WHAT DO THE FARMERS HAVE TO SAY?

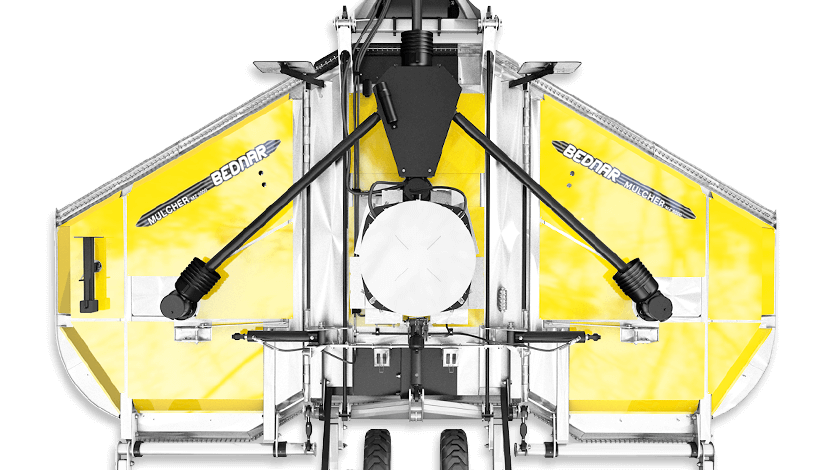

“We decided to purchase the machine after we saw a demonstration in a grain maize stubble field and meadow grass. We tried competitive hammer cutters in the same conditions, but the quality of work did not meet our demands. Therefore, the MULCHER MZ 6000 rotary cutter was the obvious choice; it worked perfectly in the stubble field as well as in the meadows. Another decisive factor was that the rotary cutter with a working width of 20 feet does not need such a towing power as the competitive machines.”

Pavel Joneš,

a machine operator, ZOD Rasošky, Rasošky (district of Náchod, CZ)

BEDNAR FMT

BEDNAR FMT