Dual caster gauge wheels

Help maintain the set working depth, contour the terrain and make headland turns.

![<![CDATA[Double front swivel support wheels]]><![CDATA[Double front swivel support wheels]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/atlas_ae_12400-profi_otocna_kola.png)

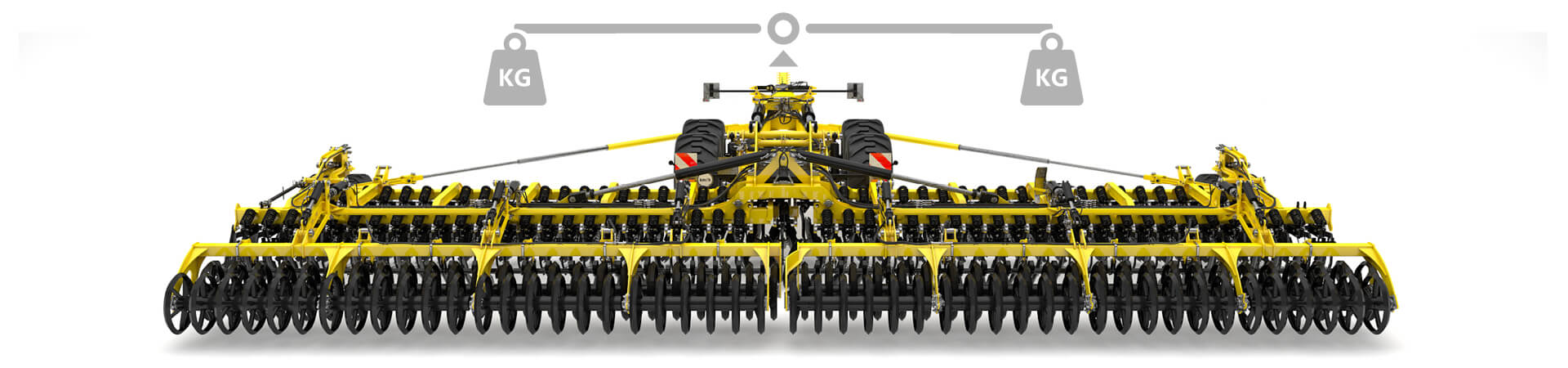

The ATLAS AE_PROFI large high speed disc is designed for processing large quantities of crop residue. Use it in fields after harvesting grain corn, to incorporate cover crop or organic fertilizers. The dual axle in front of the first blade rank evenly distributes the implement weight and thus down pressure on both side frames, which ensures that the set working depth is maintained along the entire width of the tool. The working width of 34′ 1″ / 40′ 8″ is also suitable for controlled traffic farming systems (CTF).

2.5"-6.5" in

34' 1"-40' 8" ft

450-650 hp

The ATLAS AE_PROFI model line includes robust large speed discs with properties suitable for processing large quantities of crop residue.

ATLAS AE_PROFI large high speed disc models have blade gangs arranged in the pattern of X. This innovative technical design eliminates drifting of the speed disc to the side. That allows the high speed disc to precisely follow the tractor track. The central double disc prevents the risk of ridge formation.

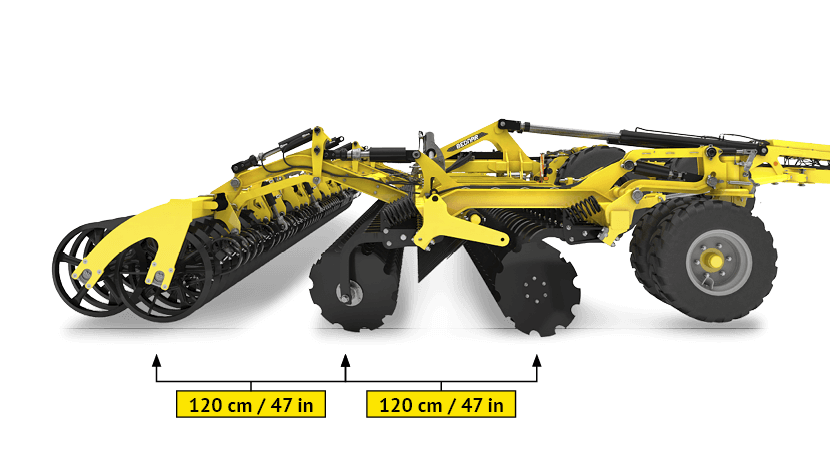

The ATLAS AE_PROFI heavy speed discs have properties that predetermines them to process large quantities of crop residue, in particular grain corn, cover crop, or organic matter. For trouble-free work and elimination of potential clogging of the implement, even when working in muddy conditions, this line offers a sufficient distance between the individual working gangs. The distance between the front and rear rank of the blade gang is 47″ and the distance of blades to the rear packer is up to 47″. The underframe clearance is about 27.5″ and it provides trouble-free throughput.

