Dual gauge wheels

Provide excellent terrain contouring and maintain the set working depth across the entire implement width.

ATLAS AO_PROFI is in the category of heavy high speed discs. The robust speed disc with a short frame is designed for cutting, mixing and incorporating large quantities of trash and organic matter in the soil, even in muddy conditions. This key advantage of the ATLAS AO_PROFI speed disc is provided by the robust design, high underframe clearance, spacing of the individual blade gangs and the large disc diameter.

2.5"-6.5" in

16' 5" -23' ft

250-400 hp

The ATLAS AO_PROFI model line is a robust line of versatile high speed discs with properties suitable for processing large quantities of crop residue, as well as for primary tillage after harvesting cereals.

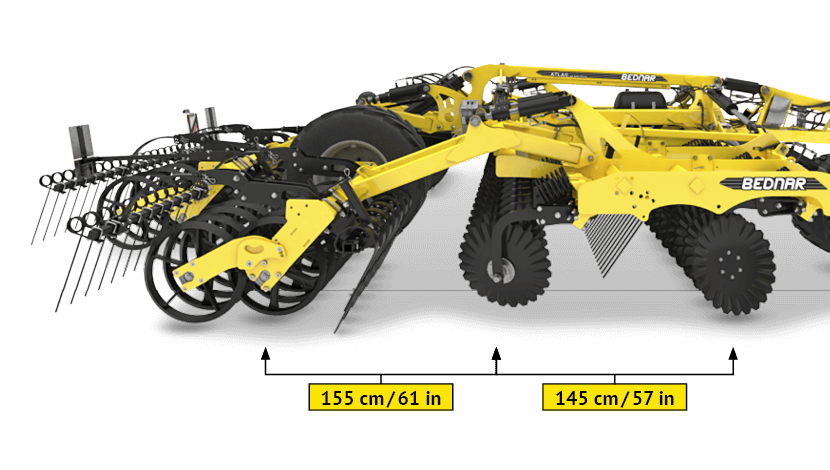

ATLAS AO_PROFI models have blade gangs arranged in the pattern of X. This innovative technical design eliminates drifting of the speed disc to the side. That allows the high speed disc to precisely follow the tractor track. The central double disc reduces the risk of ridge formation.

The two ranks layout of rear packers provides better stability at high speed than a one rank design. The integrated axle ensures even distribution of the implement weight and eliminates its bouncing. Moreover, it ensures safer transport and reduces the turning radius of the tractor with the speed disc at headland.

The ATLAS AO_PROFI high speed disc is a heavy version of these speed discs. Its robustness makes the speed disc heavy and allows it to create an even down pressure on the blade working gangs that can penetrate soil without problems even during drought. The implement robustness also contributes to excellent incorporation of large quantities of matter.

ATLAS AO_PROFI heavy high speed discs have properties that predetermine the tool to be used for processing large quantities of trash, cover crop and other organic matter (slurry, manure). For trouble-free work and elimination of potential clogging of the implement, even when working in muddy conditions, this model line offers a sufficient distance between the individual working gangs. The distance between the front and rear rank of the blade gang is more than 57″ and the distance of blades to the rear packer is up to 61″. The underframe clearance is about 27.5″ and it provides trouble-free throughput.

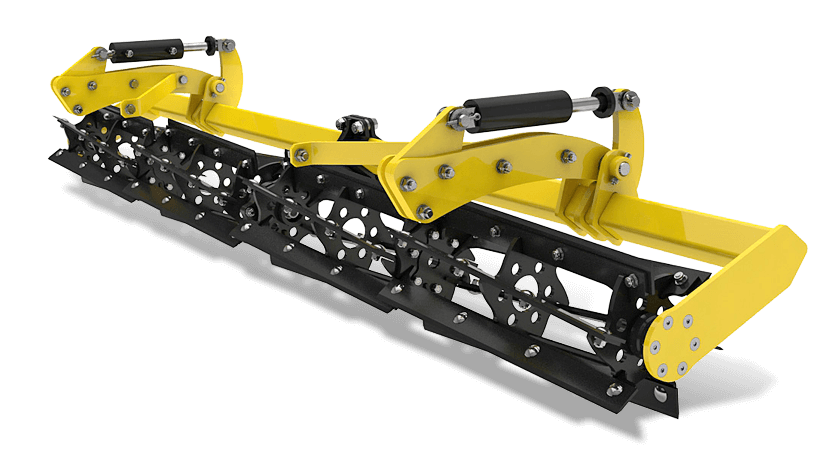

The ATLAS AO_PROFI speed disc can be equipped with the Trash Cutter cutting roller in the front, an ideal choice for cutting crop residue and hard stalks. Such cut crop residue decomposes better in soil and facilitates subsequent soil cultivation, preventing machine clogging.

The basic model of the ATLAS AO_PROFI high speed disc already includes easy setting of working depth without using spacers of hydraulic cylinders. The working depth is set using the hydraulics on the rear rollers and the gauge wheels.

