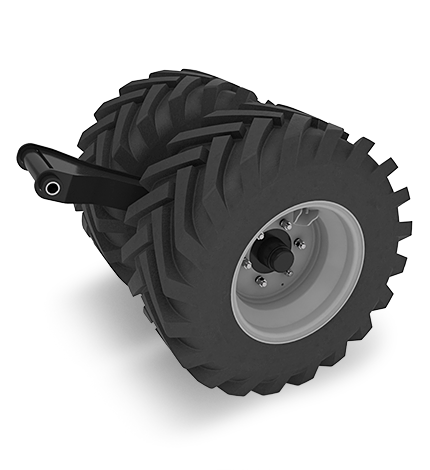

Double front support wheels

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

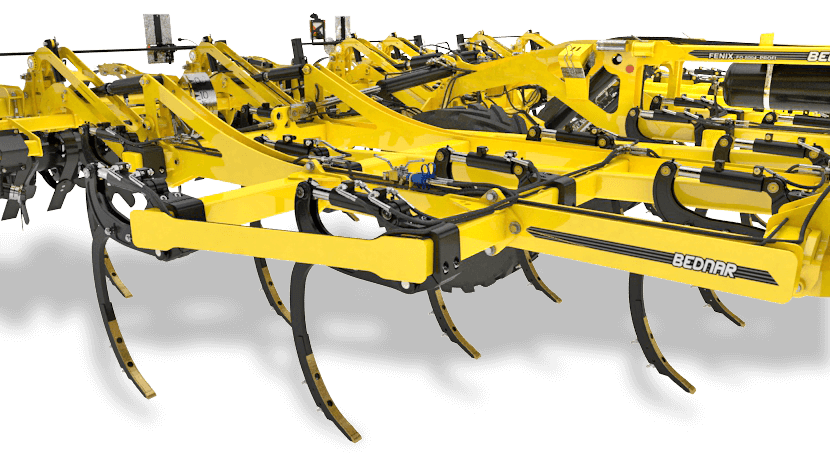

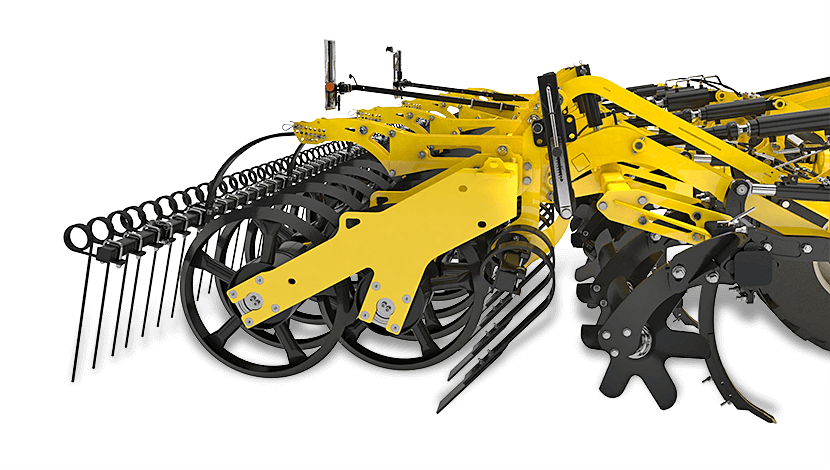

The FENIX FO_PROFI tine cultivator is a new generation of tine cultivators for intense shallow soil cultivation after harvest, as well as deep cultivation of up to 35 centimetres prior to crop establishment. The FENIX FO_PROFI semi-mounted tine cultivator has tines arranged into four rows in the shape of an arrow. The well-thought-out design reduces traction resistance and tractor power demands.

35 cm

4-7,9 m

200-620 hp

A tine cultivator for deep soil cultivation of up to 35 centimetres, including shallow stubble cultivation after harvest.

The models of the FENIX FO_PROFI versatile tine cultivator have tines arranged in four rows. The individual tines are sufficiently spaced, both inside the row and between the individual rows. Therefore, The FENIX FO_PROFI offers high throughput even when working in fields with large quantities of crop residues, organic matter (manure, slurry) or when incorporating catch crop.

