Doppie ruote di appoggio anteriori

Fornisce un eccellente tracciamento del terreno e mantiene la profondità di lavoro impostata lungo l’intera larghezza della macchina

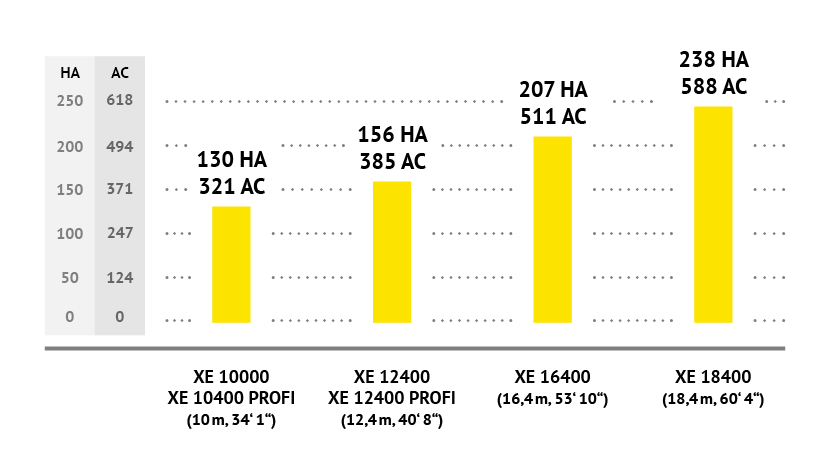

Un design consolidato e la massima resa giornaliera. Questi sono i principali vantaggi del coltivatore a dischi larghi SWIFTERDISC XE. Le sue proprietà lo rendono adatto alla preparazione di terreni poco profondi e alla miscelazione intensa dei residui colturali con il terreno. I coltivatori SWIFTERDISC XE sono disponibili con una larghezza di lavoro di 10 e 12,4 metri. Il design unico della piegatura in avanti della sezione del disco consente di raggiungere dimensioni compatte per il trasporto.

2-14 cm

10-12.4 mt

350-500 hp

I coltivatori SWIFTERDISC XE offrono una serie di soluzioni tecniche che li rendono adatti sia alla frantumazione superficiale delle stoppie che alla preparazione del letto di semina.

La rottura delle stoppie è una delle operazioni più importanti sul campo. Secondo le corrette procedure agricole, dovrebbe essere fatto il prima possibile dopo la raccolta. Per questa operazione lo SWIFTERDISC XE può essere dotato di dischi seghettati o aggressivi con un diametro di 520 × 5 mm o 560 x 5 mm, fornendo un eccellente taglio, miscelazione con il terreno e incorporazione dei residui colturali. I rulli posteriori compattano il terreno e chiudono il profilo del terreno coltivato per garantire l’emersione uniforme di erbe infestanti e semi di cereali indesiderati.

Il diametro ridotto del disco in combinazione con un’elevata velocità di lavoro forniscono un’alta velocità circonferenziale dei dischi, che porta a un eccellente effetto di sminuzzamento e miscelazione della sezione del disco. Se avete intenzione di utilizzare il coltivatore a disco per la preparazione del terreno più frequentemente, vi consigliamo di aggiungere il livellatore Crushbar anteriore al SWIFTERDISC XE per livellare e rompere il solco ruvido.