ATLAS AO_PROFI can be equipped with electrical-hydraulic implement control. BEDNAR EASY CONTROL is the Company’s own software that provides a fully automated control of the speed disc and allows setting the working depth from the cabin in an easy and simple way, using the tractor’s display, or by connecting an ISOBUS cable with the tractor’s display.

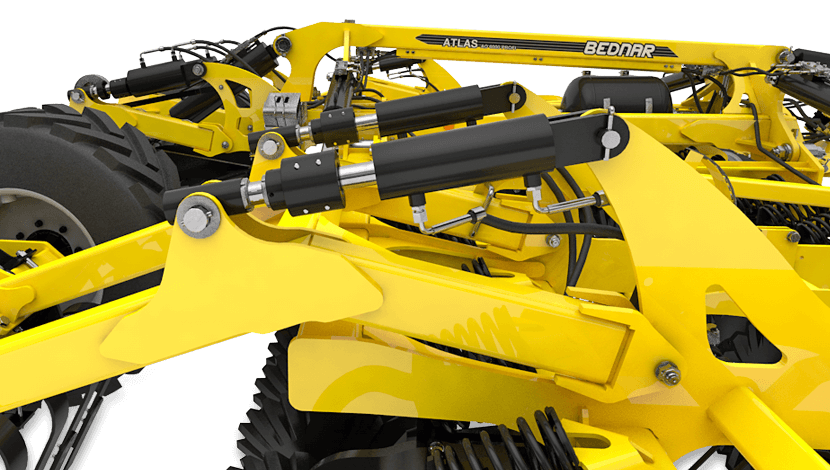

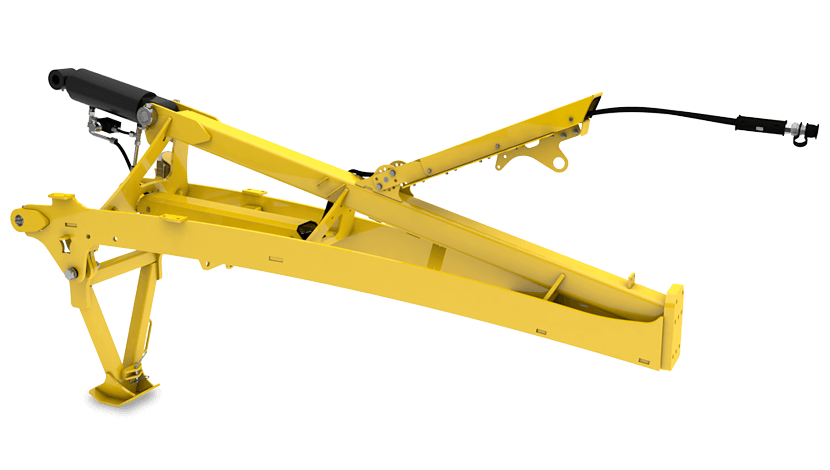

The ATLAS AO_PROFI high speed disc is equipped with a hydraulic drawbar. We use this technical design as it facilitates the connection to the tractor, and above all, improves the quality of work because the speed disc perfectly contours any terrain unevenness.

The ATLAS AO_PROFI high speed disc can be equipped with the BEDNAR ALFA DRILL seeder while in production, for seeding cover crop and small-seed plants during tillage, all in one pass. The time and fuel savings are considerable. The seeder has a capacity of 11 bu.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working tools of the high speed disc.

A hydraulically adjustable drawbar contributes to perfect terrain contouring and levelling any unevenness.

Provide excellent terrain contouring and maintain the set working depth along the entire width of the implement.

Blade gang with notched or aggressive discs, with a diameter of 24″×0.24″ and auto-reset protection of each blade arm

Provides even distribution of the machine weight, contributes to better stability, and eliminates the risk of speed disc boucing at higher working speed. Another advantage lies in the reduced turning radius at headland and high manoeuvrability, even in rugged terrain.

The wide range of rear packers make it possible to adjust the implement to any conditions. Double packer layout prevents speed disc boucing during work. The packers help close the surface and prevent evaporation of soil moisture.

It perfectly levels any minor unevenness and evenly spreads clods along the entire machine width.

“We like how the implement works, that’s why we chose it. In my opinion, the main advantage of ATLAS AO_PROFI is the high underframe clearance, which is essential due to the large quantities of trash. I also like the spring-loading of each blade using the reset protection.The integrated axle at the centre of the tool makes transportation safe and easy to turn. The aggressive blades with a diameter of 24″ work beautifully.”

Hak, co-owner, PLOTISTSKA ZELENINA – HAK s.r.o., (district of Hradec Kralove), Czech Republic

We know that everyone has different requirements for the optional implement equipment and its expected use. Therefore, you can specify your own ATLAS AO_PROFI speed disc to precisely match your needs.

The leveler in front of the double packers levels any unevenness after the previous section. The packers only consolidate the soil without levelling it. The result is a perfectly level field.

![<![CDATA[Crushbar_levelling_bar_2024]]><![CDATA[Crushbar_levelling_bar_2024]]>](https://www.bednar.com/wp-content/uploads/prislusenstvi/crushbar_levelling_bar.png)