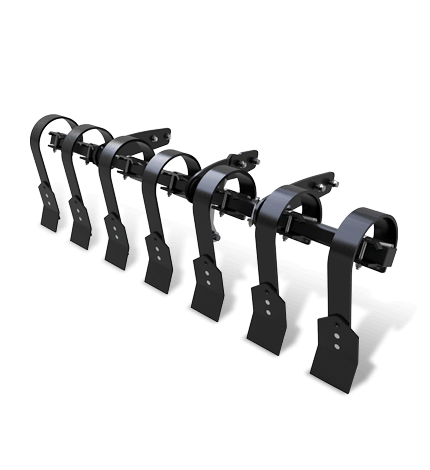

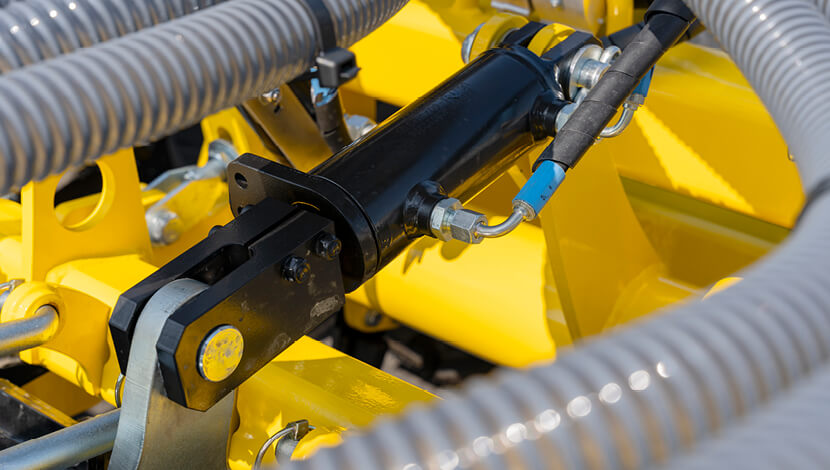

Crushbar levelling bar

The hydraulically controlled levelling bar is suitable for levelling unevenness and surface after the disc section.

The OMEGA OO_L pneumatic seed drill is a versatile machine suitable for crop establishment in both conventional and minimum tillage technologies, but it can also be useful for direct drilling into mulch, or grass over-seeding. The OMEGA OO_L seed drill offers a disc section, and a wide range of optional equipment, including two row spacing options of 12.5 or 16.7 cm. The arrangement of the individual working tools provides an unparalleled soil preparation before seeding in combination with precise seed placement.

3-9 m

120-500 hp

2 800-4 000 l

A versatile seed drill that can be equipped with a wide range of optional equipment, to meet the latest agronomic requirements.

France

First name: Pascal Perard

Farm name: SCEA DE VESVRES

Number of hectares: 600 ha

Year of purchase: 2023

„This seed drill, equipped with large tyre packer, consolidates the soil well, and the offset wheel system is really well thought-out. It’s a seed drill that’s very well thought out for everything. That’s why we chose it and we don’t regret it at all..“

Join us in our series to meet BEDNAR OMEGA seed drill users who have bet on the quality of these versatile seed drills.

Find out more

The OMEGA OO_L versatile seed drill can be also used for direct drilling into a ploughed field without any prior tillage. The effective combination of the front levelling bar, the tyre packer and the PROFI coulter section creates and even seedbed. Quality surface levelling, perfect clod crumbling, precise seed placement and reverse consolidation in one pass!

OMEGA OO_L is a suitable seed drill for establishing crops in no-till systems. The disc section equipped with specially shaped aggressive discs provides a perfect cutting and mixing effect; the specially shaped discs also improve soil penetration. The OMEGA OO_L seed drill can be thus easily used for establishing catch crops in a stubble after the harvest, or seeding winter crops without any prior tillage.

New agronomic trends demand new crop establishment methods. The OMEGA OO_L seed drill can be used for crops establishment, such as winter crops, in the catch crop stands. The front tyre packer rolls over the catch crop, the disc and coulter section cuts it, and the seeds are placed at the required depth thanks to the high down pressure on the drill coulters.

The high versatility of the OMEGA OO_L seed drill makes it possible to use the machine for grass over-seeding during the year. We recommend performing this operation without using the front disc section, but using the TURBO coulters behind the disc section that creates a groove in the line of the seeding coulter and facilitates its penetration into soil. The grass vegetation remains undisturbed.

