MATADOR MO is a seed drill for strip-till seeding, which performs deep loosening with tine section, targeted fertiliser placement and seeding in a single pass. This reduces the number of passes, limits soil erosion and creates perfect conditions for seed germination. It is available in a 6 m or 4,5 m working width version with a 5,000 litre double-chamber pressurised hopper.

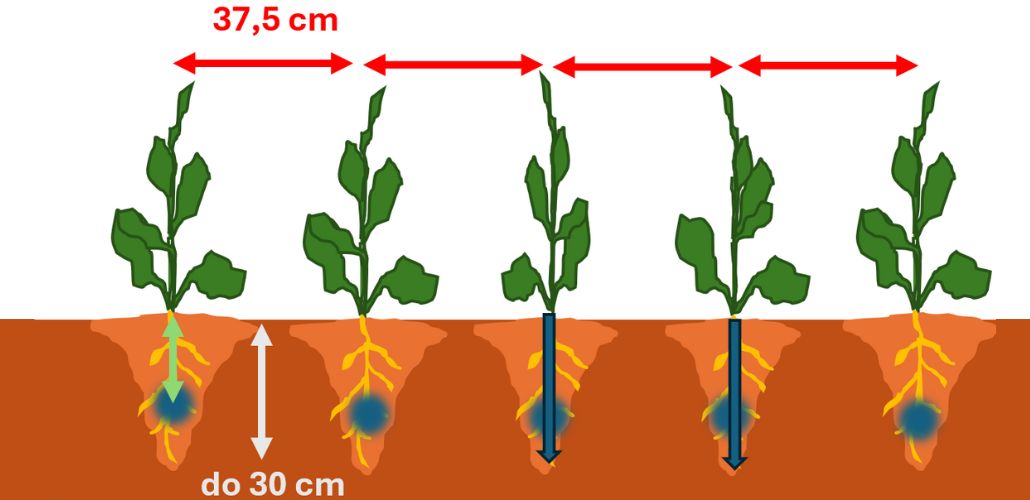

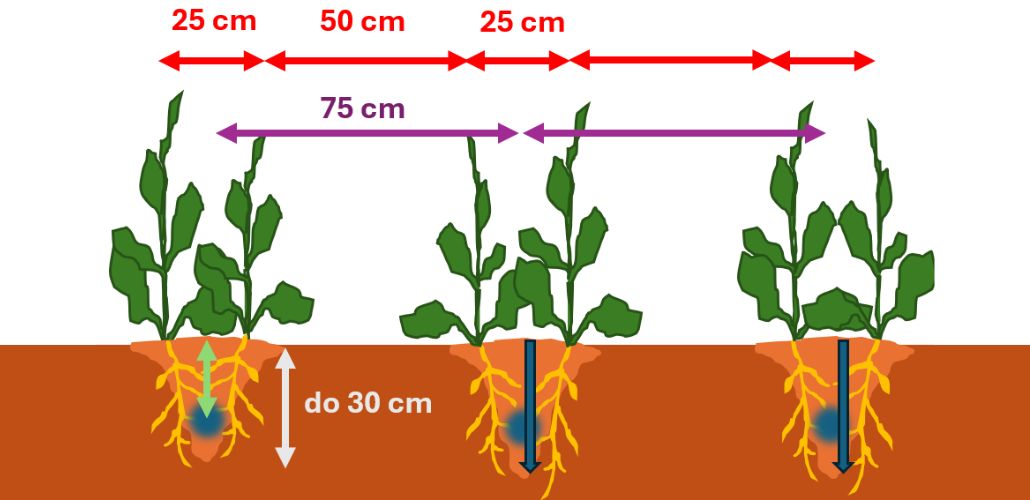

The tine section is designed to allow zonal loosening of the soil only in the strips where the seed and fertiliser are deposited. The loosened part allows for more efficient infiltration of rainwater, better soil warming and precise placement of seed and fertiliser into the soil profile. In contrast, the uncultivated zone protects the soil structure, does not release carbon from the soil and maintains soil capillarity. The design offers two tine spacing options – 37.5 cm or 75 cm.

Depending on the tine section adjustment, seeding can be carried out in two ways. The first option (tine spacing 37.5 cm) offers drilling directly into the loosened strip behind the tine. The seed is thus placed directly in the centre of the loosened zone. The second option (tine spacing 75 cm) allows the seed to be placed on the sides of the loosened strip in two rows with a spacing of 25 cm and a row spacing of 50 cm.

Fertiliser is distributed from the hopper directly behind the individual tine and deposited at the bottom of the created strip. By placing the fertiliser at a suitable distance from the seed (ideally 12-18 cm depending on conditions), the plant roots are forced to penetrate deeper into the soil. Deep rooting increases plant resistance to drought or low temperatures, which can have a very negative impact on plant development.

Farmers at three farms in northern Germany were able to try out the machine’s technology for themselves. Using the MATADOR machine, each farmer drilled winter rapeseed on their field, covering an area of approximately 10 hectares.

The first field was located near the Polish border in the federal state of Macklenburg-Vorpommern.