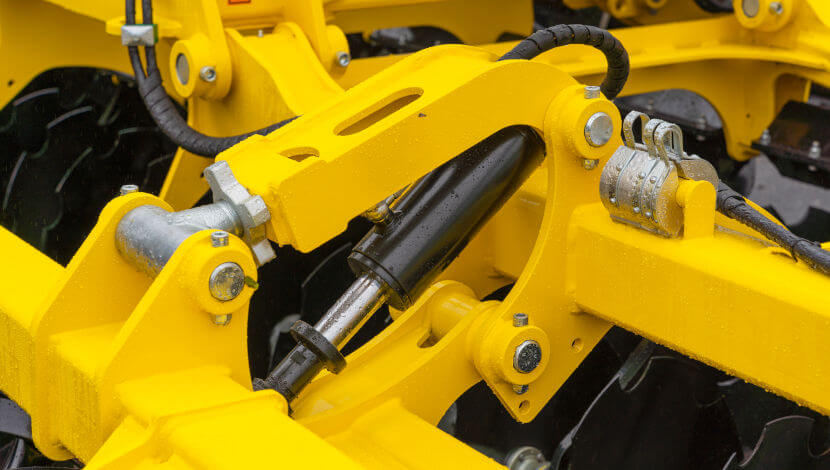

La profondità di lavoro richiesta viene impostata con precisione tramite l’idraulica. La profondità di lavoro della macchina può essere facilmente impostata utilizzando clip di ribaltamento sui cilindri idraulici del coltivatore a dischi.

Per aumentare l’utilizzo durante tutto l’anno, il coltivatore SWIFTERDISC XE può essere equipaggiato con il livellatore Crushbar a comando idraulico nella parte anteriore. Questa combinazione fornisce un perfetto livellamento del profilo del suolo, lo sbriciolamento delle zolle e la preparazione del suolo.

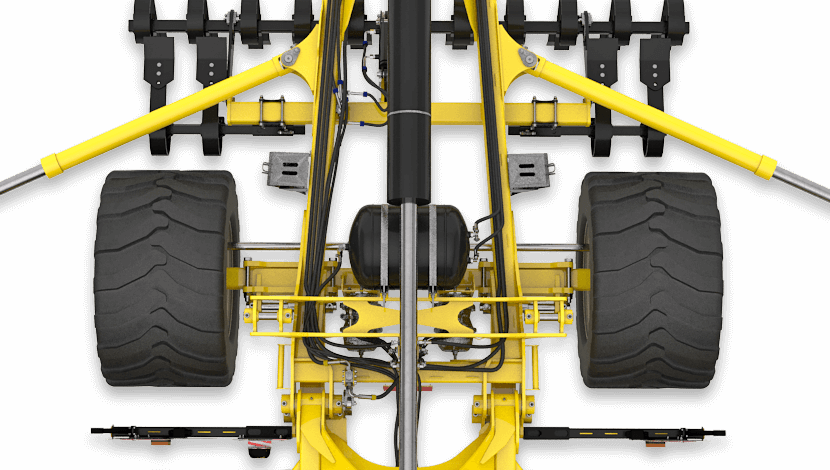

i coltivatori a dischi larghi SWIFTERDISC XE hanno l’asse di trasporto spostato in avanti, davanti alla prima fila di sezioni dei dischi. Questo design contribuisce alla distribuzione ideale del peso e consente di raggiungere velocità di lavoro più elevate. Le bielle telescopiche aiutano a stabilizzare i telai dove sono montate le sezioni del disco.

