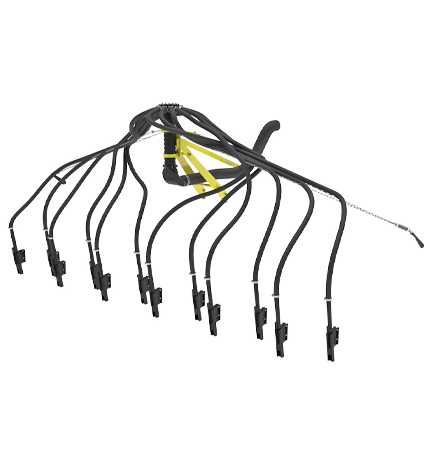

Set for mineral fertiliser application

The set includes a distribution head with hoses leading to the individual cultivation units.

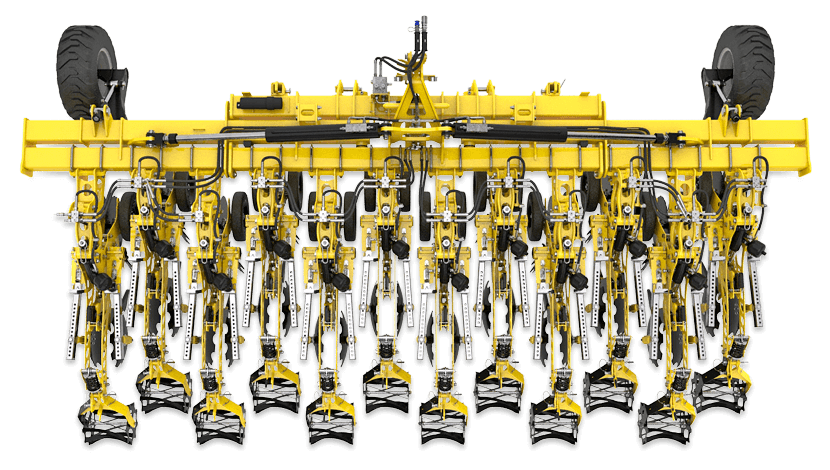

The STRIP-MASTER EN cultivator is designed for strip-till soil cultivation. This technology is especially suitable for establishing wide-row crops. The STRIP-MASTER EN cultivator processes soil in strips of 80 cm, 75 cm, 70 cm, 50 cm and 45 cm at a depth of up to 35 cm. The machine has a versatile frame that allows setting the required spacing for the preparation of strips for a specific crop.

35 cm

4,8 -6 m

180 -400 hp

A strip-till cultivator for strip-till cultivation up to a depth of 35 centimetres with an adjustable inter-row spacing of 45-80 centimetres.

The advantages of strip-till cultivation include a faster warming and a better aeration of the processed soil strips, a reduced erosion, a better water absorption when compared with direct drilling, or a targeted application of mineral or organic fertiliser into strips.

The inter-row space usually contains some crop residue that covers the uncultivated strips in the field. It reduces the evaporation of soil moisture. The crop residue in the inter-row space also provide a barrier against the spread of weeds.

Strip-till cultivation is mostly used to reduce erosion at fields that are at risk. Soil erosion is the most frequent problem when growing wide-row crops. Soil protection is achieved by leaving crop residue in the unprocessed inter-row space.

The STRIP-MASTER EN has a robust frame where the individual working units are mounted. Each cultivation unit is mounted to the frame with a clip. The cultivation unit includes a parallelogram that ensures perfect terrain contouring and maintaining the set working depth.

The loosening legs of the STRIP-MASTER EN cultivator are hydraulically protected to provide higher durability and easy operation. The release force is set to 750 kg and the legs can deflect by 26 cm in the case of contact with an obstacle.

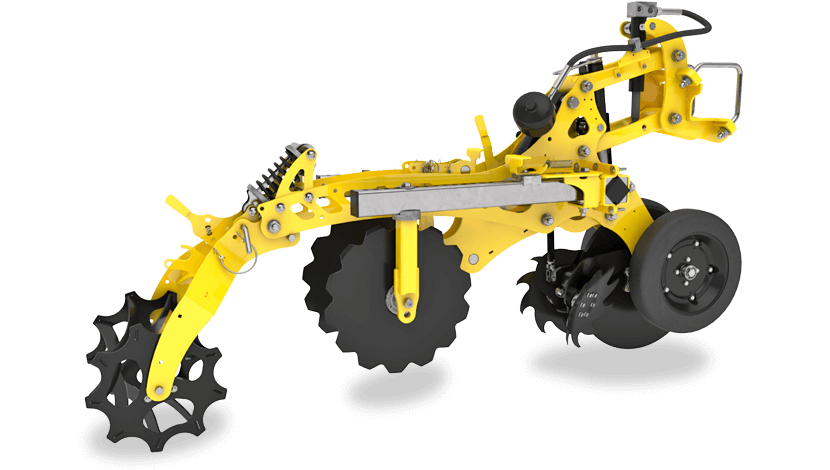

The working unit of the STRIP-MASTER EN cultivator consists of a cutting disc, a cleaning disc, a loosening leg, a guide disc and a rear roller. The individual working parts can be easily adjusted to the specific farming conditions and customer’s requirements.

