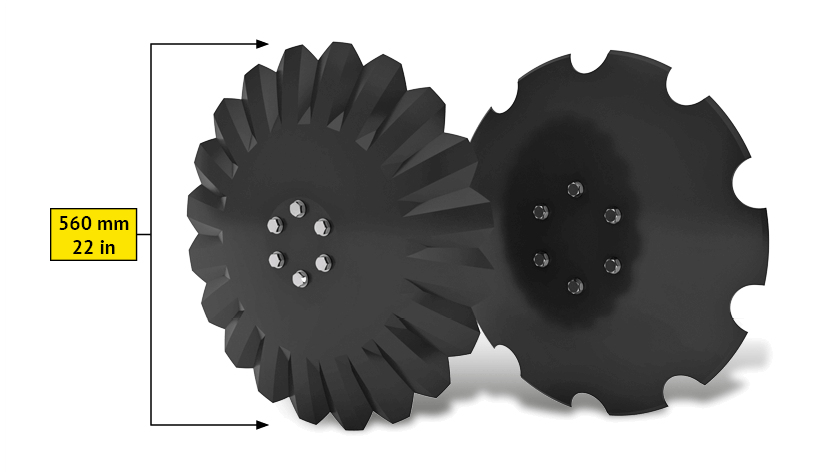

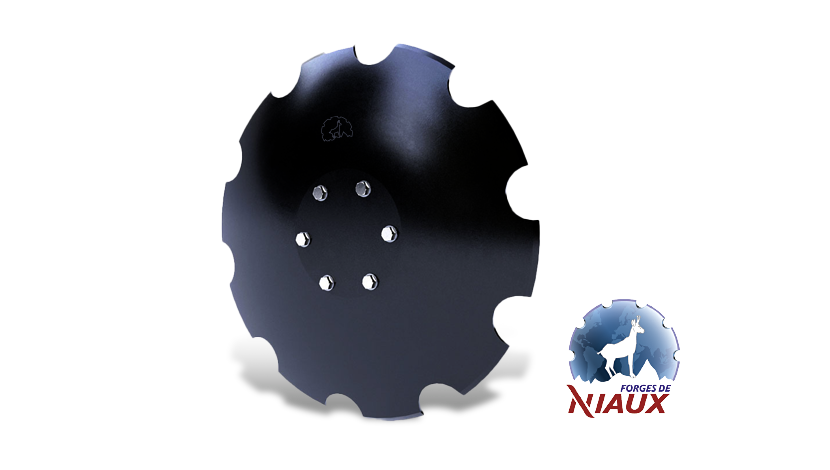

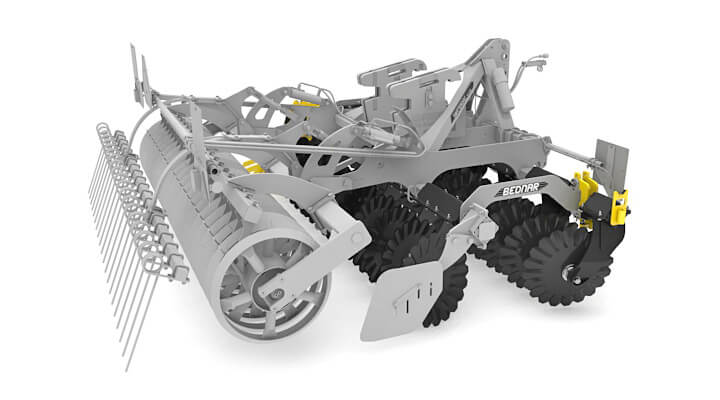

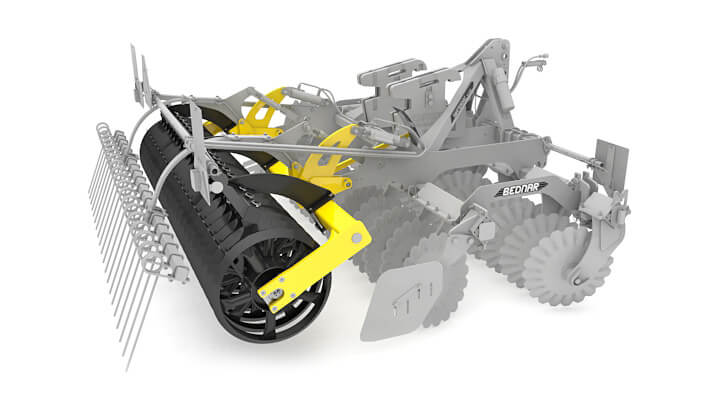

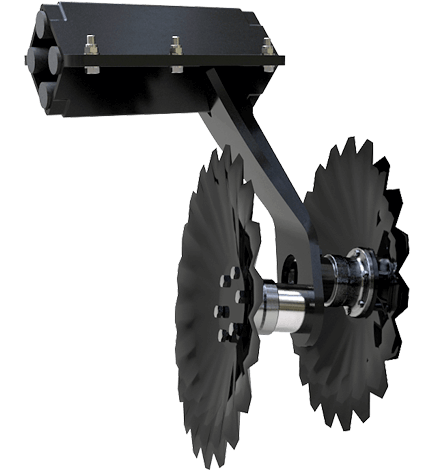

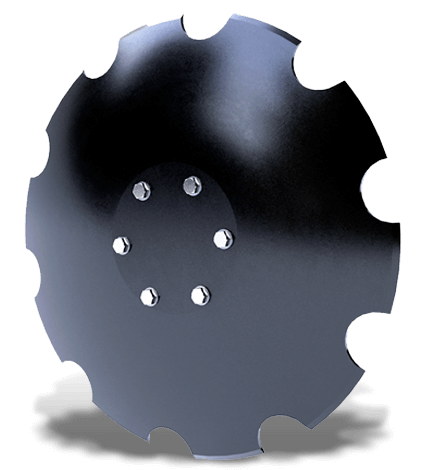

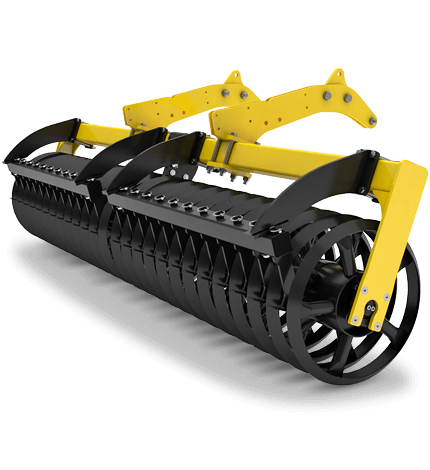

Aggressive discs