The FENIX FO_PROFI tine cultivator excels in the low power demands thanks to the convenient layout of the individual tines against the soil that reduces traction resistance. The arrow layout of the tines provides gradual penetration of the individual tines into the soil and excellent processing along the entire machine width.

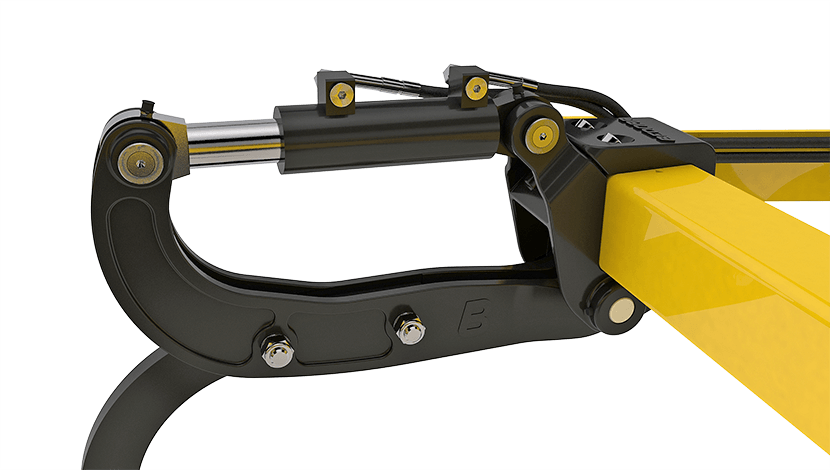

Each tine is mounted (not welded) to the main frame of the FENIX FO_PROFI via solid bracket. The advantage of this solution lies in the high durability of the brackets and the supporting frame. In case of its damage, each bracket can be easily replaced. Each tine firmly preserves its geometry and works within precisely defined limits without oscillations and lift.