The STRIP-MASTER EN cultivator is suitable for the preparation of strips for wide-row crops, such as corn, soya, sunflower or oilseed rape. The individual cultivation units are easily adjustable on the frame to an inter-row spacing of 45-80 centimetres, so the machine can be modified according to the crop.

The strip-till cultivator can be used for strip preparation without any prior soil cultivation, for example, directly in the catch crop or in fields with larger quantities of crop residue. When the STRIP-MASTER EN cultivator is equipped with a short inter-row spacing of 45/50 centimetres, the individual cultivation units are offset to ensure trouble-free work without clogging.

The FERTI-BOX FB_F front mounted hopper is designed for supply fertilisation directly in the soil profile and has a capacity of 1,900-2,200 litres. Fertiliser is pneumatically distributed from the front hopper to the distribution head mounted on the cultivator.

The FERTI-CART FC has a capacity of 3,500 litres. The large inclination of the hopper also allows to apply lower-quality fertilisers. The STRIP-MASTER EN cultivator is easily connected using the three-point hitch.

The COMBO SYSTEM CS is double-chamber air-cart which has a total capacity of 5,000 litres. The strip-till cultivator is connected in the three-point hitch of the COMBO SYSTEM CS. The double-chamber hopper design enables applying two different types of fertiliser in one pass.

The STRIP-MASTER EN cultivator can also be connected with a self-propelled or trailed applicator for organic fertilisers – slurry or digestate.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the strip-till cultivator.

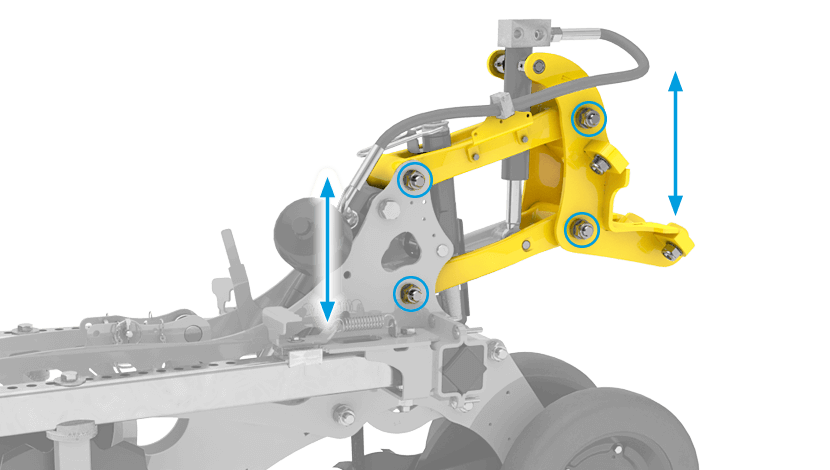

Easy connection to the three-point hitch of the tractor. Category III/IV hitch.

Maintain the set working depth and perfectly contour the terrain.

Distributes applied organic or mineral fertilisers evenly in the distribution pipes leading to the individual cultivation units.

Cuts crop residue and disturbs the hardened topsoil.

Removes crop residue from the strip to prevent clogging of seed drills during the follow-up operation.

Processes soil up to a depth of 35 centimetres.

The discs surround the legs and keep the processed soil in strips.

The rear roller crumbles large soil parts and provides reverse soil consolidation to prevent moisture evaporation.

Easy connection to the three-point hitch of the tractor. Category III/IV hitch.

Maintain the set working depth and perfectly contour the terrain.

Distributes applied organic or mineral fertilisers evenly in the distribution pipes leading to the individual cultivation units.

Cuts crop residue and disturbs the hardened topsoil.

Removes crop residue from the strip to prevent clogging of seed drills during the follow-up operation.

Processes soil up to a depth of 35 centimetres.

The discs surround the legs and keep the processed soil in strips.

The rear roller crumbles large soil parts and provides reverse soil consolidation to prevent moisture evaporation.

“Based on the positive references from our neighbours at Agro Kunčina a.s. and on the good cooperation with BEDNAR, I decided to address the regional dealer to prepare the purchase. It has been very dry and I do not want to move soil too much, and so I decided to go with the method of strip-till cultivation in the entire corn field. I cultivate soil in a targeted manner – only where it is needed under corn, where I can precisely apply fertiliser. The nutrients will be placed in zones where the corn needs them… I consulted this procedure with several experts and I believe that I have done my best. I manage my own land and I want to provide it with proper care.”

Ing. Jaroslav Dvořák,

Farm owner, Svitavy (CZ)

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own STRIP-MASTER Strip-Till Cultivator to precisely match your needs.