November

2025

Test results: principle and benefits of…

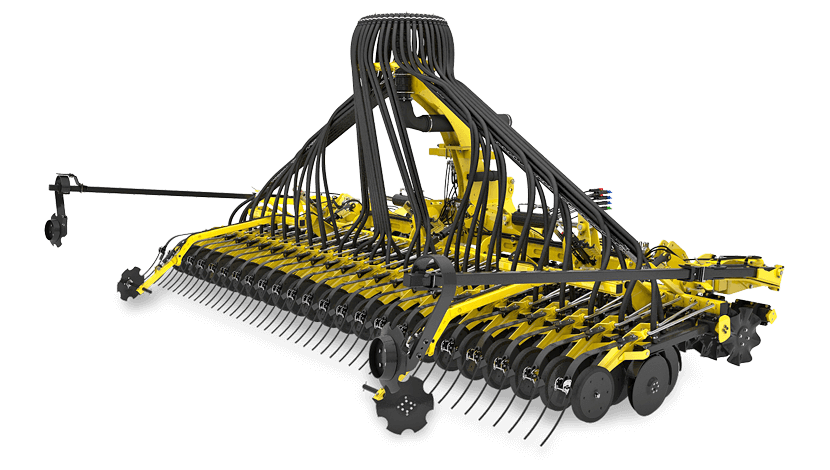

MATADOR MO is a seed drill for strip-till seeding, which performs deep loosening with tine section, targeted fertiliser placement and seeding in a…

The MATADOR MO seed drill is designed for the strip till seeding technology. Strip-tillage with simultaneous drilling brings a new approach to crop establishment. The layout of the tines is based on the new agronomic and legislative trends in withdrawal of herbicides at the expense of mechanical crop treatment.

4,5-6 m

210-400 hp

5000 l

A seed drill for strip-till systems responding to the new agronomic trends in crop establishment.

MATADOR MO is a perfect combination of a seed drill that manages tillage and seeding in one pass. The advantage of this procedure lies in loosening soil in the strips of future crop roots and precise fertiliser placement. The strip-till technology offers interesting agronomic benefits in the form of moisture preservation, anti-erosion protection or reduction in the number of passes across the field.

