Dual gauge wheels

Provide excellent terrain contouring and maintain the set working depth across the entire implement width.

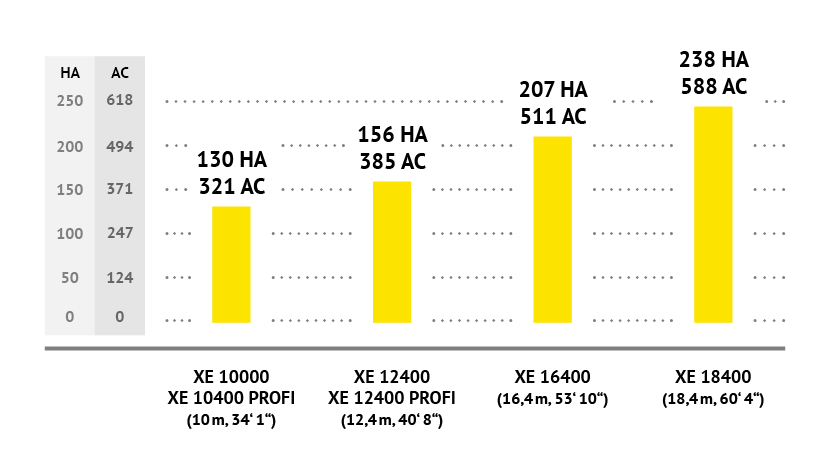

A well-established design and maximum daily output. Those are the main advantages of the SWIFTERDISC XE high speed disc. Its properties make it suitable for shallow tillage and intense mixing of trash with soil. SWIFTERDISC XE speed discs are available with a working width of 32′ 10″ and 40′ 8″. The unique design of forward blade gang folding allows it to achieve compact dimensions for transport.

0.5"-5.5" in

32' 10"-40' 8" ft

350-500 hp

SWIFTERDISC XE speed discs offer a series of technical solutions that make them suitable for both tillage and seedbed preparation

Tillage is one of the most important field operations. According to the proper agricultural procedures, it should be done as soon after harvest as possible. For this operation the SWIFTERDISC XE can be equipped with notched or aggressive blades with a diameter of 20″×0.2″ or 22″×0.2″, providing excellent cutting, mixing with soil and incorporation of trash. The rear packers consolidate soil and close the cultivated soil profile to ensure even emergence of weeds and unwanted cereal seeds.

The small blade diameter in combination with a high working speed provide a high circumferential speed of the discs, which leads to excellent crumbling and mixing effect of the blade gang. If you are planning to use the high speed disc for seedbed preparation more frequently, we recommend adding the front Crushbar levelling bar to the SWIFTERDISC XE for levelling and breaking the rough furrow.

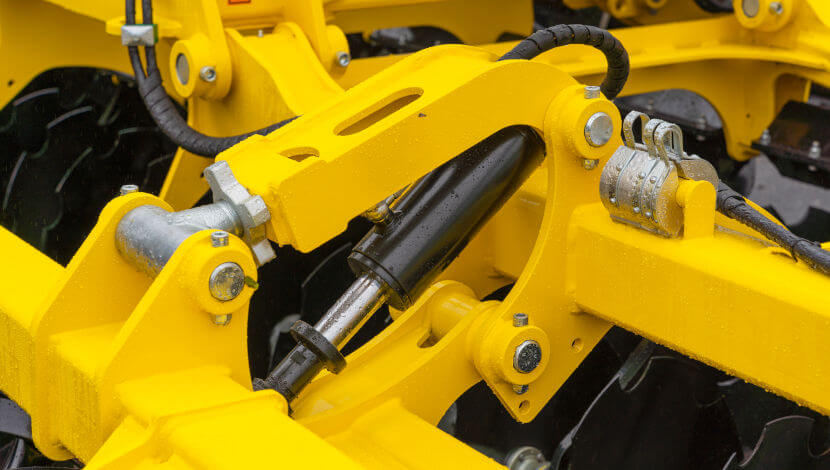

The required working depth is set precisely using hydraulics. The implement working depth can be easily set using tipping spacers on the hydraulic cylinders of the speed disc.

To increase the all-year-round utilisation, the SWIFTERDISC XE high speed disc can be equipped with the hydraulically controlled Crushbar levelling bar in the front. This combination provides perfect soil profile levelling, clod crumbling, and seedbed preparation.

