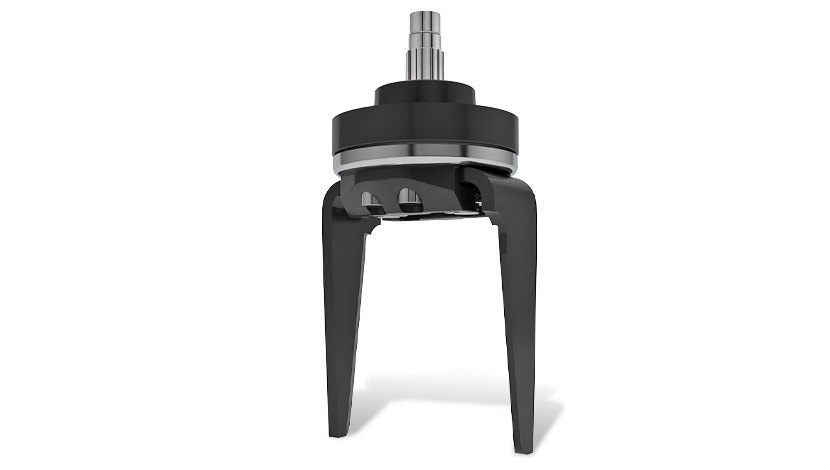

Trapeze roller

The trapezial roller is for precise and fine soil crumbling, an ideal roller for light to medium-heavy soils. The roller includes scrapers. Roller diameter 20″. Weight 904 lb/ft.

![<![CDATA[Trapézový pěch]]><![CDATA[Trapézový pěch]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/kator_trapez_roller_kn_3000.png)

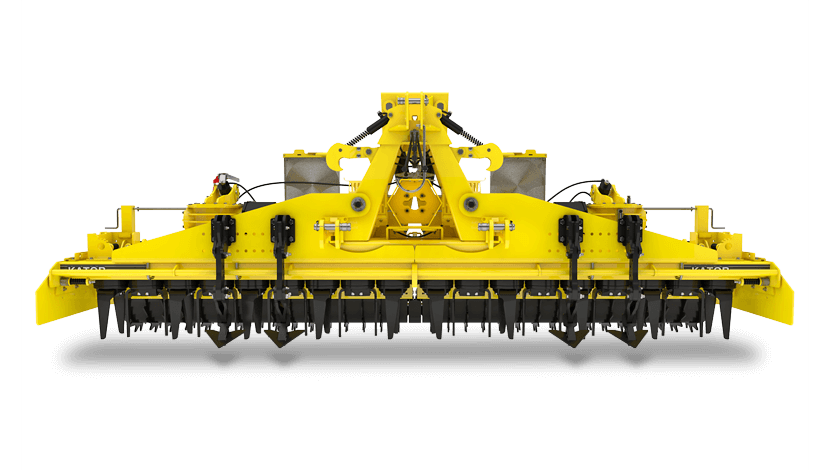

The KATOR KN is a model series of mounted power harrows with active working parts. The power harrow is especially suitable for seedbed preparation in impermeable, hard, dry and heavy soils. In one pass excellent work result and quality-prepared seedbeds are guaranteed.

10" in

9' 10"-26' 3" ft

70-430 hp

A power harrow for even tillage and quality seedbed preparation, especially in heavy, hard and dry soils.

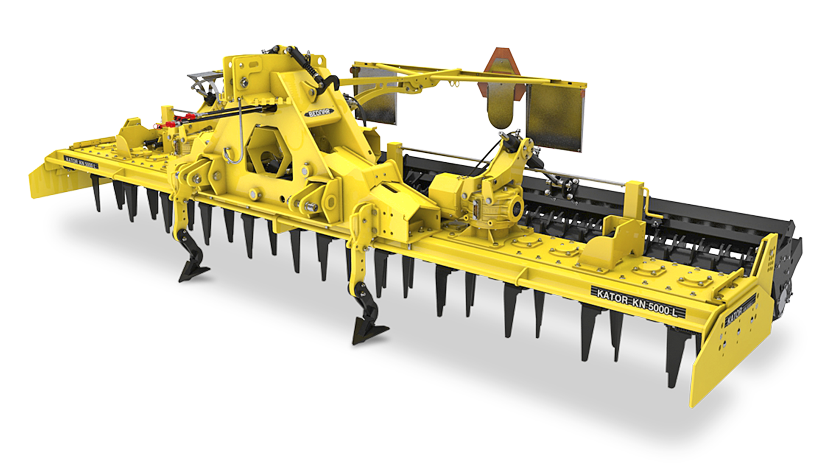

The KATOR KN_L is our first model of power harrows, available in working widths from 9′ 10″ to 16′ 5″. With a rotor spacing of only 8.9″, it offers superior clod-crumbling and precise seedbed preparation for optimal crop establishment. This tool offers the best combination of reliability, efficiency, and lightweight construction for easy use and quality seedbed preparation.