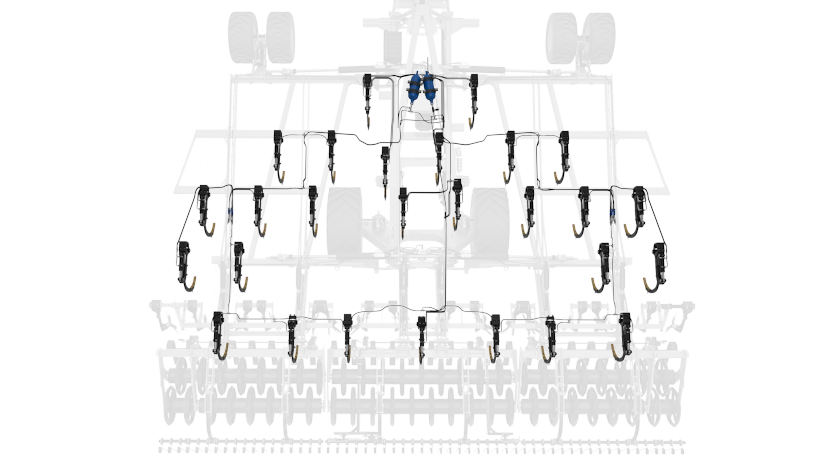

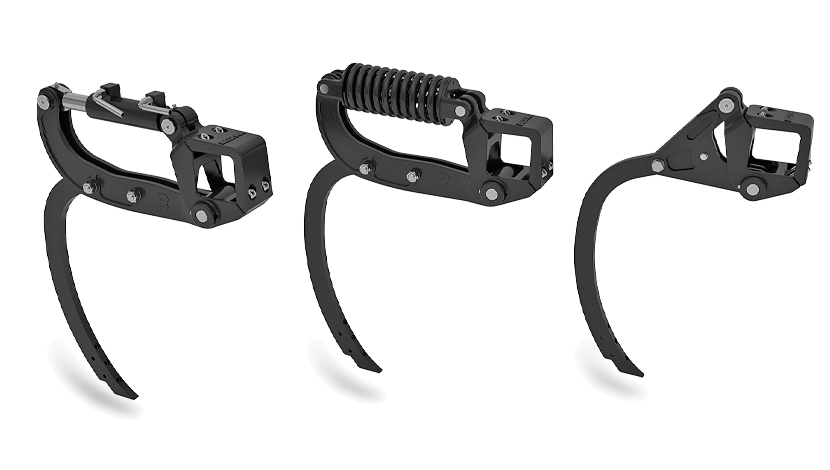

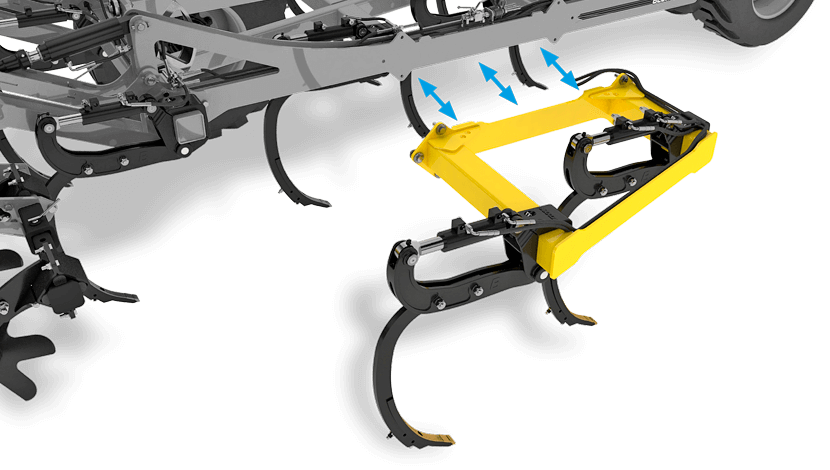

The FENIX FO_PROFI tine cultivator now offers several types of protection: shear bolt protection, double-spring reset tine protection (release force of 500 kg) or comfortable hydraulic reset tine protection (release force of 660 kg).

The integrated axle mounted between the tines enables the machine to work without the rear packer (more tines work behind the transport wheels). When it is wet, the packers can easily be deactivated, and soil is cultivated without consolidation. This advantage can also be used when preparing soil for winter, when it is usually not required or recommended to roll the soil.

FENIX FO_PROFI can be equipped with a variety of working tools depending on the soil conditions or customer’s requirements. Behind the four rows of tines there is a levelling section that can be fitted with levelling discs or spring tines. The levelling section can be operated mechanically using a crank mechanism or hydraulically from the tractor cab.

The FENIX FO_PROFI versatile tine cultivator always offers something extra compared to competing products. In addition to the standard levelling section, the FENIX FO_PROFI can also be fitted with a Crushbar levelling bar in front of the rear packers. The Crushbar levelling bar in front of the rear packers is used to level out any unevenness after the tine section. The packers then only consolidate the soil without levelling it. The levelling bar is controlled via crank mechanism.

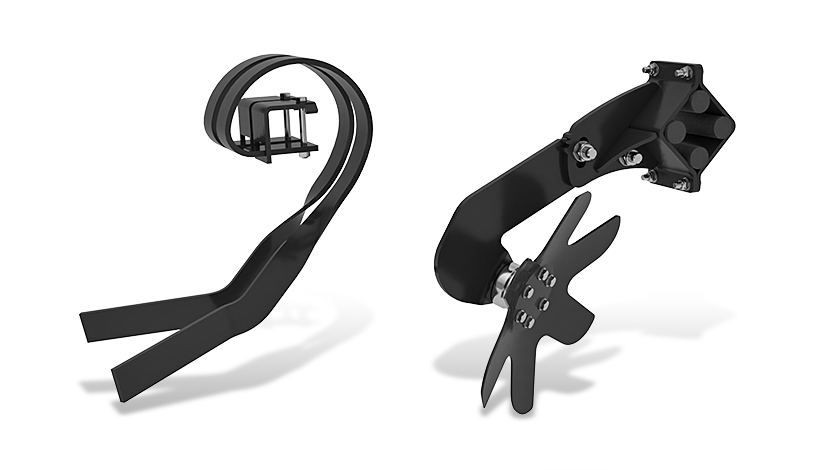

The FENIX FO_PROFI tine cultivator can be equipped with four types of points, which let you adjust the machine for deep loosening or shallow stubble cultivation after harvest. A properly selected point type is also important in terms of the character of the soil to be processed, or the season. You can choose from points with a width of 80 and 60 mm, or LONG LIFE tines with a width of 80 and 40 mm, fitted with carbide plates for higher durability.