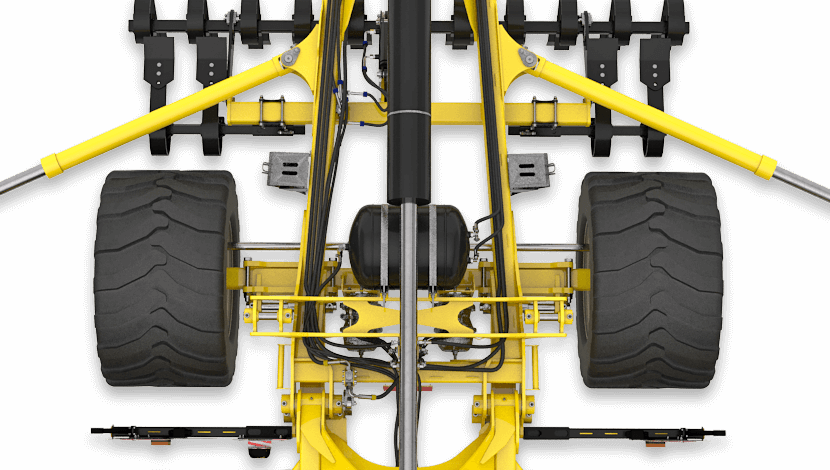

The SWIFTERDISC XE high speed disc have the transport axle shifted forward, in front of the first blade gang. This design contributes to ideal weight distribution and allows it to achieve higher working speeds. The telescopic connecting rods help stabilise frames where the disc gang are mounted.

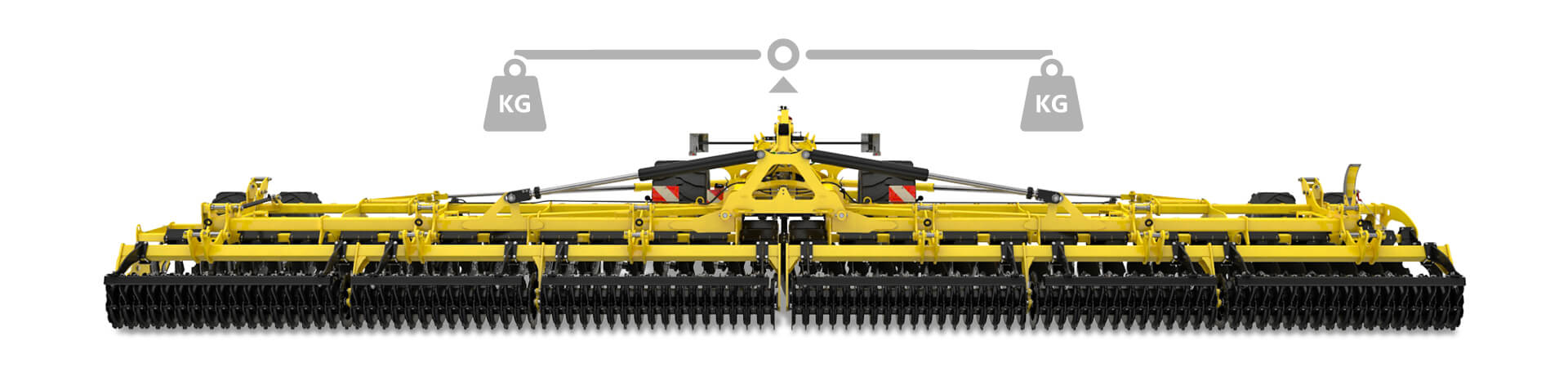

Maintaining the set working depth for even soil profile processing is the foundation of quality tillage. The SWIFTERDISC XE speed discs provide the same pressure on discs along the entire tool width thanks to the axle being moved forward and the concept of two folding side frames. The structural design of the machine reduces the number of hydraulic cylinders where side frame pressure could be lost. This design also reduces the number of points of lubrication, the overall wear of the implement, and it simplifies manipulation with the machine, both in the field and on the road.

The SWIFTERDISC XE high speed disc is easily manoeuvred at headlands. The speed disc turns on the rear rollers and gauge wheels at headlands, only the blade gang is lifted up without the need to lift up the entire frame. This design eliminates the negative load on the hitch and unloads the tractor when the implement is in the headland position.

Even with the working width of 40′ 8″, the SWIFTERDISC XE high speed disc is very compact in transport mode, because it does not exceed the transport width of 9′ 10″ and the height of the machine is just below 13′ 1″. Such parameters are achieved thanks to the forward side frame folding, towards the drawbar.

The SWIFTERDISC XE speed disc can be equipped with the BEDNAR ALFA DRILL seeder while in production, for seeding cover crop and small-seed plants during tillage, all in one pass. The time and fuel savings are considerable. The seeder has a capacity of 22 bu.

The large SWIFTERDISC high speed disc are designed for connection with the most powerful tractors on the market. These speed discs offer maximum daily output thanks to their sophisticated design and high working speed.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working tools of the high speed disc

Provides ideal distribution of the implement weight and contributes to precise adherence to the set working depth thanks to the identical pressure on the blade gang.

Provides excellent terrain contouring and maintains the set working depth along the entire width of the implement.

The hydraulically controlled Crushbar levelling bar is especially suitable for initial surface levelling and for breaking the rough furrow in front of the blade gang. The individual leveller paddles are reinforced. It is easily controlled using the hydraulic circuit from the comfort of the cabin.

Blade gang with notched or aggressive discs, with a diameter of 20″ / 22″×0.2″ , and high throughput thanks to the Twin-Disc system.

Provides safe turning at headlands and enables the forward side frame folding.

The wide range of rear packers and rollers makes it possible to adjust the machine to any conditions.

We know that everyone has different requirements for the optional implement equipment and its expected use. Therefore, you can specify your own SWIFTERDISC XE speed disc to precisely match your needs.