The KATOR KN represents our mid-range offering. This implement is available in working widths from 9′ 10″ to 19′ 8″ and fits with BEDNAR standards: a design focused on robustness, a high number of rotors per meter for quality seedbed preparation, and smart options to adjust the machine to customer requirements (QUICK-CHANGE system, hydraulic settings). The KATOR KN is equipped with a robust gearbox, able to withstand intense use, potato seedbed preparation, or heavy soils.

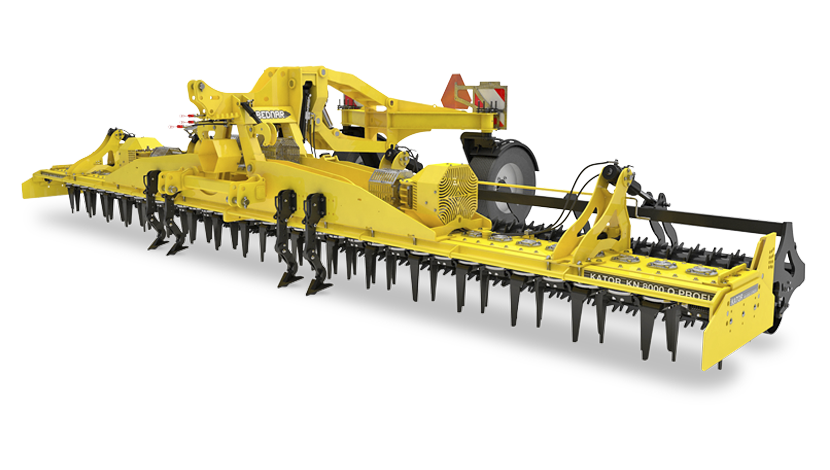

The KATOR KN_PROFI represents the top-range offering by BEDNAR. This range provides implements with working widths from 19′ 8″ to 26′ 3″ and makes no compromises: a sturdy gearbox, external oil-cooling system, highly robust frame, and quality rock protection for trouble-free use in the most intensive conditions. The 8.9″ rotor spacing offers excellent crumbling, and the wide range of options available (QUICK-CHANGE system, transport axle) delivers a professional-grade tool tailored for farmers with high standards.