The FENIX FO_PROFI tine cultivator can be equipped with support wheels for perfect terrain contouring. They ensure that the field is evenly cultivated at the set working depth along the entire width of the machine.

The rear packers of the versatile FENIX FO_PROFI tine cultivator are mounted via parallel linkage that provides perfect terrain contouring and maintains the set working depth. The rear packers are not a part of the support frame as in other competitive machines.

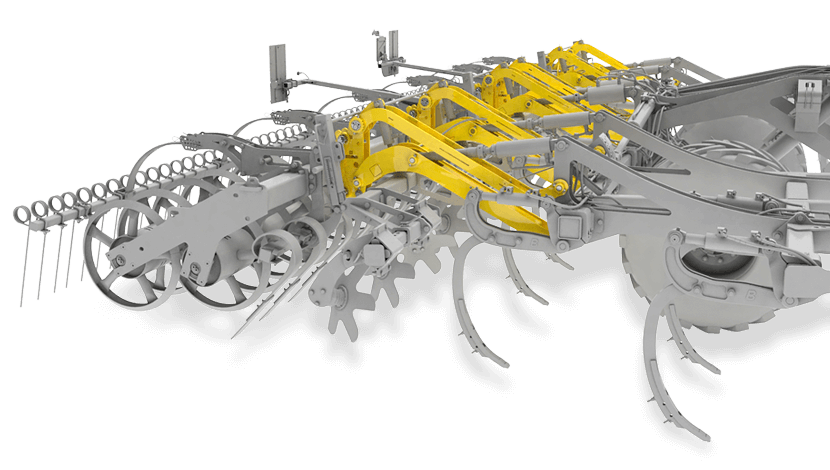

Have you purchased a more powerful tractor or do you need to adjust the machine width to the current conditions and use? The FENIX FO_PROFI models offer the possibility to adjust the working width using the set for assembly/disassembly of the additional side frames.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main parts of the tine cultivator.

They provide terrain contouring and maintain the set working depth along the entire width of the machine.

Ensures excellent undercutting and mixing of crop residues with soil. There are four types of points available to accommodate to the conditions.

Distributes weight evenly and contributes to a higher machine stability.

Each tine is protected against overload by a hydraulic reset protection with a maximum release force of 660 kg. A shear bolt or double spring reset protection is also available.

The levelling section can be fitted with levelling discs or spring tines. This section helps to level the soil surface and crumble large clods before the final surface consolidation.

The Crushbar levelling bar levels the surface before the rear packers. The levelling bar is controlled mechanically via crank mechanism.

Create an ideal fine soil structure and close the soil surface to prevent evaporation.

Distributes and finishes surface levelling behind the packers.

“We have been using BEDNAR machines in our company since 2016. One of the first was the FENIX FO 4000 tine cultivator, which has worked several thousand hectares on our farm. Recently, due to the increase in hectarage, we were looking for a machine that would allow us to increase our daily output. The choice fell again to BEDNAR, and this time we opted for a new machine, the FENIX FO 8004 PROFI tine cultivator. The acquisition of this machine has enabled us to increase our daily output from 22 ha to 60 ha. This machine’s versatility is enhanced by the ability to adjust the working width as needed. For deep soil tillage, we can remove the additional side sections and reduce the machine width from 7.9 m to 6.7 m.”

Gospodarstwo Rolne Maciej Sik farm

Poland

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own FENIX FO_PROFI tine cultivator to precisely match your needs.