Ruedas de apoyo delanteras dobles

Proporciona un excelente seguimiento del terreno y mantiene la profundidad de trabajo establecida a lo largo de todo el ancho de la máquina.

Un diseño bien establecido y el máximo rendimiento diario. Esas son las principales ventajas del cultivador de discos anchos SWIFTERDISC XE. Sus propiedades lo hacen adecuado para la preparación de suelos poco profundos y la mezcla intensa de residuos de cultivos con el suelo. Los cultivadores SWIFTERDISC XE están disponibles con una anchura de trabajo de 10 y 12,4 metros. El diseño único del plegado de la sección del disco delantero le permite lograr dimensiones compactas para el transporte.

2-14 cm

10-12.4 m

350-450 hp

Los cultivadores SWIFTERDISC XE ofrecen una serie de soluciones técnicas que los hacen adecuados tanto para el desbroce superficial como para la preparación del lecho de siembra.

La roturación de rastrojos es una de las operaciones de campo más importantes. De acuerdo con los procedimientos agrícolas adecuados, debe hacerse tan pronto como sea posible después de la cosecha. Para esta operación, el SWIFTERDISC XE CLASSIC puede equiparse con discos dentados o agresivos con un diámetro de 520 × 5 mm o 560 x 5 mm, proporcionando un excelente corte, mezcla con el suelo e incorporación de residuos de cultivo. Los compactadores traseros compactan el suelo y cierran el perfil del suelo cultivado para garantizar la aparición uniforme de malas hierbas y semillas de cereales no deseadas.

El pequeño diámetro del disco en combinación con una alta velocidad de trabajo proporciona una alta velocidad circunferencial de los discos, lo que conduce a un excelente efecto de desmenuzado y mezclado de la sección del disco. Si planea usar el cultivador de discos para la preparación del suelo con más frecuencia, le recomendamos agregar el nivelador delantero Crushbar al SWIFTERDISC XE para nivelar y romper el surco irregular.

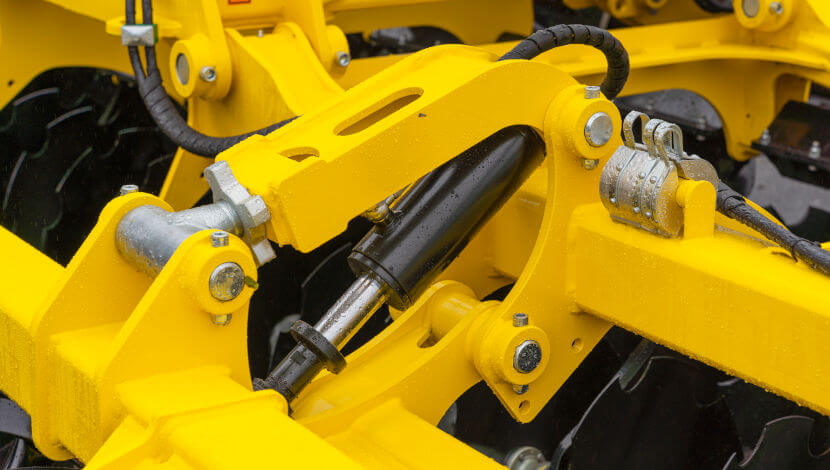

La profundidad de trabajo necesaria se ajusta con precisión mediante el sistema hidráulico. La profundidad de trabajo de la máquina se puede ajustar fácilmente mediante clips basculantes en los cilindros hidráulicos del cultivador de discos.

Para aumentar la utilización durante todo el año, el cultivador ancho SWIFTERDISC XE puede equiparse con el nivelador Crushbar controlado hidráulicamente en la parte delantera. Esta combinación proporciona una nivelación perfecta del perfil del suelo, desmoronamiento de terrones y preparación del suelo.