The specially shaped discs offer a higher cutting and mixing effect. They also penetrate soil better in the dry season. The aggressive discs have a lot of cutting edges along the circumference for easy incorporation of a large quantity of crop residue. The discs are available with a diameter of 520 or 560 mm.

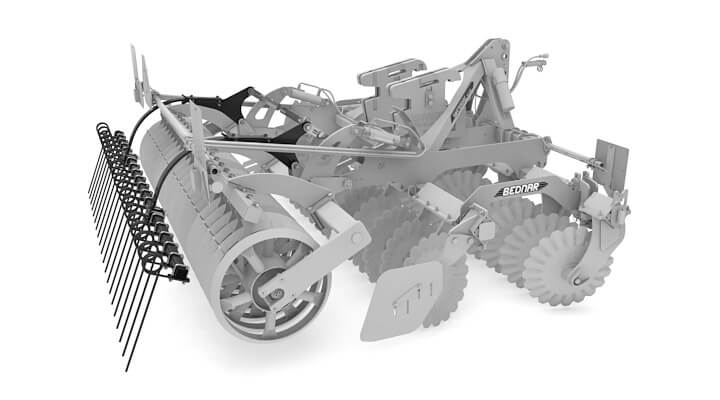

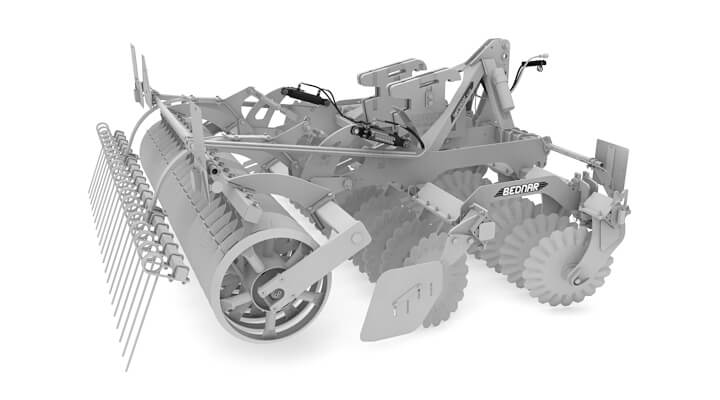

BEDNAR FMT

BEDNAR FMT