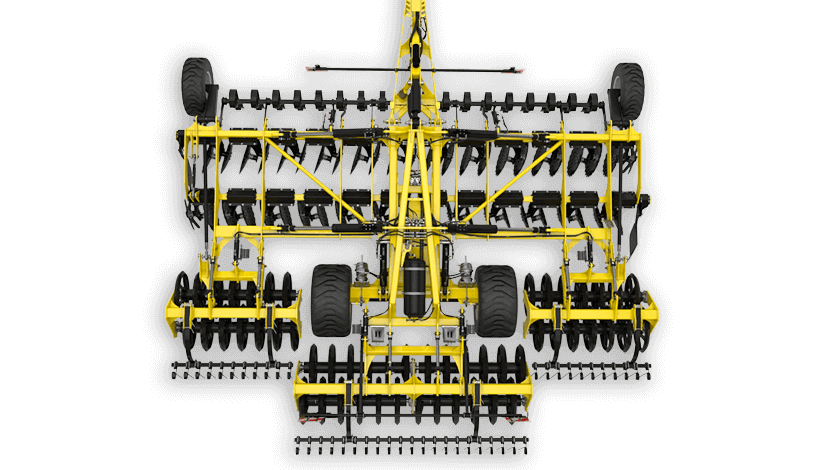

SWIFTERDISC XO_F is a versatile product line of short disc cultivators, available with a working width from 4 to 7,5 metres. This disc cultivator was the first on the market with an integrated axle, mounted in front of the rear packers. The design provides even weight distribution, and thus a high machine stability and the related high working speed, essential for the proper work of a disc cultivator.

2-14 cm

4-7.5 m

120-340 hp

Whether you need to cultivate a stubble field, or use you disc cultivator for seedbed preparation, SWIFTERDISC XO_F is the right choice.

Stubble cultivation is one of the most important field operations. According to the proper agricultural procedures, it should be done as soon after harvest as possible. For this operation, SWIFTERDISC XO_F can be equipped with notched or aggressive discs with a diameter of 520 × 5/ 560 × 5 mm, providing excellent cutting, mixing with soil and incorporation of crop residue. The rear packers consolidates soil and close the soil profile to ensure even emergence of weeds and unwanted cereal seeds.

The optimal disc diameter in combination with the high working speed provide a high circumferential speed of the discs, which leads to excellent crumbling and mixing effect of the disc section. If you are planning to use the disc cultivator for soil preparation more frequently, we recommend adding the front Crushbar levelling bar to SWIFTERDISC XO_F, for levelling unevenness and breaking the rough furrow.

The two-row layout of rear packers provides better stability at high speed than one row design, and also eliminates the gap in disc cultivators with two rollers in one row. The integrated axle ensures even distribution of the machine weight and eliminates its swaying. Moreover, it ensures safer transport and reduces the turning radius of the tractor with the cultivator at headland.

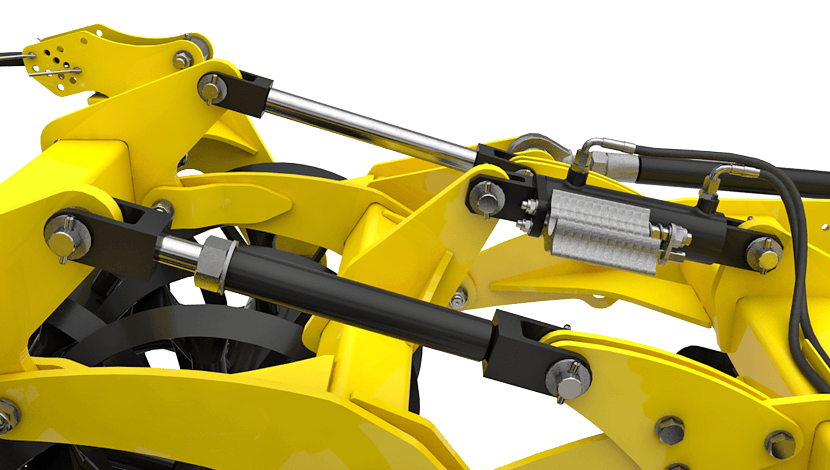

The working depth of the disc cultivator is easily set on the rear rollers. If the machine is equipped with front support wheels, they are set automatically using the mechanical connecting rods.

