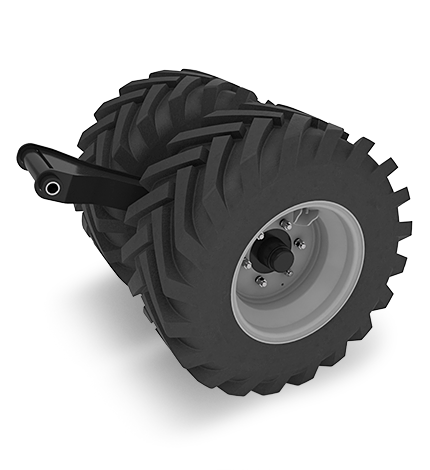

Double front support wheels

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

SWIFTERDISC XO_PROFI is a new product range of short compact disc harrows in the BEDNAR range. The PROFI designation brings customers a number of advantages in the form of new technical solutions. SWIFTERDISC XO_PROFI models excel in high working speeds, first-class workmanship, and excellent quality of the final result.

2-14 cm

6,25 -7,25 m

250-350 hp

The SWIFTERDISC XO_PROFI product range is a professional series of compact disc harrows, which are suitable for post-harvest tillage as well as for seedbed preparation.

Stubble cultivation is one of the most important operations. According to proper agrotechnical procedures, it should be performed as soon as possible after harvest. For this operation, the SWIFTERDISC XO_PROFI can be equipped with notched discs or aggressive discs with a diameter of 520 × 5 or 560 × 5 mm, which ensure excellent cutting, soil mixing, and incorporation of crop residue. The rear packers then consolidate and close the processed soil profile for even weed and volunteer emergence.

The small diameter of the discs combined with high working speeds allows high circumferential speed to be achieved, ensuring excellent crumbling and mixing effects of the disc section. Especially for more frequent use in soil preparation, we recommend equipping the SWIFTERDISC XO_PROFI compact disc harrow with a front Crushbar, which is used to level unevenness and break up rough furrows.

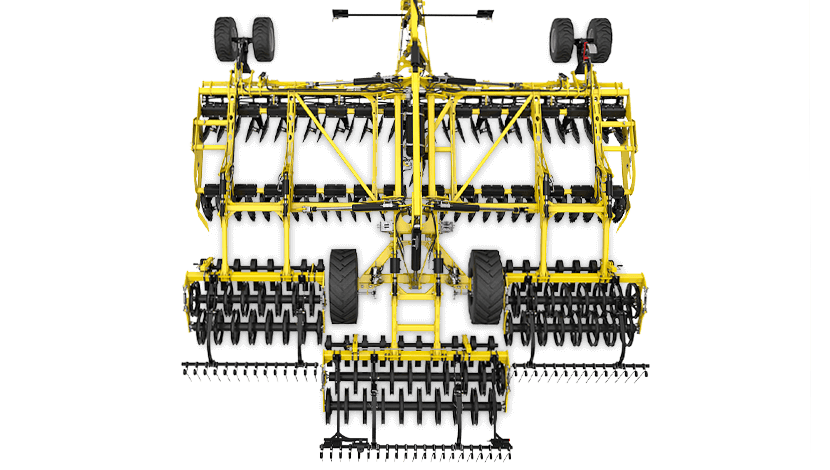

SWIFTERDISC XO_PROFI machines have disc sections arranged in an “X” pattern. This innovative technical solution eliminates sideways movement of the machine, known as drifting. As a result, the compact disc harrow precisely follows the tractor’s line. The center disc eliminates the risk of ridges forming.

The arrangement of the rear packers in two rows provides greater stability at high speeds than a single row and also eliminates the gap that occurs with compact disc harrows that use two rollers in one row. The integrated axle ensures even weight distribution and eliminates rocking of the machine. It also makes transport safer and reduces the turning radius of the tractor with the harrow at headlands.