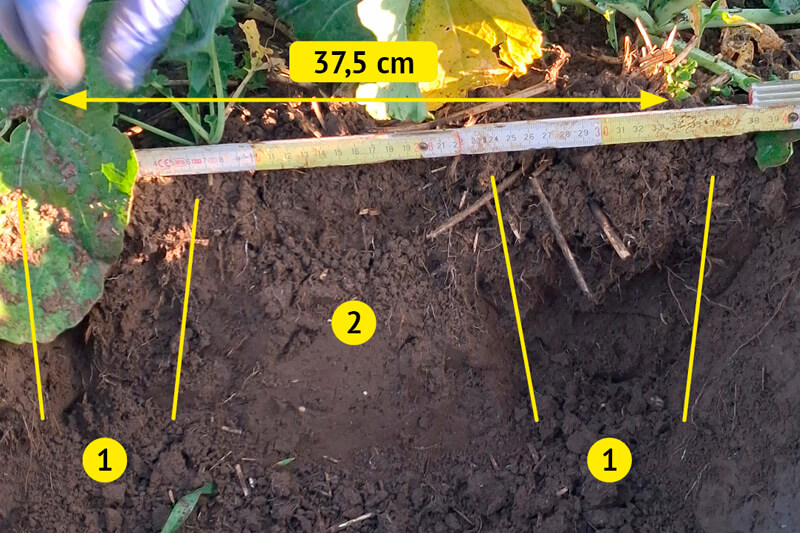

Here, the farmer used the MATADOR machine to seed rapeseed in rows spaced 37.5 cm apart. The loosening depth was set to 23 cm, which also corresponds to the depth of fertiliser placement.

1 – tilled strip

2 – untilled zone

After the crop was established, insecticide was applied twice and growth regulators were also used twice.

The results can be assessed as very positive so far. The function of the loosened zone was clearly evident, allowing the roots to penetrate into the deeper layers where the fertiliser was deposited. The result was a high-quality root system that enables the plant to survive tough conditions.

The second plot was located in a similar location near the city of Schwerin. After harvesting the barley, the soil was lightly loosened to a depth of 5 cm. For following seeding, the MATADOR machine was set to a depth of 28 cm and a spacing of 37.5 cm in the tine section.

However, the result was not as expected, as can be seen in the previous picture. The spacing of the seeding coulters was set to 25 cm, which means that the seeds could not be placed in the loosened zone. The same downforce per drill coulter apparently caused the disc to penetrate too deeply into the loosened zone, where the seeds subsequently remained. Other seeds, on the other hand, were deposited in the strip with compaction, untilled soil, where water is less easily absorbed and the root system develops with difficulty. This most likely caused irregular and uneven plant emergence, as each seed had completely different conditions for germination.

The result shows how important it is to set up the machine correctly in front of operation, including a final check directly in the field.

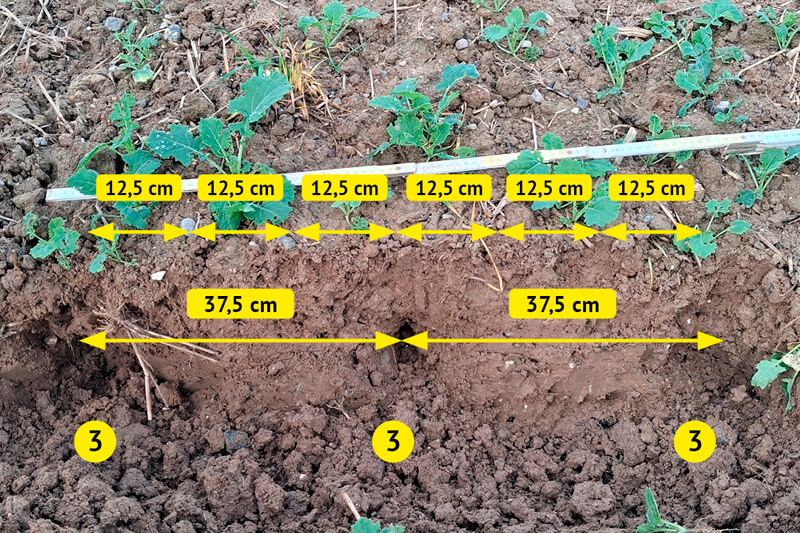

The third site was already part of the neighbouring federal state of Schleswig-Holstein. Here, farmers tried seeding rapeseed in very hilly terrain.

The tine spacing was set to 37.5 cm and the seeding coulter spacing to 12.5 cm. The narrow row system may not be the most advantageous for establishing rapeseed crops.

3 – tilled strip

Probably thanks to the previous loosening of the soil to a depth of 15 cm after the wheat harvest, the conditions for crop emergence were good enough for the crop to germinate almost evenly. The usual unevenness can be seen on sloping sections where the tractor does not have sufficient power and speed for precise work. It should also be noted that, due to the previous loosening, the tractor with the machine loses traction more easily.

However, it should not be forgotten that every operation in the field costs money. Therefore, if farmers subsequently loosened the soil to a depth of over 20 cm with the MATADOR machine without any effect on the proper placement of seeds in the loosened strip, this operation was, at the very least, unnecessarily costly.

In conclusion, the MATADOR machine, which can be used for intensive strip tillage, certainly stands up well in comparison with its competitors. However, it is necessary to pay close attention to the correct adjustment of all parts of the machine. A correctly adjusted MATADOR can limit the number of passes across the field by combining several operations and at the same time protect the soil and soil organisms thanks to its zonal tillage technology.

JOY OF FARMING

[email protected]

BEDNAR FMT s.r.o.