No other seed drill on the market offers the option to combine the front Crushbar levelling bar with the tyre packer. Perfect soil levelling before the drill coulters is an important part of seeding. The Crushbar breaks the rough furrow and levels off any unevenness, the tyre packer evenly consolidates the soil along the entire width of the machine, and contributes to maintaining its stability at high working speed.

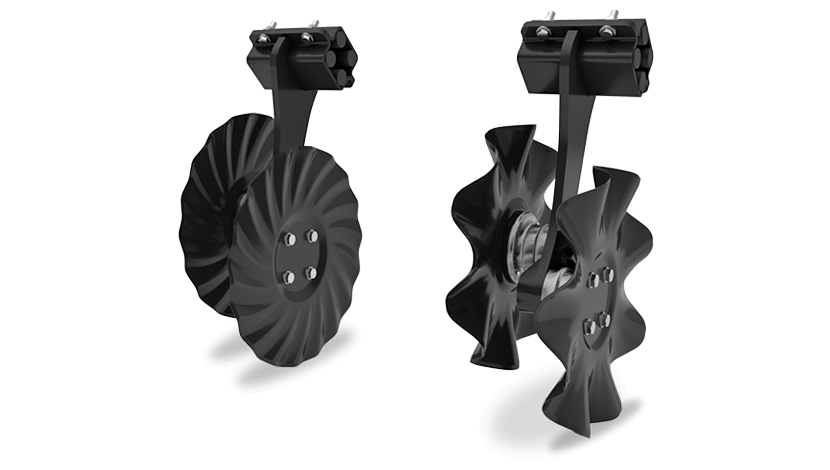

The working section behind the disc section is definitely what makes BEDNAR machines distinct. It can be equipped with the popular PROFI coulters for better tillage, or TURBO coulters for creating a groove for drill coulters in the case of direct drilling.

It is possible to install the Crushbar levelling bar in front of the disc section, or to combine the Crushbar with the front tyre packer Frontpack. The working angle of the levelling bar is controlled hydraulically from the tractor cabin.

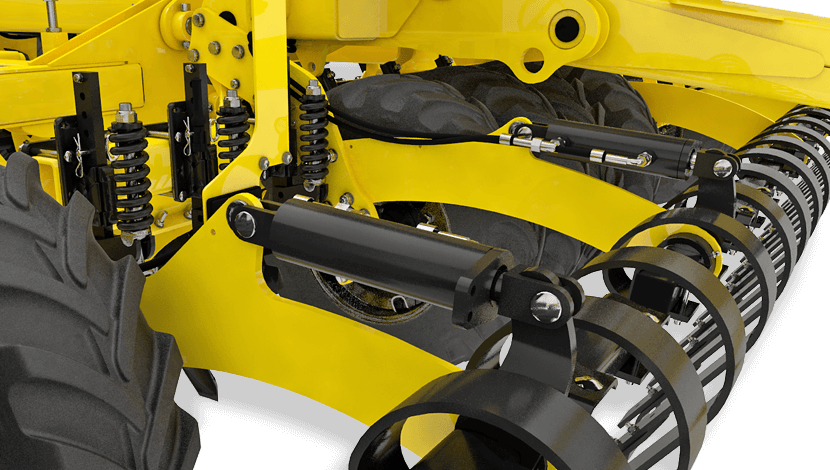

There are two ways to set the working depth of the disc section. It can be set hydraulically from the tractor cabin, or mechanically.

The seed drill can be equipped with a whole range of optional equipment behind the disc section. The section is set hydraulically from the comfort of the tractor cabin.

The drill coulter pressure can be set at up to 130 kg according to the conditions. The pressure is set hydraulically or mechanically.

