WHAT DO THE FARMERS HAVE TO SAY?

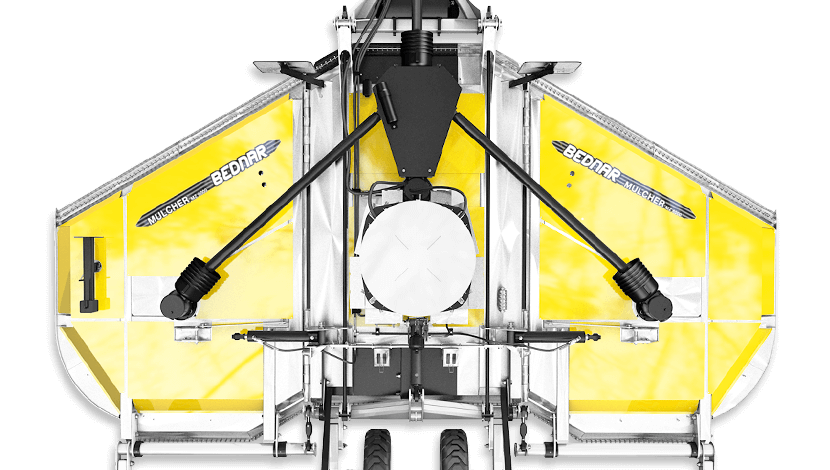

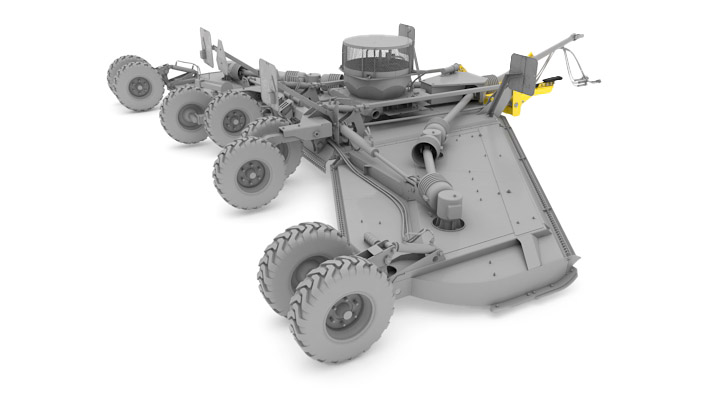

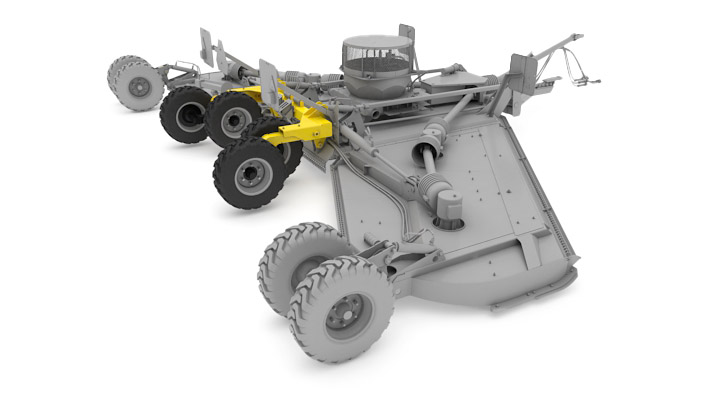

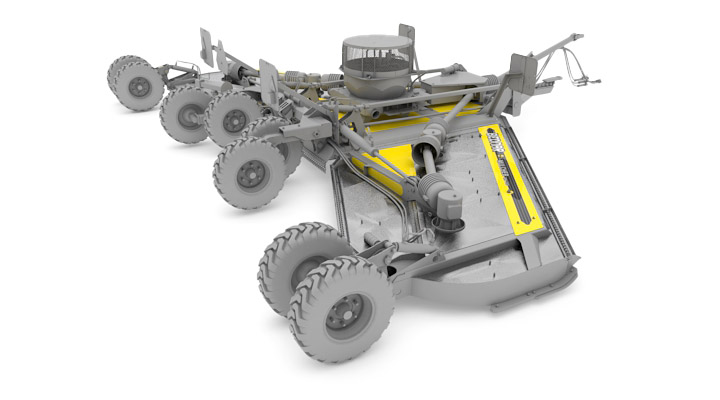

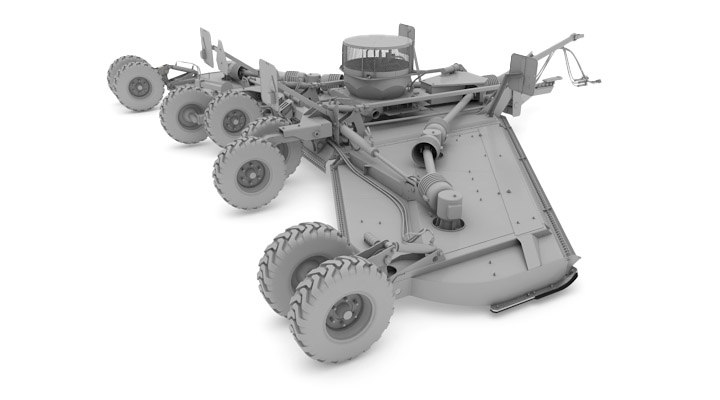

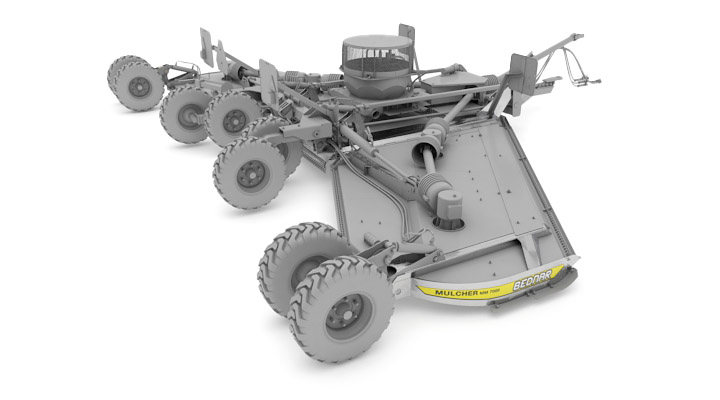

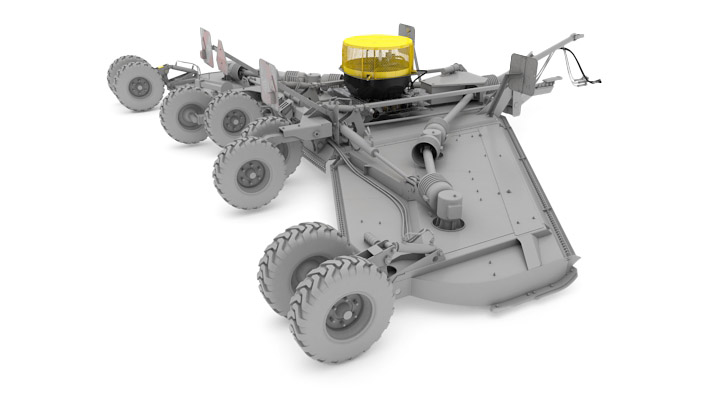

“I’ve been using BEDNAR rotary cutters since I started doing farming in this area. The first model I owned was a MULCHER MZ 15′, then a MZ 20′ and the latest addition is the largest MM 23′ model. I like the robust configuration, the quality equipment that includes the front counter blades, armouring or the special rubber wheel filling against puncture. I use the cutter mostly for cutting permanent grassland; I process about 4940 acres every year.”

Adam Kysel, Contractor

Lomnice (Czech Republic)

![<![CDATA[Corn blades]]><![CDATA[Corn blades]]>](https://www.bednar.com/wp-content/uploads/nezarazene-fotky/noze_kukurice_28667489.png)

BEDNAR FMT

BEDNAR FMT

![<![CDATA[TRASH-FAN CLEANING SYSTEM]]>](https://www.bednar.com/wp-content/uploads/nezarazene-fotky/trash_fan_00733316.png)

![<![CDATA[Grass blades]]><![CDATA[Grass blades]]>](https://www.bednar.com/wp-content/uploads/nezarazene-fotky/travni_noze_28924410.png)