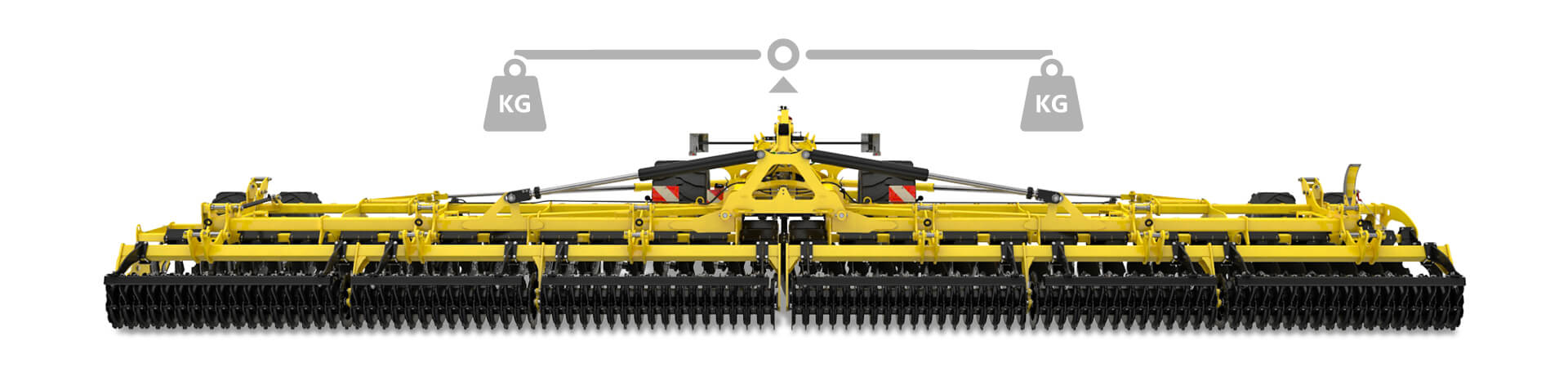

Il mantenimento della profondità di lavoro impostata per un’elaborazione uniforme del profilo del suolo è alla base di una coltivazione del suolo di qualità. I coltivatori SWIFTERDISC XE forniscono la stessa pressione sui dischi lungo l’intera larghezza della macchina grazie all’asse spostato in avanti e al concetto di due telai laterali pieghevoli. Il design strutturale della macchina riduce il numero di cilindri idraulici in cui la pressione del telaio laterale potrebbe andare persa. Questo design riduce anche il numero di punti di lubrificazione, l’usura complessiva della macchina e semplifica la manipolazione con la macchina, sia in campo che su strada.

Il coltivatore a dischi larghi SWIFTERDISC XE è facilmente manovrabile in capezzagna. La macchina gira sui rulli posteriori e sulle ruote di appoggio anteriori, solo la sezione a dischi viene sollevata senza la necessità di sollevare l’intero telaio. Questo design elimina il carico negativo sull’attacco e scarica il trattore quando la macchina è in posizione di capezzagna.

Anche con la larghezza di lavoro di 12,4 m, il coltivatore SWIFTERDISC XE è molto compatto in modalità di trasporto, perché non supera la larghezza di trasporto di 3 metri e l’altezza della macchina è appena inferiore a 4 metri. Tali parametri vengono raggiunti grazie al ripiegamento del telaio laterale in avanti, verso il timone.

Il coltivatore SWIFTERDISC XE può essere equipaggiato con l’unità di semina BEDNAR ALFA DRILL durante la produzione, per seminare colture intercalari e piccoli semi durante la rottura della stoppia, il tutto in un solo passaggio. Notevole il risparmio di tempo e di carburante. L’unità di semina ha una capacità di 800 litri.

I coltivatori SWIFTERDISC ad ampia portata sono progettati per l’aggregazione con i trattori più potenti sul mercato. Questi coltivatori offrono la massima resa giornaliera grazie al loro design sofisticato e all’elevata velocità di lavoro.

Non esitare a contattarci o a trovare il rivenditore per la tua zona.

Contattaci Trova un concessionarioUn riassunto delle principali parti di lavoro del coltivatore a dischi larghi.

Fornisce una distribuzione ideale del peso della macchina e contribuisce alla precisa aderenza alla profondità di lavoro impostata grazie alla pressione identica sulla sezione del disco.

Fornisce un eccellente livellamento del terreno e mantiene la profondità di lavoro impostata lungo l’intera larghezza della macchina.

La barra livellatrice a comando idraulico è particolarmente indicata per il livellamento iniziale della superficie e per la rottura del solco grezzo prima della sezione del disco. Le singole strisce livellatrici sono rinforzate. È facilmente controllabile tramite il circuito idraulico dalla comodità della cabina.

Sezione del disco con dischi seghettati o aggressivi, con un diametro di 520 / 560 × 5 mm, e un’elevata produttività grazie al sistema Twin-Disc.

Fornisce una svolta sicura a fine campo e consente la piegatura del telaio laterale anteriore.

l’ampia gamma di rulli posteriori consente di adattare la macchina a qualsiasi condizione

Siamo consapevoli che ognuno ha requisiti diversi per l’equipaggiamento opzionale della macchina in relazione al suo utilizzo. Pertanto, puoi personalizzare il tuo coltivatore SWIFTERDISC XE per soddisfare esattamente le tue esigenze.