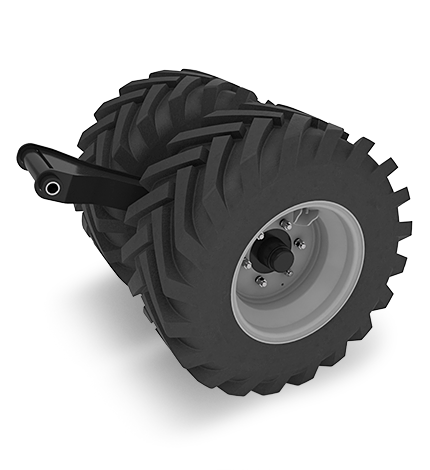

Double front support wheels

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

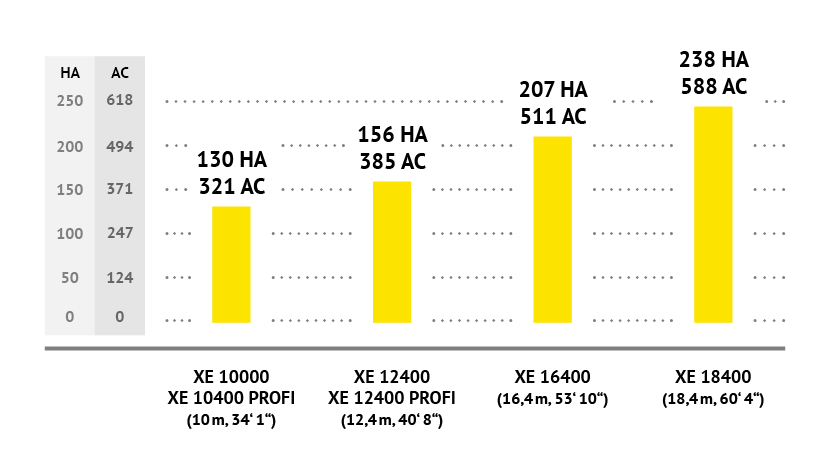

Proven technical solution and maximum daily performance. These are the main features of the SWIFTERDISC XE wide working width compact disc harrow. Its characteristics make it suitable for shallow soil preparation and intensive mixing of crop residues with the soil. The SWIFTERDISC XE machines are available in working widths of 10 and 12.4 metres. The unique technical solution of folding the disc sections forward allows for compact dimensions for transport.

2-14 cm

10-12.4 m

350-500 hp

SWIFTERDISC XE compact disc harrows offer a series of technical solutions that make them suitable for both shallow stubble cultivation and seedbed preparation

Stubble cultivation is one of the most important operations. According to proper agrotechnical procedures, it should be performed as soon as possible after harvest. For this operation, the SWIFTERDISC XE can be equipped with notched disc or aggressive discs with a diameter of 520 × 5 mm or 560 × 5 mm, which ensure excellent cutting, soil mixing, and incorporation of crop residues. The rear packers then consolidate and close the worked soil profile for even weed and volunteer seedlings emergence.

The small diameter of the discs combined with high working speeds allows high circumferential speeds to be achieved, ensuring excellent crumbling and mixing effects of the disc section. Especially for more frequent use in soil preparation, we recommend equipping the SWIFTERDISC XE compact disc harrow with a front Crushbar levelling bar, which is used to level unevenness and break up rough furrows.

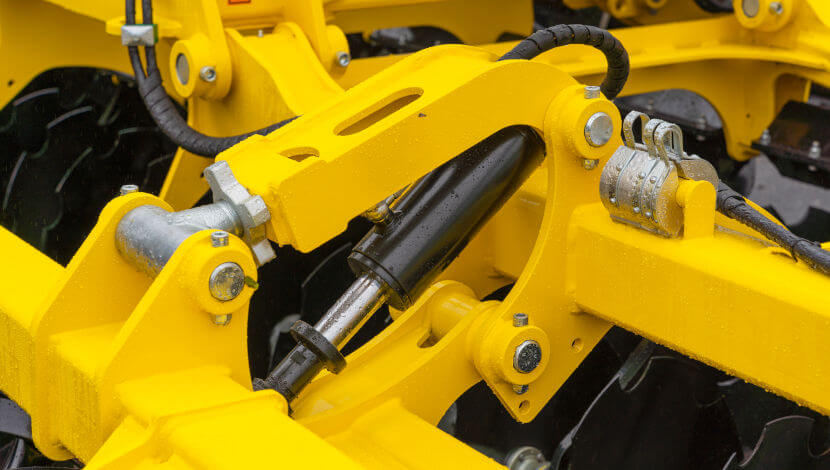

The exact setting of the required working depth is carried out hydraulically. The working depth of the machine can be easily adjusted using spacers on the hydraulic cylinders of the disc harrows.

To increase year-round use, the SWIFTERDISC XE wide working width compact disc harrow can be fitted with a hydraulically controlled Crushbar in front of it. This combination ensures perfect levelling of the soil profile, crumbling of clods, and soil preparation.