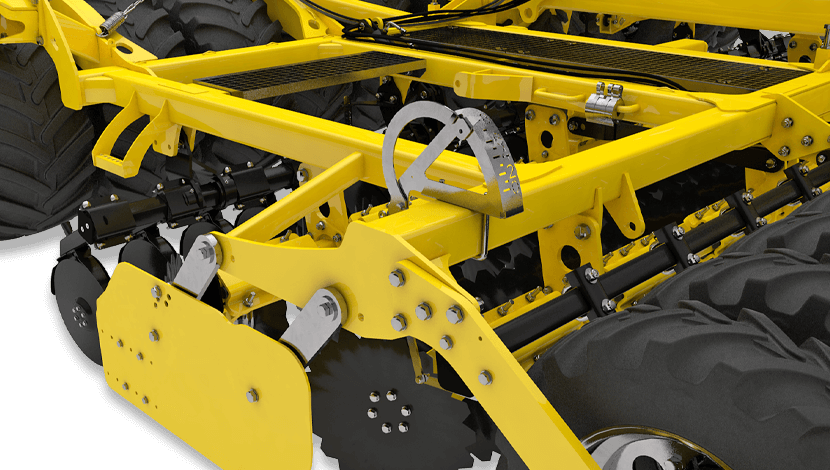

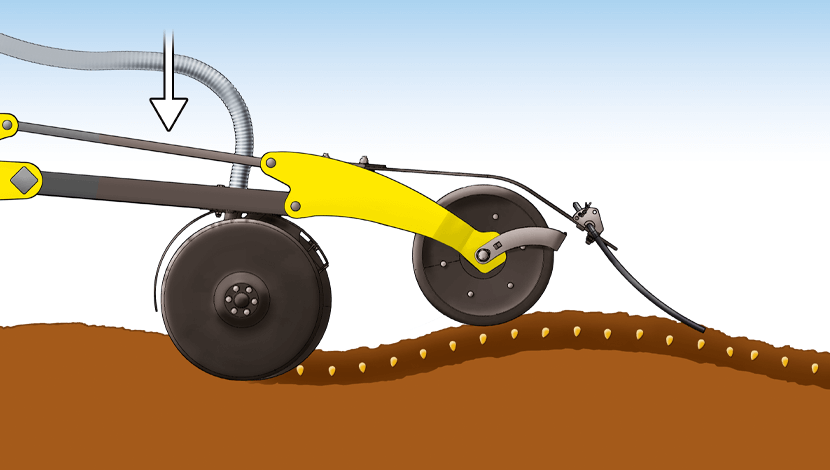

The double-disc seeding coulter can place seeds or fertiliser at a depth of up to 8 cm. The working depth can be regulated hydraulically or mechanically.

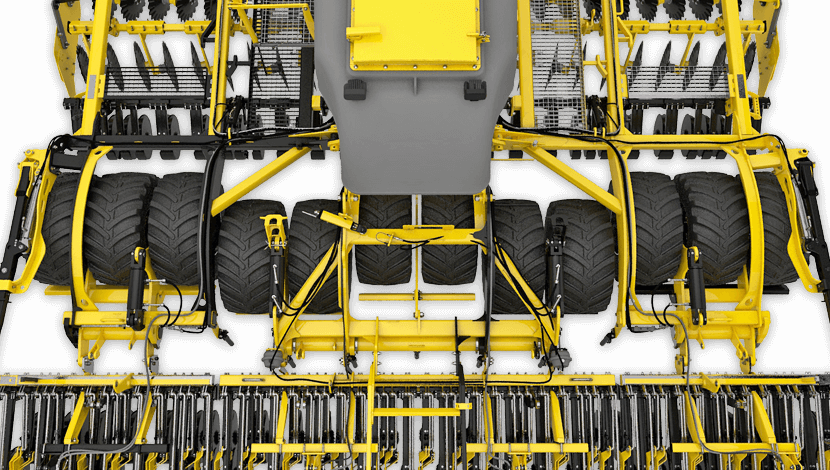

The OMEGA OO_L seed drills have disc sections arranged in X pattern. This innovative technical design eliminates drifting of the machine to the side. That offers a precise following of tractor tracks.

The large and wide wheels mounted in an offset system under the hopper perfectly consolidate and level the soil. The offset arrangement of the tyre packer increases soil and crop residue throughput, which reduces rolling resistance and thus the towing power demand. The wheels can be easily replaced in the case of a puncture! The wheels are mounted independently and the seed drill turns at headland using the packer, except for the two central wheels, which prevents the undesirable formation of tracks.

The double-disc seeding coulters are attached to the seed bar frame with a parallel linkage. That allows the individual drill coulters to perfectly contour the terrain and place seeds evenly at a constant depth level along the entire working width, resulting in an even stand.