The SWIFTERDISC XO_F cultivator can be equipped with the Trash Cutter roller in the front, an ideal choice for cutting crop residue and hard stalks. Such cut crop residue decomposes better in soil and facilitates subsequent soil cultivation, preventing machine clogging.

To increase the all-year-round utilisation, SWIFTERDISC XO_F can be equipped with the hydraulically controlled Crushbar levelling bar in the front. This combination provides perfect soil profile levelling, clod crumbling, and soil preparation.

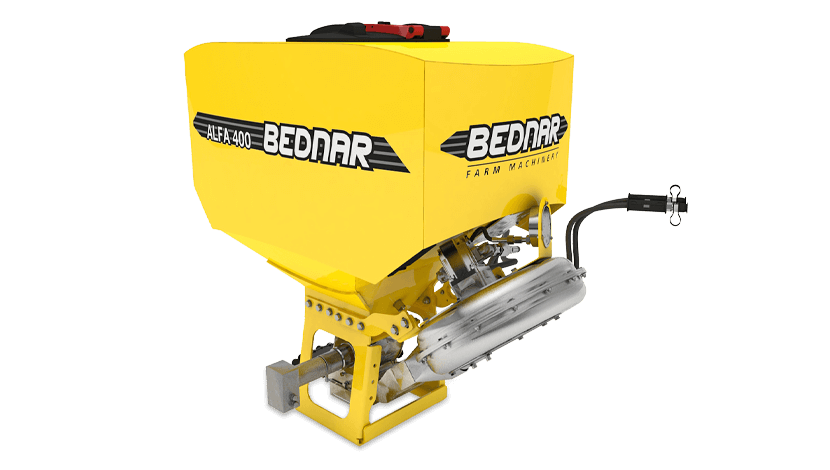

The SWIFTERDISC XO_F cultivator can be equipped with the BEDNAR ALFA DRILL seeding unit while in production, for seeding catch crop and small-seed plants during stubble cultivation, all in one pass. The time and fuel savings are considerable. The seeding unit has a capacity of 400 litres.

The SWIFTERDISC XO_F disc cultivator is equipped with a hydraulic drawbar. We use this technical design as it facilitates the connection to the tractor, and above all, improves the quality of work because the disc cultivator perfectly contours any terrain unevenness.

The integrated axle mounted near the tractor provides excellent driving abilities. The working sections are folded upwards; frames are comfortably secured using hydraulic locks. A smooth and safe transportation with a transport width of 3 metres and working speed up to 20 km/h.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the disc cultivator.

A hydraulically adjustable drawbar contributes to perfect terrain contouring and levelling any unevenness.

It is used for levelling the rough furrow and for initial levelling in front of the disc working section.

Disc section with notched or aggressive discs, with a diameter of 520 / 560 × 5 mm.

Distributes weight evenly and contributes to the machine stability.

Help maintain stability and process soil evenly along the entire width.

The wide range of rear packers make it possible to adjust the machine to any conditions. Two-row packer layout prevents machine swaying during work. The packers help close the surface and reduce evaporation of soil moisture.

It perfectly levels any minor unevenness and evenly spreads clods along the entire machine width.

“We are very pleased with our purchase of the BEDNAR machine. This is going to be the second season. Last season, SWIFTERDISC processed over 1,000 hectares, it is a very versatile machine that can be used basically throughout the whole season. It is very stable thanks to the integrated axle and the hydraulically controlled drawbar, which can be set to a floating position. I also appreciate the low fuel consumption, about 6 l/ha. My neighbour has also recently purchased SWIFTERDISC after he saw how well it works at my farm.”

Francis Vaulot, farmer

France

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTERDISC XO_F cultivator to precisely match your needs.