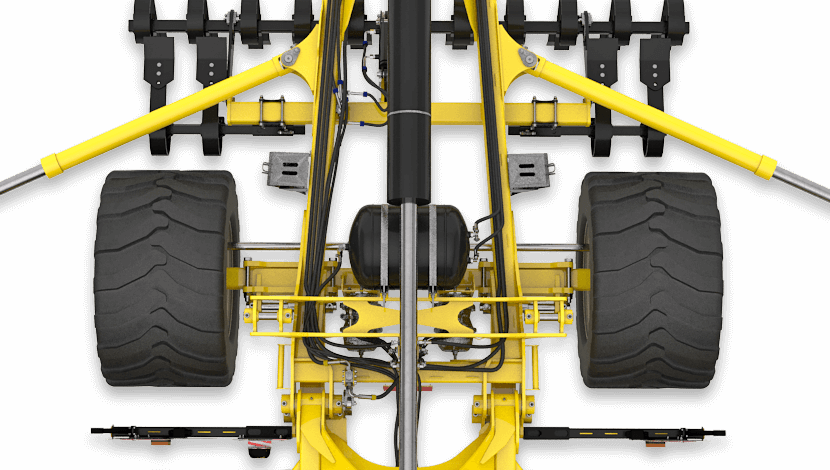

SWIFTERDISC XE wide working width copact disc harrows have a transport axle positioned in front of the first row of disc sections. This solution contributes to ideal weight distribution of the machine and allows for higher working speeds. Telescopic rods help stabilise the frames on which the disc sections are mounted.

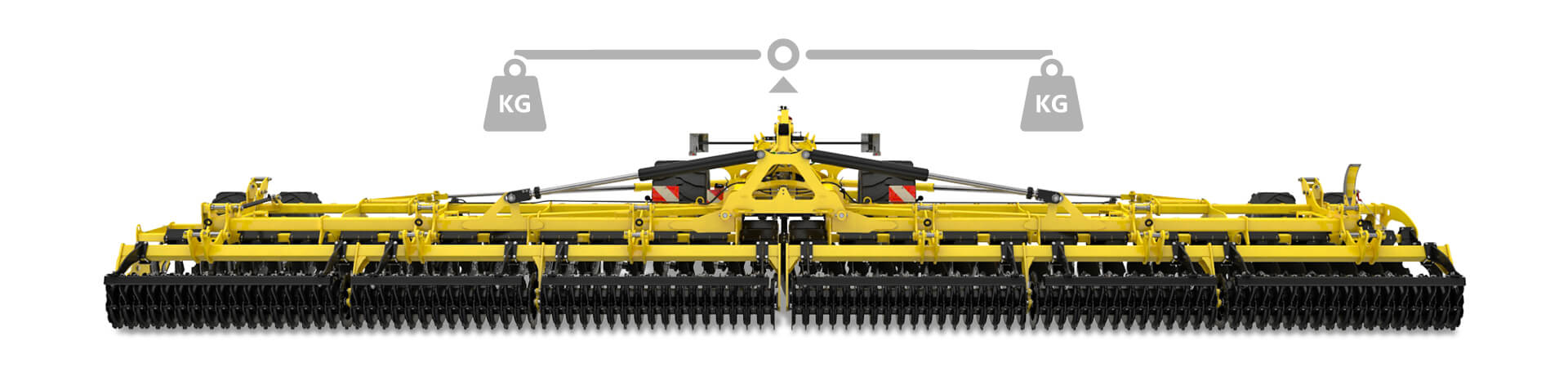

The basis for high-quality tillage is maintaining the set working depth for uniform cultivation of the soil profile. SWIFTERDISC XE compact disc harrows have the same pressure on the discs across the entire working width of the machine, even at the edges of the harrow, thanks to the forward-mounted axle and the concept of two folding side frames. The machine’s design reduces the number of hydraulic cylinders where pressure loss to the side frames could occur. This solution also contributes to a low number of lubrication points, reduces overall machine wear, and simplifies machine handling both in the field and during transport.

The SWIFTERDISC XE wide working width compact disc harrow is very easy to maneuver at headlands. The machine turns on the rear rollers and front support wheels at headlands, only the disc working section is dug in without the need to lift the entire frame. This solution eliminates negative load on the hitch and lightens the tractor when the machine is at the headland.

Even with a working width of 12.4 metres, the SWIFTERDISC XE compact disc harrow is very compact during transport, as it does not exceed a transport width of 3 metres and the height of the machine is less than 4 meters. This is mainly due to the side frames folding forward onto the drawbar.

The SWIFTERDISC XE compact disc harrow can be equipped with the BEDNAR ALFA DRILL seeder for sowing catch crops and small-seeded plants during stubble cultivation in a single pass. The savings in time and fuel are significant in this case. Hopper capacity 800 litres.

SWIFTERDISC compact disc harrows are designed for coupling with the most powerful tractors on the market. Thanks to their sophisticated design and high working speed, these harrows offer maximum daily output.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise overview of the main working parts of the compact disc harrow.

Provides ideal distribution of the machine weight and contributes to precise adherence to the set working depth thanks to the identical downforce on the disc section.

Provides excellent terrain contouring and maintains the set working depth along the entire width of the machine.

The hydraulically controlled Crushbar levelling bar is especially suitable for initial surface levelling and for breaking the rough furrow before the disc section. The individual leveller paddles are reinforced. It is easily controlled using the hydraulic circuit from the comfort of the cabin.

Disc section with notched or aggressive discs, with a diameter of 520 / 560 × 5 mm, and high throughput thanks to the Twin-Disc system.

Provides safe turning at headlands and enables the forward side frame folding.

The wide range of rear packers and rollers makes it possible to adjust the machine to any conditions.

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTERDISC XE versatile wide working width disc harrow to precisely match your needs.