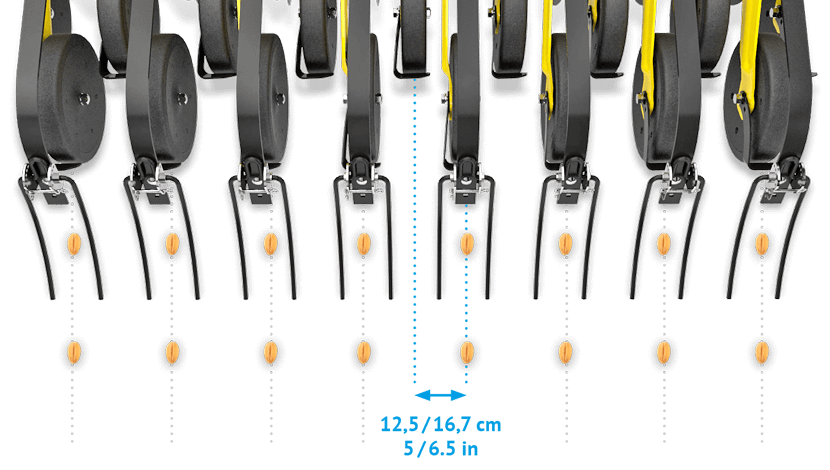

The OMEGA OO_L seed drill can be equipped, while in production, with drill coulters with an row spacing of 12.5 cm suitable for cropping systems with a high ratio of cereals in the crop rotation. The row spacing of 16.7 cm is suitable for seeding with large quantities of crop residues on the surface.

The double-disc seeding coulter with an offset disc cuts crop residues and creates a clean and perfect seedbed for even seed placement. There is either a standard, or carbide scraper between the two discs. The seeds are then covered with fine soil and pressed down into the soil by the depth wheel. The depth wheel is available in two sizes: 330×50 mm and 330×65 mm.

The OMEGA OO_L seed drill is equipped with two distribution heads, which makes it possible to deactivate a half of the working width of the machine – mechanically, or electronically from the comfort of the tractor cabin. It prevents undesirable excessive seeding.

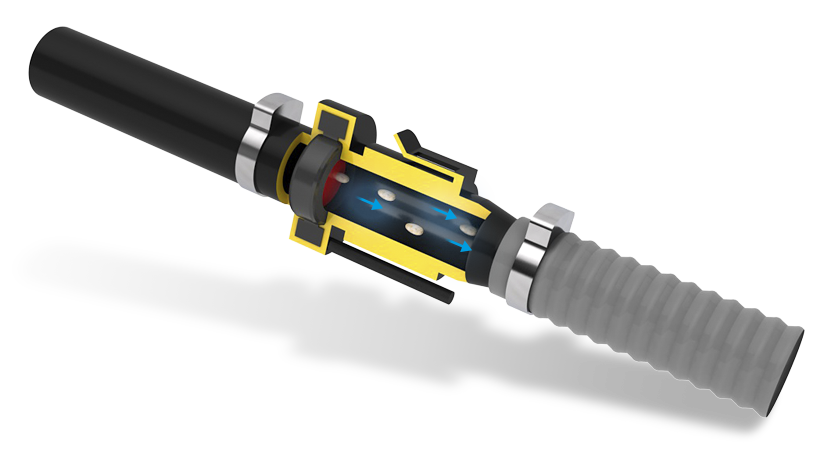

The seed drill can be equipped with flow sensors on request. The device ensures that if a drill coulter gets clogged, the information is displayed on the screen. That guarantees maximum seeding precision.