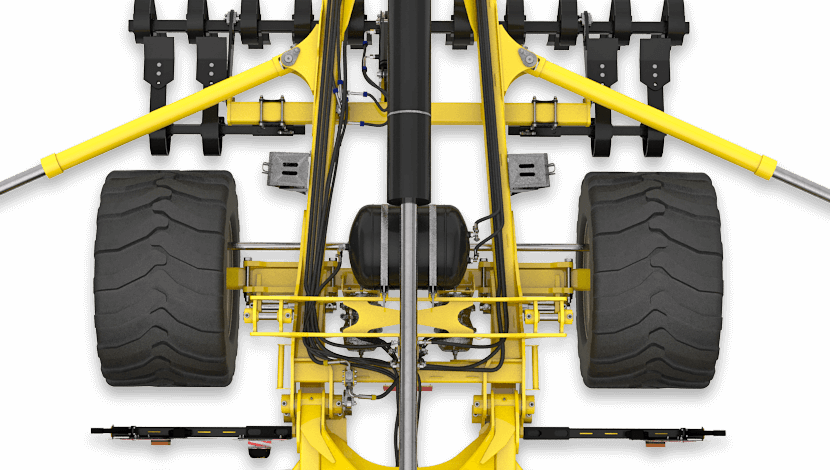

Los cultivadores de discos anchos SWIFTERDISC XE tienen el eje de transporte desplazado hacia delante, delante de la primera fila de la sección de discos. Este diseño contribuye a una distribución ideal del peso y le permite alcanzar mayores velocidades de trabajo. Las bielas telescópicas ayudan a estabilizar los marcos donde se montan las secciones del disco.

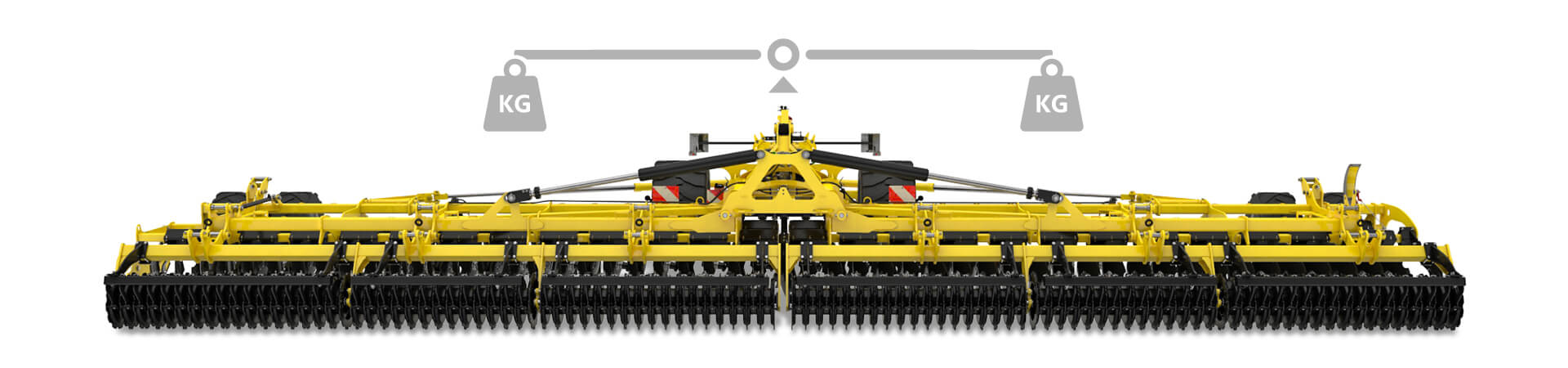

Mantener la profundidad de trabajo establecida para un procesamiento uniforme del perfil del suelo es la base de un cultivo del suelo de calidad. Los cultivadores SWIFTERDISC XE proporcionan la misma presión sobre los discos en todo el ancho de la máquina gracias al avance del eje y al concepto de dos bastidores laterales plegables. El diseño estructural de la máquina reduce el número de cilindros hidráulicos en los que podría perderse la presión del bastidor lateral. Este diseño también reduce el número de puntos de lubricación, el desgaste general de la máquina y simplifica la manipulación con la máquina, tanto en el campo como en la carretera.