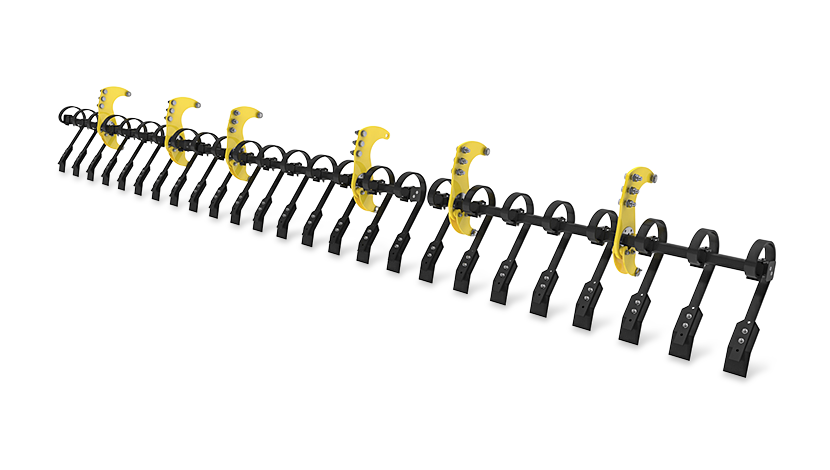

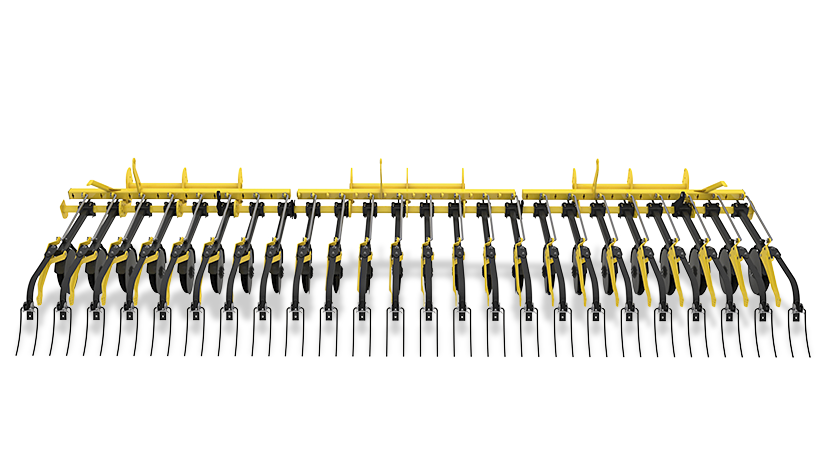

The MATADOR MO is equipped with ACTIVE-MIX tines for active loosening up to a maximum depth of 35 cm with the option of placing fertiliser in the soil profile or on the soil surface. The tines are equipped with hydraulic reset protection reaching maximum release force of 870 kg (maximum lift height of 30 cm). The tines can be equipped with 40 or 80 mm points in LONG LIFE version.

The disc section works behind the tines and it is hydraulically adjustable. The disc section can be set to level soil in front of the off-set tyre packer (suitable for most types of cereals) or to create ridges (suitable for rapeseed).

The MATADOR MO seed drill is equipped with a double-chamber hopper with a total capacity of 5,000 litres (40:60 ratio). The MATADOR MO hopper is pressurised. Overpressure is created in the hopper thanks to the airtight closure. This technical design allows for dosing large batches with high precision independent of the size of the seeds/fertiliser.

Behind the disc section is a tyre packer with large diameter wheels (280/85 R20). The tyre packer is arranged in two rows (off-set arrangement) with each wheel mounted independently. The independent mounting of the wheels means easy replacement in the event of a puncture. The double-row arrangement reduces the tractor’s power demand, the packer has an excellent self-cleaning effect and seed drill is highly stable.