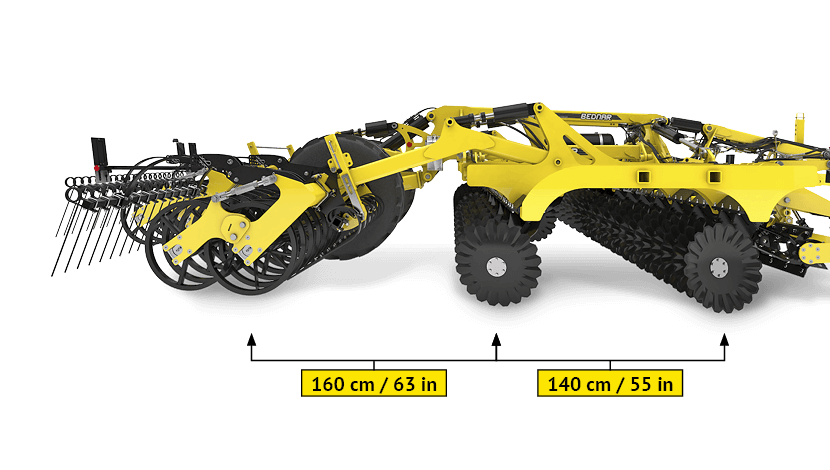

When stubble cultivation or incorporating large amounts of crop residues, the machine can often become clogged due to low throughput, or the working speed may be limited to prevent the formation of waves. SWIFTERDISC XO_PROFI compact disc harrows provide 140 cm between the front and rear disc rows and up to 160 cm between the discs and the rear packer axle. The 60-centimeter frame throughput allows for the incorporation of even large amounts of organic matter or manure.

SWIFTERDISC XO_PROFI can be equipped with a system of brackets that form track eradicators behind the tractor wheels for perfect loosening of compacted soil layers. Using spacers, it is possible to increase the working depth of 4 to 8 discs compared to the others in the front row by 2-4 cm.

The SWIFTERDISC XO_PROFI compact disc harrow is equipped with a hydraulic drawbar. We use this technical solution because it facilitates connection to the towing vehicle and, above all, improves the quality of work, as the disc harrow perfectly follows the unevenness of the terrain.

The SWIFTERDISC XO_PROFI compact disc harrow can be equipped with a Trash Cutter cutting roller in front, which is ideal for cutting plant residues and tough stalks. The chopped crop residues decompose better in the soil and facilitates subsequent tillage, during which the machine does not clog.

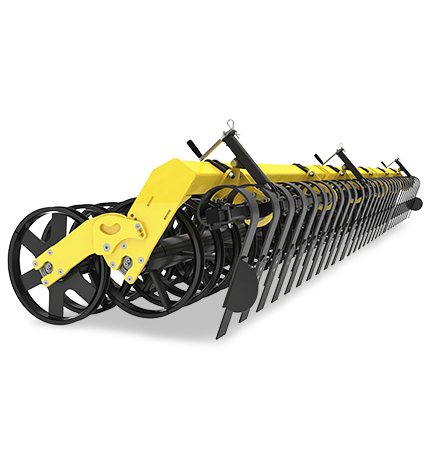

The SWIFTERDISC XO_PROFI compact disc harrow can be equipped with the BEDNAR ALFA DRILL seeder for sowing catch crops and small-seeded plants during stubble cultivation in a single pass. The savings in time and fuel are significant in this case. The hopper capacity is 400 litres.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise overview of the main working parts of the compact disc harrow

The hydraulic drawbar contributes to perfect terrain contouring.

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

Disc section with notched or aggressive discs, with a diameter of 520 / 560 × 5 mm.

Provides even distribution of the machine weight, contributes to better stability, and eliminates the risk of machine swaying at higher working speed. Another advantage lies in the reduced turning radius at headlands and high manoeuvrability, even in rugged terrain.

The wide range of rear packers make it possible to adjust the machine to any conditions. The packers crumble clods and consolidate soil to prevent its drying.

„We began working with BEDNAR in 2014 with the purchase of a SWIFTERDISC XO 8000 F compact disc harrow. After eight years of effective stubble cultivation, we were very satisfied with its performance, especially with the aggressive discs. Therefore, we decided to switch to the XO 7500 PROFI model, fully equipped with an ALFA DRILL seeder for seeding catch crops, large aggressive discs with a diameter of 560 mm, and a TRASH-CUTTER roller. We are very satisfied with the efficiency of the TRASH-CUTTER roller, as it has completely replaced our mulcher and allows us to perform two operations in a single pass.“

Jean-Michel Joppé, Farmer

Somme-Vesle, France

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTERDISC XO_PROFI cultivator to precisely match your needs.

The levelling bar, placed in front of the rear double packers is used for levelling off any unevenness after the previous section. The packers only consolidate soil, they do not level it. The outcome is a perfectly levelled field.