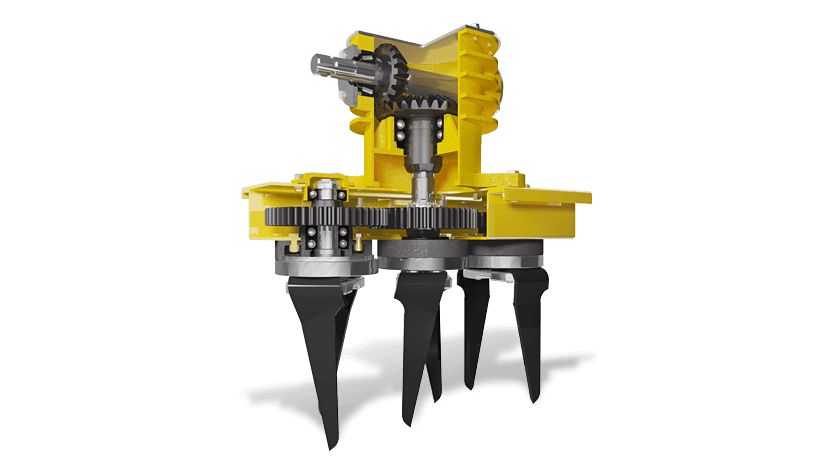

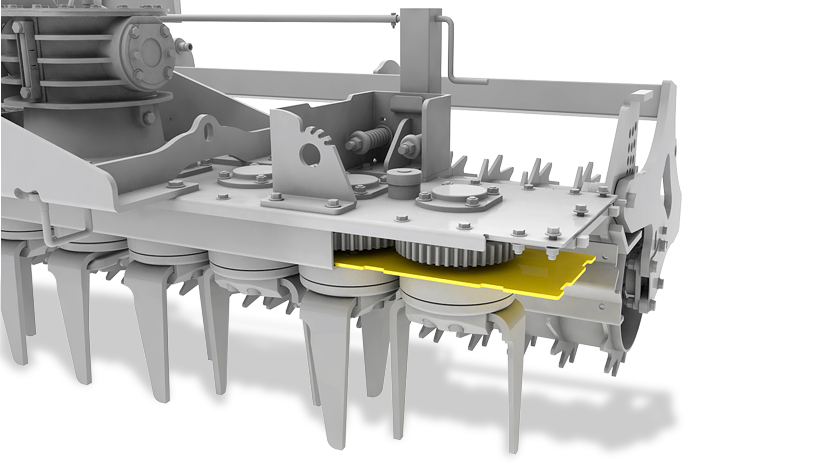

The central shaft is the main part of the power harrow and the most used component. The connection between the special solid crown with an elongated case and a reduced central shaft (3″) provides for a perfect transfer of force between the gearbox and the cascade of gearwheels.

Each rotor is equipped with three bearings (the shaft is mostly surrounded by bearings). This system provides for perfect rotor stability and protects gearwheels, shafts and gaskets from damage. No other competitor offers three bearings per rotor.

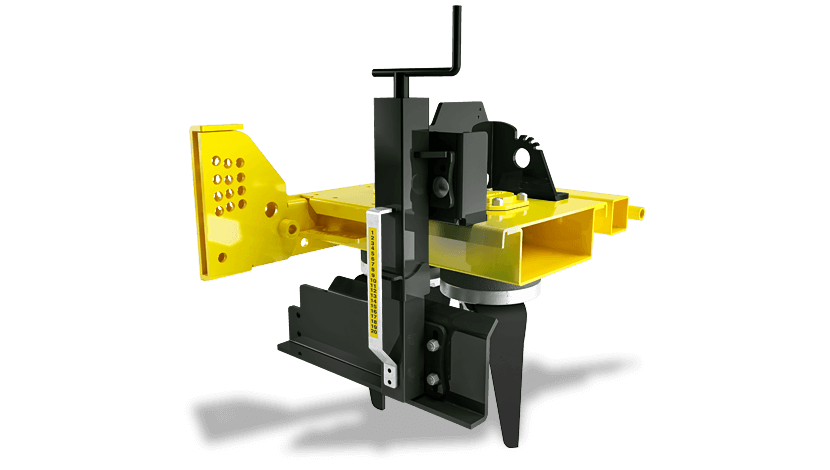

A quick and easy blade replacement. Just pull out the safety pin, remove the pin and replace the blade. It is a system designed to be used without any special tools and equipment.

*only available on KN and KN_PROFI

The special “STONE” equipment prevents stones from penetrating or sticking between the blade holder flange and the rotor. The bearing holder and cover are made from one part. The cover is screwed to the machine frame and the shaft turns inside the cover. This way, no foreign objects that could damage the gasket or bearing can enter the rotor area.

The folding arrangement of the BEDNAR KATOR power harrow offers only 8.9″ between rotors. A larger number of rotors per metre of the working width improves soil crumbling.

The rear levelling bar is very close to the rotors. This design is better for higher quality of soil levelling (a greater distance between the rotor and the rear levelling bar creates waves).

The bottom part of the main frame of the gearbox cascade of gearwheels is made of steel with a thickness of 0.5″. The main gearbox is not filled with oil but with a highly viscose grease that ensures reliable lubrication of the gearwheels. Also, the risk of oil leak into soil is eliminated in case of tub damage, such as puncture.

