Double front caster wheels

Help maintain the set working depth, contour the terrain, and turn the machine at headlands.

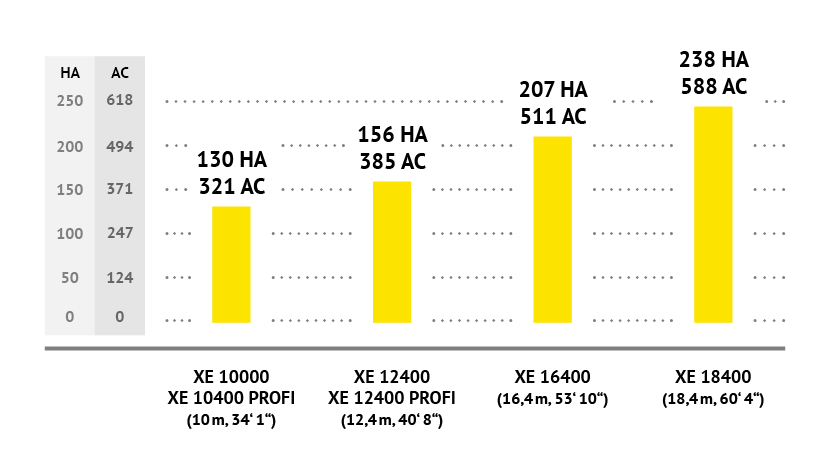

Maximum daily output, compact design, and easy intuitive operation are the hallmarks of the SWIFTERDISC XE_PROFI wide working width compact disc harrow. Two models with a working width of 10.4 to 12.4 meters and a design working speed up to 18 km/h enable high working speeds, resulting in cost savings and high daily output.

2-14 cm

10,4-12,4 m

350-500 hp

The XE_PROFI wide working width compact disc harrow with intuitive controls and a range of technical advantages that improve the quality of work.

Stubble cultivation is one of the most important operations. According to proper agrotechnical procedures, it should be performed as soon as possible after harvest. For this operation, the SWIFTERDISC XE_PROFI can be equipped with notched disc or aggressive discs with a diameter of 520 × 5 / 560 × 5 mm, which ensure excellent cutting, soil mixing, and incorporation of plant residue. The rear packers then consolidate and close the processed soil profile for even weed and volunteer emergence.

The optimal diameter combined with high working speed allows high circumferential speed of the discs to be achieved, ensuring excellent crumbling and mixing effect of the disc section. The tape shear in front of the rear packers contributes to the final leveling of the surface together with the excellent crumbling effect of the rear packers.

SWIFTERDISC XE_PROFI is a fully ISOBUS-compatible implement. The machine can be controlled using any ISOBUS-compatible terminal. The proprietary BEDNAR EASY CONTROL software allows for fully automated folding and unfolding of the machine with a single button, and all working parameters are set directly on the terminal. All settings, including working depth adjustment, can be conveniently adjusted even during operation, thus avoiding unwanted downtime.

SWIFTERDISC XE_PROFI models have disc sections arranged in an “X” pattern. This innovative technical solution eliminates sideways movement of the machine, known as drifting. As a result, the compact disc harrow precisely follows the tractor’s line. The center disc reduces the risk of clods forming.

The basis for high-quality tillage is maintaining the set working depth for uniform tillage of the soil profile. SWIFTERDISC XE_PROFI compact disc harrows maintain equal disc downforce across the entire working width of the machine, even at the edges of the harrow, thanks to the forward-mounted axle and the design of two folding side frames. The machine’s design reduces the number of hydraulic cylinders where pressure loss to the side frames could occur. This solution also contributes to a low number of lubrication points, reduces overall machine wear, and simplifies machine handling both in the field and during transport.

Even with a working width of up to 12.4 meters, the SWIFTERDISC XE_PROFI wide working width compact disc harrow is very compact during transport, as it does not exceed a transport width of 3 metres and a height of under 4 metres. This is mainly due to the side frames folding forward onto the drawbar.

