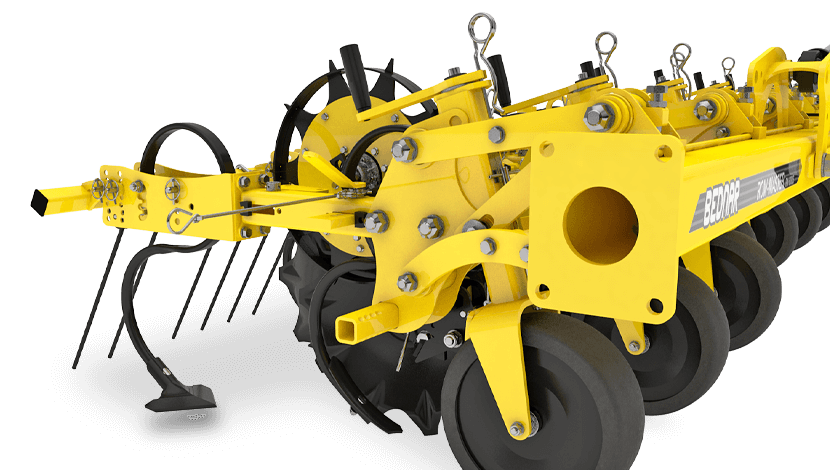

Protective discs

The specially shaped protective discs of the working units define the cultivation width – they protect leaves and roots. The discs also prevent covering crop rows with soil and weed seeds.

The ROW-MASTER RN_S cultivator is designed for weeding inter-rows, removing the soil crust, eliminating the growth of weeds, and creating a proper soil climate in sugar beet crop. The cultivator can be easily adjusted for an inter-row spacing of 17.7-19.7 inches and equipped with various equipment to adjust to the specific crop condition. To reduce the risk of damaging plants and to achieve a high output, the cultivator can be equipped with the self-guiding CultiCam system.

1-5 in

20-40 ft

70-200 hp

A inter-row cultivator that eliminates the occurrence of weeds in sugar beet crop with an adjustable inter-row spacing of 17.7-19.7 inches.

Sugar beet needs an ideal soil environment to achieve adequate yield-generating elements. Weeding is one of the options how to achieve that. It makes air accessible to the roots, disrupts the soil crust, removes weed plants from inter-rows, and increases the sugar content of tubers.

A great advantage of the ROW-MASTER RN_S cultivator is the high variability of the equipment. The different types of working sections make it possible to adjust the cultivator to the current growth stage of the crop so that loosening is performed as best as possible and without the risk of crop damage.

Early spring inter-row cultivation should be done using 5.9 inches sweeps with 100% overlapping. This operation removes the soil crust and weeds in rows. Sweeps bring weed roots to the surface where they quickly wilt.

For the second weeding, the cultivator should be equipped with a working section with three 5.9 inches sweeps and two chisels with a width of 1.5 inches. The chisels do not damage the plant air roots and moreover, they create a groove in the soil profile that improves access of roots to water and air.

The final loosening should be done using the 2.4 inches backfilling chisel with a mouldboard. The large chisel loosens soil and removes soil crust, even very hard. The mouldboard reduces the tops. This has a direct effect on the final tuber assessment.

The individual working units are mounted to the frame using a clamp. The parallelogram traces the terrain and maintains the set working depth of the cultivation units in a precise way. The parallelogram completely eliminates movements caused by unevenness.

Each working unit is mounted on a parallelogram, placed on silent-blocks. The down pressure of the working units is provided by the unique method of mounting in two pairs of silent-blocks. The down pressure of up to 176 lb per unit ensures that the set depth is maintained even in extremely hard and difficult conditions.

The ROW-MASTER RN_S cultivator is equipped with stabilizing steel wheels of the side frames that keep the cultivator within the rows. Each working unit has its own support wheel that helps maintain the set working depth and trace the terrain.

CultiCam, a guiding camera, reads the row lines, transfers the information to the system that sends data to the control unit, which transmits signals to the electric valves that move the frames to the left, or right. The camera can guide working units from the very early stage of crop emergence and it considerably increases productivity and comfort of work.

The inter-row cultivator can be equipped with a set of LED work lighting that ensures trouble-free visibility around the machine during long work shifts, to guarantee maximum daily output, even when working at night.

The spacing between the individual working units can be easily changed by loosening the bolts that connect the main machine frame with the working units. The working depth of each unit is set easily using a manual screw mechanism (a crank). The working depth can be set from 0.8 to 4.7 inches.

The FERTI-BOX FB_F front mounted hopper is designed for supplementary fertilisation in the soil profile and has a capacity of 54 – 62 bu. Fertiliser is pneumatically distributed from the front hopper to the distribution head mounted on the inter-row cultivator.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the inter-row cultivator.

Easy connection to the three-point hitch of the tractor. Category II/III hitch

Maintain the set working depth and perfectly trace the terrain.

The system automatically moves the cultivator to the side based on data received from the CultiCam guidance system.

An extremely robust frame with clearance of 31,5 inches for weeding corn or sunflower crops.

The innovative design increases down pressure and enables easy penetration of the working unit in the soil.

The individual working units are mounted on a parallelogram. The system provides perfect terrain tracing and maintains the set working depth.

“I am very pleased with the inter-row cultivator. This year, we planted sugar beet on an area of 130 hectares. I can process about 30 hectares during a ten-hour shift. The working speed is around 6.5 km/h; the machine could work faster but it’s quality that matters, we do not want the sugar beet covered by soil. It all depends on the conditions and the size of sugar beet. Operation is easy. It is a smart machine – it notifies you when there is a problem. Working with the camera for automatic guidance is perfect. I also appreciate the easy maintenance and machine design with maintenance-free systems, as well as the simple working depth setting without the need to use a special tool. It takes me about ten minutes to pre-set the depth.”

Tomáš Bartoš, Machine Operator

UNIAGRO, s.r.o.

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own ROW-MASTER RN inter-row cultivator to precisely match your needs.