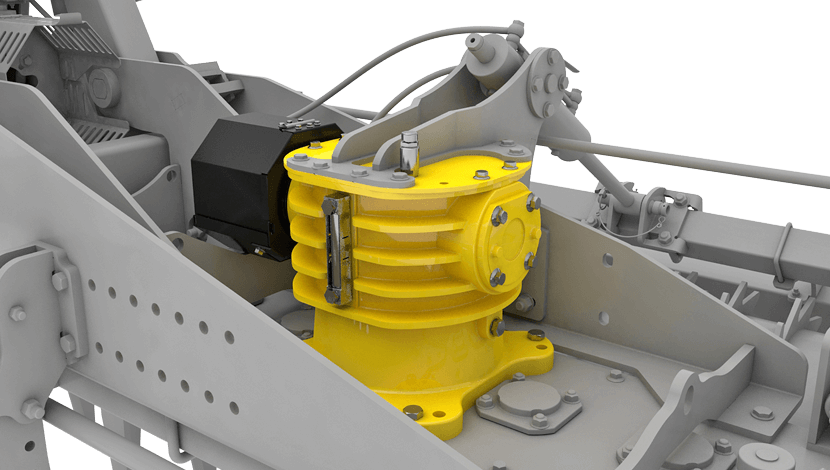

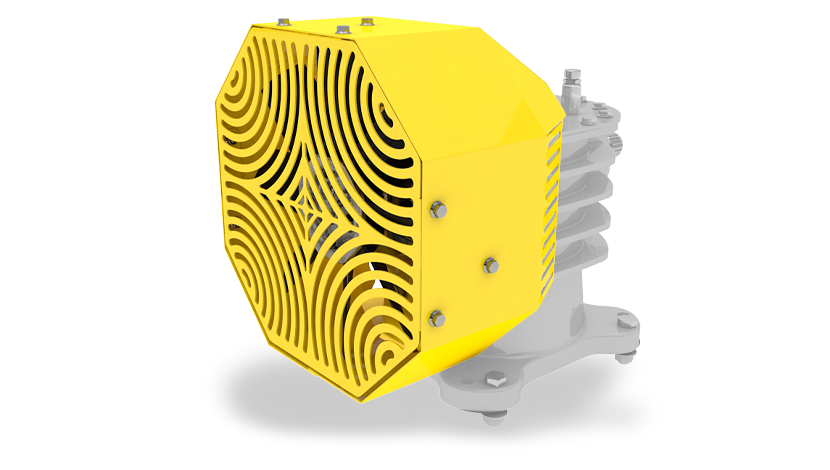

The KATOR KN 6000 model and the KN_PROFI model series can be equipped with external gearbox oil cooling for intense long-lasting operation without overheating.

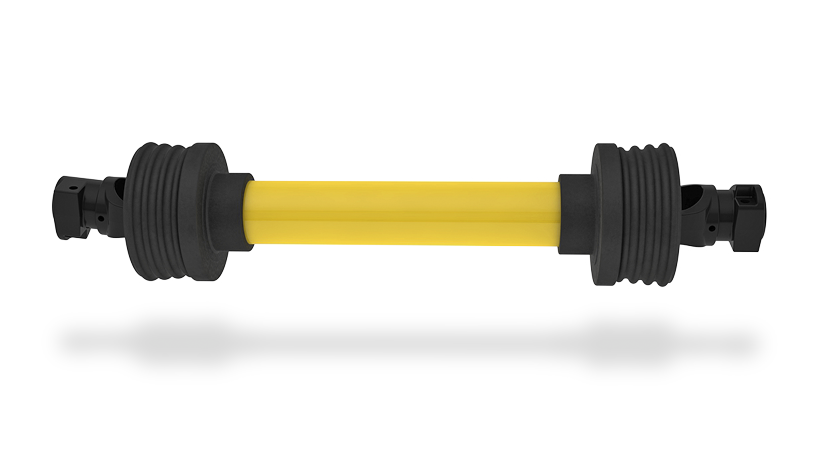

The KATOR KN power harrows have high quality P.T.O. shafts by Walterscheid in various dimensions according to the model.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the power harrow.

Easy connection to the three-point hitch of the tractor.

P.T.O. shaft connection to the pulling vehicle.

Robust gearbox for perfect power transmission.

The power harrow blades offer a system of easy blade replacement for a simple and fast exchange in the case of wear and tear or damage.

Maintains cultivated soil along the working width without the risk of side ridge formation.

Provide reverse compaction and closure of the soil profile for reduced evaporation of soil moisture.

“We started using the BEDNAR KATOR KN 23′ Q PROFI power harrow at our farm for tillage in difficult conditions in fields that are hard to cultivate. We tested what the power harrow can do and in my opinion it is a high-quality implement. Thanks to the high number of rotors per feet of working width the clod crushing is much better than in competitive power harrows. I am very pleased with the harrow and so we also purchased another BEDNAR power harrow with a working width of 26′.”

Alan Tamburini,

Farmer, Alfonsine (Italy)

We know that everyone has different requirements for the optional implememt equipment and its expected use. Therefore, you can specify your KATOR KN power harrow to precisely match your needs.