El cultivador de discos anchos SWIFTERDISC XE se maniobra fácilmente en las cabeceras. La máquina gira los rodillos traseros y las ruedas de apoyo delanteras en las cabeceras, solo se levanta la sección del disco sin necesidad de levantar todo el bastidor. Este diseño elimina la carga negativa en el enganche y descarga el tractor cuando la máquina está en la posición de cabecera.

Incluso con un ancho de trabajo de 12,4 m, el cultivador SWIFTERDISC XE es muy compacto en modo de transporte, ya que no supera los 3 metros de ancho de transporte y la altura de la máquina está justo por debajo de los 4 metros. Dichos parámetros se logran gracias al plegado del bastidor lateral delantero, hacia la barra de tiro.

El cultivador SWIFTERDISC XE puede equiparse con la unidad de siembra BEDNAR ALFA DRILL durante la producción, para sembrar cultivos intermedios y plantas de semillas pequeñas durante el desbroce, todo en una sola pasada. El ahorro de tiempo y combustible es considerable. La unidad de siembra tiene una capacidad de 800 litros.

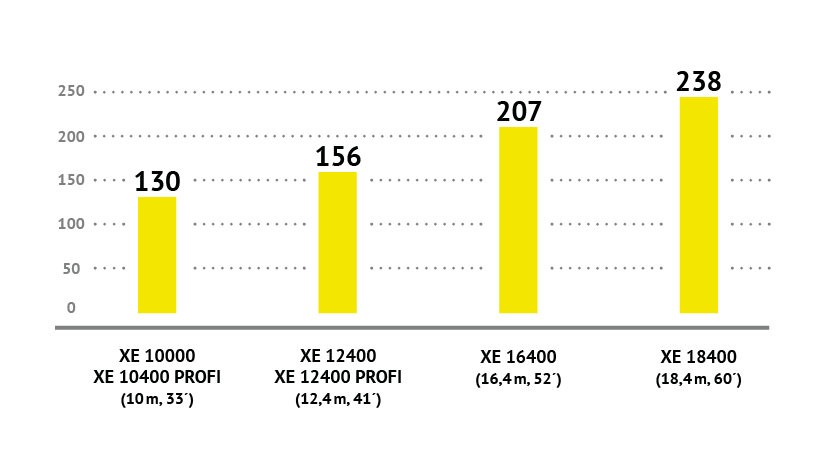

Los cultivadores SWIFTERDISC de gran envergadura están diseñados para combinarse con los tractores más potentes del mercado. Estos cultivadores ofrecen el máximo rendimiento diario gracias a su sofisticado diseño y alta velocidad de trabajo.

No dude en ponerse en contacto con nosotros o encontrar el distribuidor de su zona.

Contacte con nosotros Encontrar un distribuidorUn resumen conciso de las principales partes de trabajo del cultivador de discos anchos.

Proporciona una distribución ideal del peso de la máquina y contribuye al cumplimiento preciso de la profundidad de trabajo establecida gracias a la presión idéntica en la sección del disco.

Proporciona un excelente seguimiento del terreno y mantiene la profundidad de trabajo establecida en todo el ancho de la máquina.

El nivelador Crushbar controlado hidráulicamente es especialmente adecuado para la nivelación inicial de la superficie y para romper el surco irregular antes de la sección del disco. Las tiras niveladoras individuales están reforzadas. Se controla fácilmente mediante el circuito hidráulico desde la comodidad de la cabina.

Sección de disco con discos dentados o agresivos, con un diámetro de 520 / 560 × 5 mm, y alto rendimiento gracias al sistema Twin-Disc.

Proporciona un giro seguro en las cabeceras y permite el plegado del bastidor lateral delantero.

La amplia gama de compactadores traseros y rodillos permite adaptar la máquina a cualquier condición.

Sabemos que todos tienen diferentes requisitos para el equipo opcional de la máquina y su uso esperado. Por lo tanto, puede especificar su propio cultivador de discos anchos SWIFTERDISC XE para satisfacer exactamente sus necesidades.