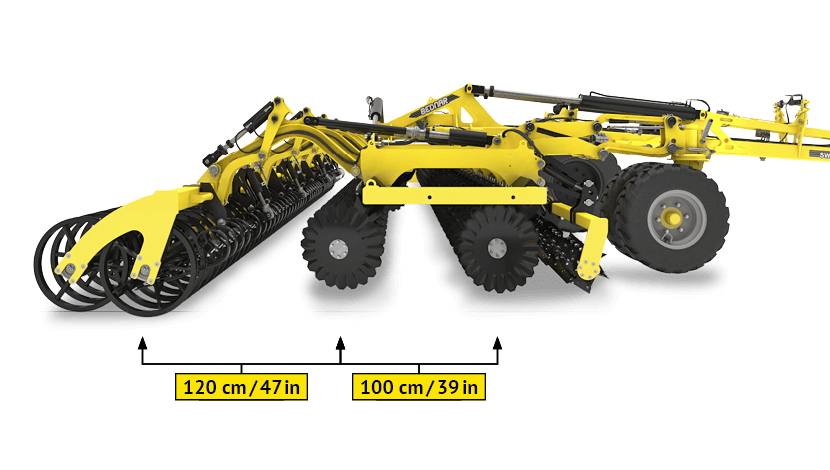

When stubble cultivation or incorporating large amounts of crop residues, the machine can often become clogged due to low throughput, or the working speed may be limited to prevent the formation of waves. SWIFTERDISC XE_PROFI compact disc harrows offer the largest distance between the front and rear rows of the disc section in this class of compact disc harrows, 100 centimetres, and the distance between the discs and the rear axle of the packer is up to 120 centimetres. The frame’s ground clearance of 56 centimetres allows for the incorporation of even large amounts of organic matter or manure.

The SWIFTERDISC XE_PROFI wide working width compact disc harrow can be equipped with the BEDNAR ALFA DRILL seeder for sowing catch crops and small-seeded plants during stubble cultivation in a single pass. This saves time and fuel. The seeder capacity 800 liters.

The CTF (Controlled Traffic Farming) system is used to eliminate soil compaction and optimize the movement of individual machines. When performing work operations, individual machines move across the land in a given working width grid (6, 12, 18, 24 m, etc.), which prevents uneven consolidation across the entire land and instead creates track lines that are then easily subsoiled.

The SWIFTERDISC XE_PROFI wide working width compact disc harrow is very easy to maneuver at headlands. The machine turns on the rear packers and front support wheels at headlands, only the disc working section is dug in without the need to lift the entire frame. This solution eliminates negative load on the hitch and lightens the tractor when the machine is at the headlands.

The SWIFTERDISC XE_PROFI wide working width compact disc harrow is connected to the tractor’s load-sensing hydraulic circuit using only three hoses. The adjustable pump automatically supplies only the amount of oil and pressure required for each function. The system can effectively utilize the pressure in the hydraulics and control individual functions where high performance is required.

SWIFTERDISC wide working width disc harrows are designed for coupling with the most powerful tractors on the market. Thanks to their sophisticated design and high working speed, these harrows offer maximum daily performance.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise overview of the main working parts of the compact disc harrow.

Cuts crop residue, namely the stalks of sunflower, corn or oilseed rape, and facilitates their incorporation and mixing with soil. The optimal size of crop residue accelerates decomposition and reduces the need for nitrogen.

Provides ideal distribution of the machine weight and contributes to precise adherence to the set working depth thanks to the identical downforce on the disc section.

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine. The harrow travels on the front caster wheels and the rear rollers when turning at headland.

Disc section with notched or aggressive discs, with a diameter of 520 × 5/ 560 × 5 mm, and high throughput thanks to the Twin-Disc system.

Provides safe turning at headland and enables the forward side frame folding.

The wide range of rear packers make it possible to adjust the machine to any conditions. The packers help close the surface and reduce evaporation of soil moisture.

“The rented machine impressed us with its high-quality performance under all conditions. Thanks to its weight and disc geometry, the stubble harrow is able to maintain the required working depth and incorporate crop residues effectively. Another reason for purchasing a BEDNAR machine was the requirement for 560 mm diameter discs, a levelling bar, and rear U-RING packers for consolidation. The BEDNAR machine met all requirements. Among other things, we also required a seeder ALFA for establishing catch crops. In this category, BEDNAR again offers a factory solution that its competitors cannot match.”

Václav Liška, Service Manager, Janovský Agro

Týn nad Vltavou (Czech Republic)

We know that everyone has different requirements for machine equipment and its intended use. That is why we allow you to specify your SWIFTERDISC XE_PROFI disc harrow exactly as you require.