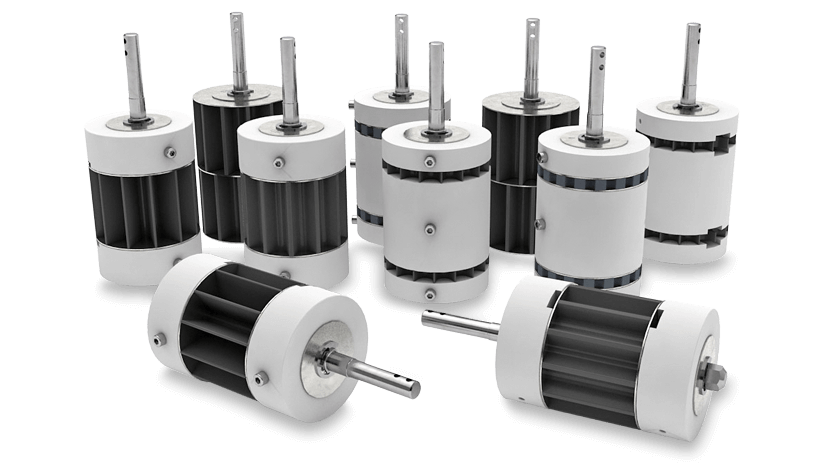

The metering unit is made of stainless steel and driven by an electric motor. It is equipped with a radar sensor connected to the ISOBUS communication channel. The seed metering unit provides high precision seeds batching from 0.6 to 350 kg/ha.

The fast and comfortable filling of the OMEGA seed drill hopper is ensured by an easily accessible platform and steps. To fill the hopper, the steel lid swings by 90°. The hopper filling level is indicated by two sensors. One is installed higher and its angle is adjustable, the other one is installed in the lower third of the hopper.

We have developed the OMEGA seed drill also with an easy and comfortable operation in mind. The seed calibration at the rear of the machine is also easy – a calibration bag is simply placed below the pipe. You do not need to climb the disc section and perform complicated calibration under the hopper. The outlet also makes it easy to empty the hopper contents.

Emphasis was placed on easy control when developing the OMEGA seed drill. The seed drill can be connected to the tractor via the ISOBUS technology, or it can be controlled using a BEDNAR ISOBUS display. A series of control displays with basic or advanced control functions are available.

BEDNAR developers designed an application for mobile phones that provides easy and simple calibration of the seed drill from your mobile phone. The mobile application includes a guide that helps with the right selection of the seeding roller based on the type of seeds/fertiliser, working speed and seeding amount.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the versatile seed drill.

The hydraulic drawbar contributes to perfect terrain contouring.

The levelling bar is used for levelling coarse unevenness. The tyre packer stabilises the seed drill during work and improves terrain contouring.

The disc section, arranged in the pattern of X, with either notched or aggressive discs with a diameter of 460 × 5 mm, ideally cuts and mixes crop residues with soil.

The specially shaped PROFI coulters offer an excellent crumbling effect. They are suitable for heavier soils.

The offset arrangement of tyre packer provides trouble-free clearance, even in wet conditions. The packer with wide wheels levels off and consolidates soil before the drill coulters.

They spread ridges created between the individual wheels of the tyre packer.

Formed by double-disc seeding coulters mounted via parallel linkage for perfect terrain contouring. Optional row spacing of 12.5 or 16.7 cm are available.

Comfortable calibration of the seed metering unit and easy emptying of seeds from the hopper.

The pressurised hopper enables seeding large amounts and improves the precision of seeding.

The hydraulic drawbar contributes to perfect terrain contouring.

The disc section, arranged in the shape of X, with either notched or aggressive discs with a diameter of 460 × 5 mm, ideally cuts and mixes crop residues with soil.

The specially shaped PROFI coulters offer an excellent crumbling effect. They are suitable for heavier soils.

The offset arrangement of tyre packer provides trouble-free clearance, even in wet conditions. The packer with wide wheels levels off and consolidates soil before the drill coulters.

They spread ridges created between the individual wheels of the tyre packer.

Formed by double-disc drill coulters mounted on a parallel linkage for perfect terrain contouring. Optional row spacing of 12.5 or 16.7 cm are available.

Comfortable calibration of the seed metering unit and easy emptying of seeds from the hopper.

The pressurised hopper enables seeding large amounts and improves the precision of seeding.

“We are now starting to use the catch crop. It was one of the main reasons for purchasing the OMEGA OO 8000 L seed drill, equipped with the ALFA DRILL 400 seeder. Another reason was the large, eight-metre width of the machine with the Frontpack that evenly distributes the weight of the machine and soil processing working sections. With our machine configuration, we can seed directly into a ploughed field, or into a perfectly prepared seedbed. And we like that, just like being able to seed at least 80 hectares per day.”

Václav Richter,

Agronomist, Zemědělské a obchodní družstvo Žichlínek, Žichlínek (district of Ústí nad Orlicí, CZ)

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your OMEGA OO_L versatile seed drill to precisely match your needs.