ATLAS AE_PROFI is a speed disc fully compatible with ISOBUS. The BEDNAR EASY CONTROL software provides fully automated folding and unfolding of the implement using a single button, and all working parameters are set by entering the values at the terminal. All the settings, including the working depth, can be comfortably adjusted also during work, which prevents undesirable downtime.

Maintaining the set working depth for even soil profile processing is the foundation of quality tillage. ATLAS AE_PROFI high speed disc provides the same pressure on blades along the entire machine width thanks to the axle moved forward and the concept of two folding side frames. The structural design of the implement reduces the number of hydraulic cylinders where side frame pressure could be lost. This design also reduces the number of points of lubrication, the overall wear of the machine, and it simplifies manipulation with the tool, both in the field and on the road.

The ATLAS AE_PROFI heavy large speed disc is manoeuvrable very well thanks to its design, even at headland. The machine turns using the rear rollers, the dual caster gauge wheels, and the transport axle. This design eliminates the negative load on the hitch and unloads the tractor when the implement is in the headland position.

Even with the working width of up to 40′ 8″, the ATLAS AE_PROFI large speed disc is very compact in transportation, because it does not exceed the transport width of 9′ 10″ and the height of the machine is just below 13′ 1″, even when equipped with double V-RING or U-RING rollers. Such parameters are achieved mainly thanks to the forward side frame folding, towards the drawbar.

The CTF (controlled traffic farming) system eliminates soil compaction and optimises the passes of the individual sets. When working, the individual sets travel across the field in the given grid of the working width (20′, 40′, 60′, 80′ etc.), which prevents the formation of uneven compaction in the field as well as in the tracks that can be easily tilled.

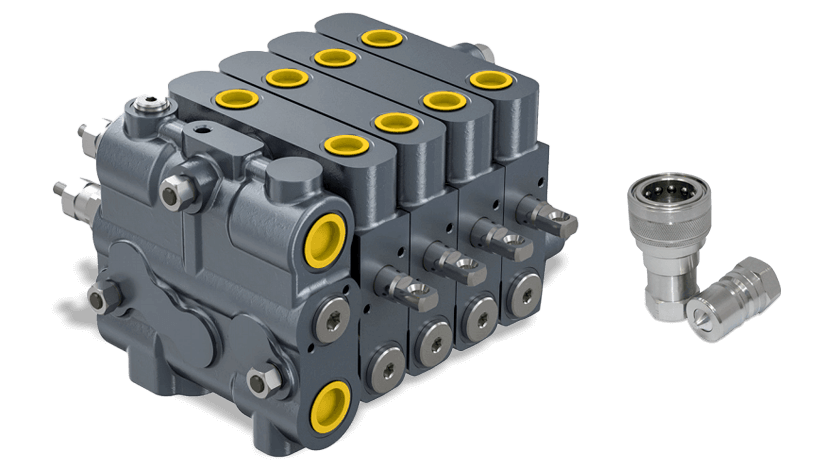

The ATLAS AE_PROFI large speed disc is connected to the tractor’s LOAD-SENSING hydraulic output using only three hoses. The adjustable pump then only delivers as much oil under pressure as needed by the specific task of the individual function; it is all completely automated. The system efficiently uses the pressure in the hydraulics and controls the individual functions that required high output.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working tools of the high speed disc.

Provide excellent terrain contouring and maintain the set working depth along the entire width of the implement.

Blade gang with notched or aggressive discs, with a diameter of 24″×0.24″ and auto-reset protection of each blade arm.

Provides ideal distribution of the implement weight and contributes to precise adherence to the set working depth thanks to the identical pressure on the blade gangs.

Facilitates crumbling and slowing down the flow of matter in front of the rear packers to prevent the risk of clogging.

The wide range of rear packers make it possible to adjust the implement to any conditions. The packers crumbles clods and consolidate soil to prevent its drying.

“It took us a long time to choose the high speed disc. We made our decision after we tested the BEDNAR tool. ATLAS AE_PROFI provides precisely the work we need and that was essential in making the decision.”

Horvath Szabolcs, Machinery Technician

GAMOTA, Hurbanovo Production Cooperative, Slovakia

We know that everyone has different requirements for the optional implement equipment and its expected use. Therefore, you can specify your own ATLAS AE_PROFI speed disc to precisely match your needs.

Help maintain the set working depth, contour the terrain and make headland turns.

![<![CDATA[Double front swivel support wheels]]><![CDATA[Double front swivel support wheels]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/atlas_ae_12400-profi_otocna_kola.png)