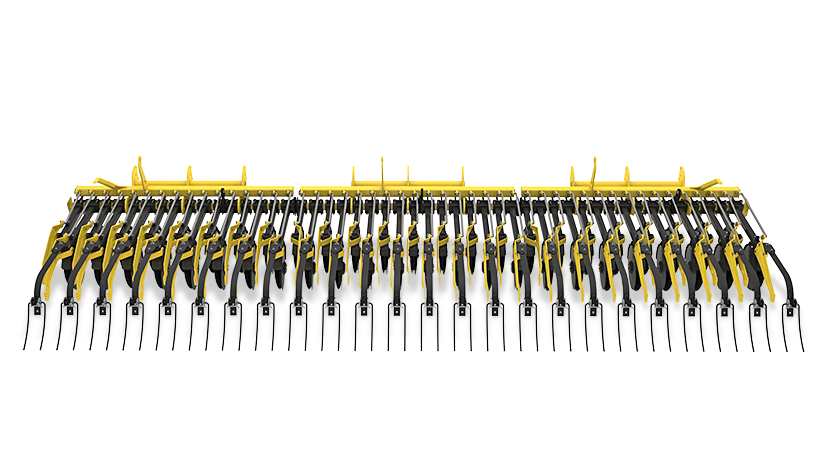

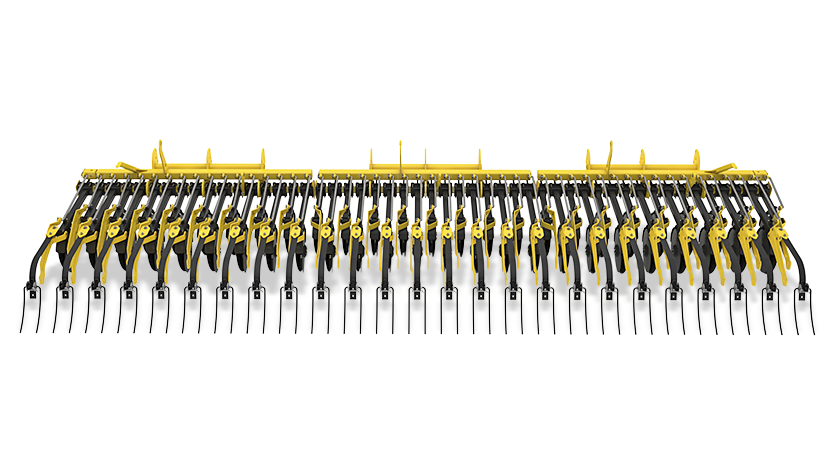

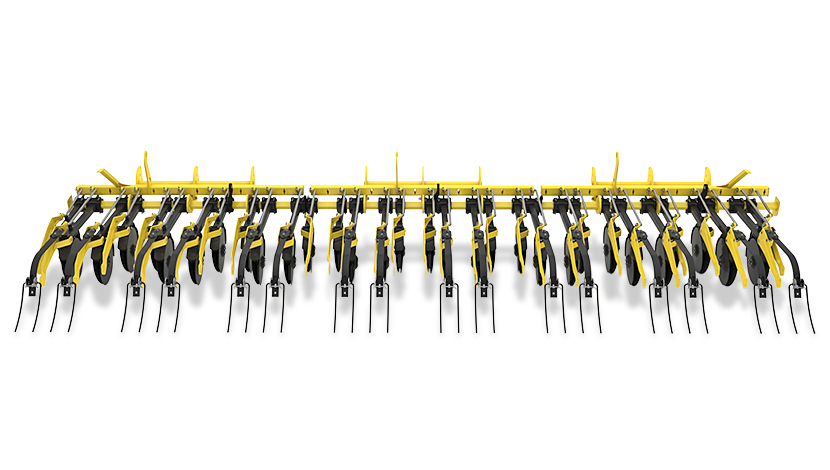

CORSA CN is a versatile seed bar of 4,5/6 metres working width that is connected to the MATADOR MO seed drill thanks to its three-point hitch. The standard equipment of the seed bar includes double-disc seeding coulters with individual PSP system (parallel linkage) ensuring quality and even crop establishment.

GIRONA GN is a versatile mounted tine seed drill. It is used for seeding crops in conditions with a large amount of post-harvest residue, on lighter soil types or in conditions with stones or high levels of moisture. The seeding coulter is equipped with a 20 x 200 mm point in the LONG-LIFE design, which guarantees maximum durability and a long service life.

The Crushbar levelling bar is used for initial levelling of the furrows and terrain unevenness. The working angle of the levelling bar can be modified hydraulically during the work from the tractor cab.

The Frontpack with a diameter of 390 mm ensures even soil profile levelling and back soil consolidation in front of the drill coulters.

TURBO coulters are sharp discs with a diameter of 400 mm. The TURBO coulter cuts crop mulch and soil. TURBO coulters work in the same line as the rear drill coulters. The coulter row spacing is 12.5 cm. The TURBO coulter downforce can be modified hydraulically during the work from the tractor cab.

PROFI coulters are specially shaped discs with a diameter of 400 mm, offering an excellent crumbling effect. They are suitable for quality tillage of heavy soils. The PROFI coulter downforce can be modified hydraulically during the work from the tractor cab.

Suitable row spacing for establishing cereal with a profile soil fertilisation of all the surface.

Suitable row spacing for establishing cereals with a profile soil fertilisation of all the surface. The seeding bar is equipped with double edge drill coulters. The seed flow splits into two parts with the double edge drill coulters, which prevents creating empty spots between follow-up passes.

Suitable row spacing for establishing cereals with a profile soil fertilisation of all the surface. This organisation enables mechanical weeding between the rows.

Suitable row spacing for establishing winter rapeseed in double rows with a row spacing of 12.5 cm. The double rows get fertilisation from the fertilised strips with a row spacing of 37.5 cm. This organisation enables mechanical weeding between the rows.

Emphasis was placed on easy control when developing the MATADOR MO seed drill. The seed drill can be connected to the tractor via the ISOBUS technology, or it can be controlled using a BEDNAR ISOBUS display. A series of control displays with basic or advanced control functions are available.

BEDNAR developers designed an application for mobile phones that provides easy and simple calibration of the seed drill from your mobile phone. The mobile application includes a guide that helps with the right selection of the seed metering roller based on the type of seeds/fertiliser, working speed and seeding amount.

Besides the standard seed bar in the rear three-point hitch, the MATADOR MO seed drill can also be connected with a precision planter for planting corn, sunflower or sugar beet. The row spacing of 37.5 cm with an option to deactivate every other tine enables crop organisation with an row spacing of 75 cm. In one pass, you will loosen, fertilise your soil and establish the crop. The technology brings considerable savings in time and financial costs.

The MATADOR MO seed drill can be equipped with the BEDNAR ALFA DRILL seeder while in production, for even higher machine versatility and crop establishment options. The seeder can be used for seeding a third type of seeds or applying micro-granulate. The seeder is pressurised and has a capacity of 400 litres. The control of the seeder is integrated into the control interface of the MATADOR MO.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the strip-till seed drill.

