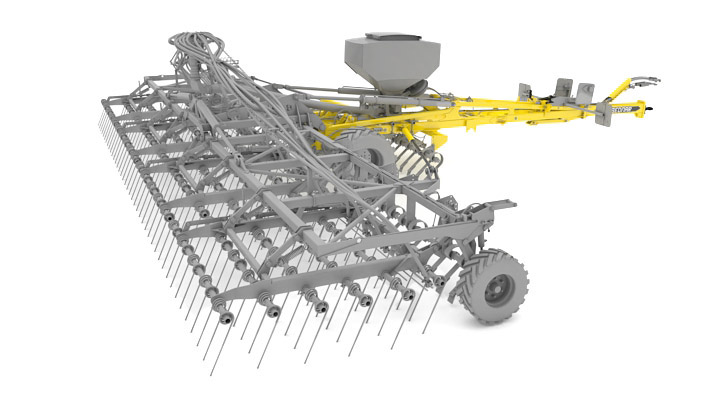

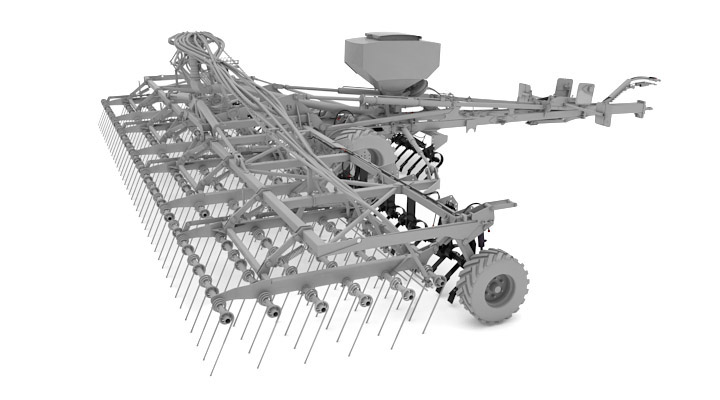

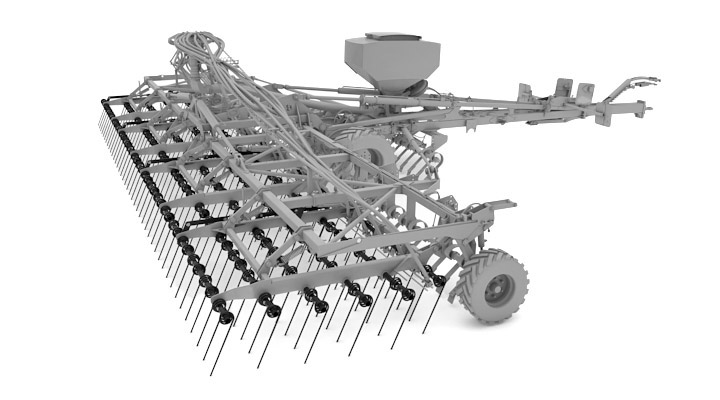

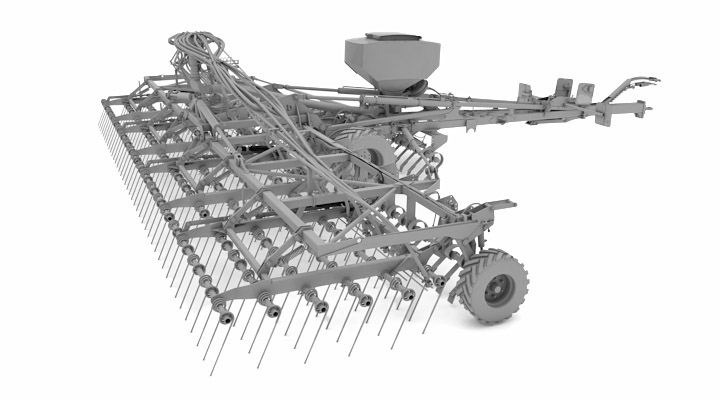

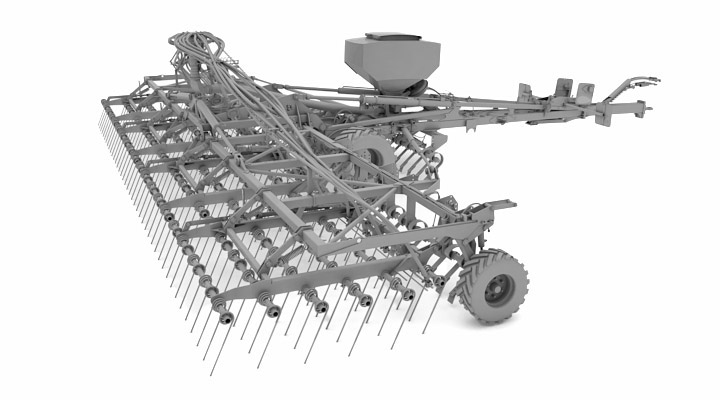

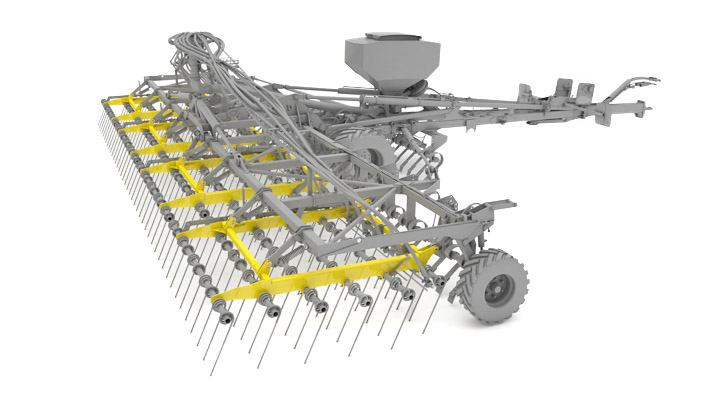

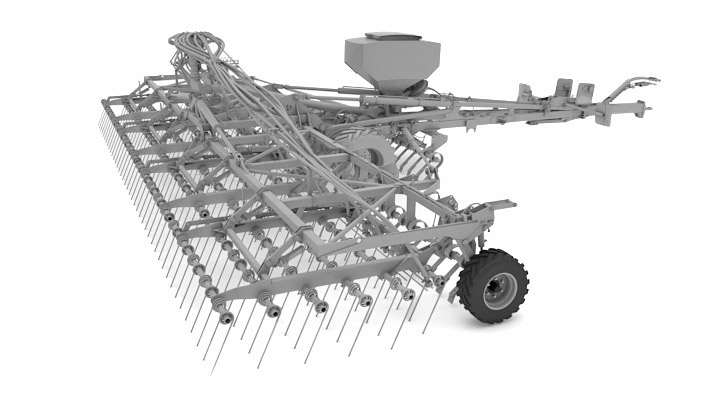

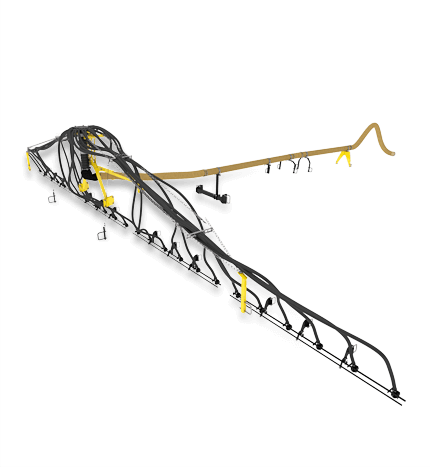

STRIEGEL-PRO PE TRAILED STRAW HARROW

A simple machine with many agronomic advantages.

- Soil cultivation

- Maintenance of meadows and pastures

- Disruption of soil crust

- Crop residue distribution

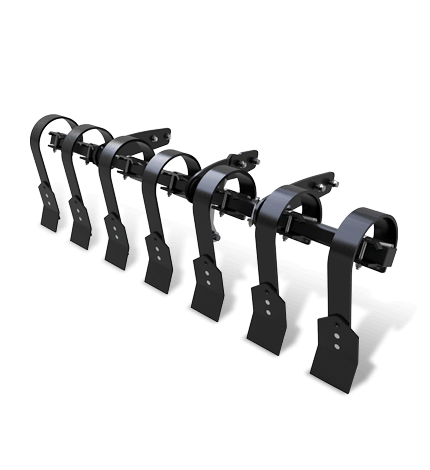

The STRIEGEL-PRO PE trailed straw harrow brings many agronomic advantages and offers a wide range of usage. It is primarily designed for even distribution of crop residues after harvest and for stimulating the emergence of volunteer plants. However, it can also be used during light spring soil cultivation, aeration of cereals or permanent grassland, including the option of fertilisation or seeding catch crops in one pass.

The STRIEGEL-PRO PE trailed straw harrow brings many agronomic advantages and offers a wide range of usage. It is primarily designed for even distribution of crop residues after harvest and for stimulating the emergence of volunteer plants. However, it can also be used during light spring soil cultivation, aeration of cereals or permanent grassland, including the option of fertilisation or seeding catch crops in one pass.

The STRIEGEL-PRO PE trailed straw harrow brings many agronomic advantages and offers a wide range of usage. It is primarily designed for even distribution of crop residues after harvest and for stimulating the emergence of volunteer plants. However, it can also be used during light spring soil cultivation, aeration of cereals or permanent grassland, including the option of fertilisation or seeding catch crops in one pass.

The STRIEGEL-PRO PE trailed straw harrow brings many agronomic advantages and offers a wide range of usage. It is primarily designed for even distribution of crop residues after harvest and for stimulating the emergence of volunteer plants. However, it can also be used during light spring soil cultivation, aeration of cereals or permanent grassland, including the option of fertilisation or seeding catch crops in one pass.

BEDNAR FMT

BEDNAR FMT