Contributes to excellent terrain contouring and easy connection to various types of tractor hitches.

A double-chamber hopper with the total capacity of 5,000 litres. The pressurised hopper offers high dosing accuracy.

The ALFA-DRILL seeder allows seeding a third type of seeds or applying micro-granulate when both hopper chambers are used for seeds.

The three-point hitch, category III is used for connecting the seed drill to the CORSA CN seed bar or precision planter.

It may be equipped with drill coulters with a row spacing of 12.5 or 25 cm. Double edge drill coulters are also available. Off-set tyre packer

The large diameter of the individual tyres and the off-set layout offer excellent self-cleaning effect. The packer consolidates soil after work.

The tine section is equipped with robust hydraulic reset tine protection.

The disc section is hydraulically adjustable. It is used for reverse soil levelling or creating ridges in front of the tyre packer.

Comfortable calibration of the seed metering unit and easy emptying of seeds/fertilisers from the hopper.

The double front support wheels with mechanical setting stabilise the seed drill. The seed drill works in the plane.

„Thanks to its front band skid and disc section, the OMEGA OO_FL handles even heavy clay soil excellently, preparing the seed bed to a high standard and ensuring that the seed is evenly distributed. I am satisfied with the seeding quality. We purchased the seed drill because of the technical parameters it was supposed to meet – seeding two crops, mid-row fertiliser placement, and reducing the number of passes thanks to soil tillage.“

Dominik Markovič,

agronomist, Zemědělská družstvo Dolany, Dolany (okres Náchod , ČR)

STRIP-TILL SEEDING WITH TARGETED FERTILISER PLACEMENT

The strip-till technology with simultaneous fertiliser placement and seeding in tilled strips offers many agronomic benefits, including erosion control, reduced field traffic, and water conservation. The tine section ensures the removal of compacted soil layers and quality tilling of strips with the possibility of simultaneous fertiliser application. Subsequently, the seeds are placed in the tilled strips, providing plants with sufficient nutrients and promoting the development of a healthy root system.

| MATADOR MO | MO 4500 | MO 6000 | |

|---|---|---|---|

| Working width | m | 4,5 | 6 |

| Transport width | m | 3 | 3 |

| Transport length | m | 10,3 | 10,3 |

| Transport height | m | 4 | 4 |

| Number of tines | pcs | 12 / 6 | 16 / 8 |

| Tine spacing | cm | 37,5 / 75 (35 / 70) | 37,5 / 75 (35 / 70) |

| Tine distance in a row | cm | 75 | 75 |

| Max. working depth of tines* | cm | 35 | 35 |

| Type of tine protection | hydraulic (downforce of 870 kg) | hydraulic (downforce of 870 kg) | |

| Drill coulter spacing - CORSA CN | cm | 12,5 / 17,3 / 25 / 35 / 37,5 / 12,5-25 / 25-50 | 12,5 / 16,7 / 25 / 12,5-25 / 25-50 |

| Number of drill coulters - CORSA CN | 36 + 2 / 26 + 2 / 18 / 12 / 12 / 24 / 12 | 48 + 2 / 36 + 2 / 24 / 32 / 16 | |

| Drill coulter down pressure - CORSA CN | kg | 100 | 100 |

| Drill coulter spacing - GIRONA GN | cm | 37,5 | 37,5 |

| Number of drill coulters - GIRONA GN | cm | 12 | 16 |

| Drill coulter down pressure - GIRONA GN | kg | 130 | 130 |

| Hopper volume | l | 5000 | 5000 |

| Hopper chamber ratio | 60:40 | 60:40 | |

| Filling height | m | 3 | 3 |

| Volume of BEDNAR ALFA DRILL hopper* | l | 400 | 400 |

| Frame type | folding | folding | |

| Power demand* | HP | 210 - 280 | 280 - 400 |

| Hitch type | crossbar cat. III / towing eye 40, 51 / K80 | crossbar cat. III / towing eye 40, 51 / K80 | |

| Packer tyre dimensions | 280/85 R20 | 280/85 R20 | |

| Max. total weight without seeding bar** | kg | 7800 | 8900 |

| Total weight with seeding section (row spacing of drill coulters 12.5 cm)** | kg | 10500 | 11200 |

* depends on soil conditions ** not included in the basic equipment *** according to the machine equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.