OMEGA OO_L

3-9 m

120-500 hp

2 800-4 000 l

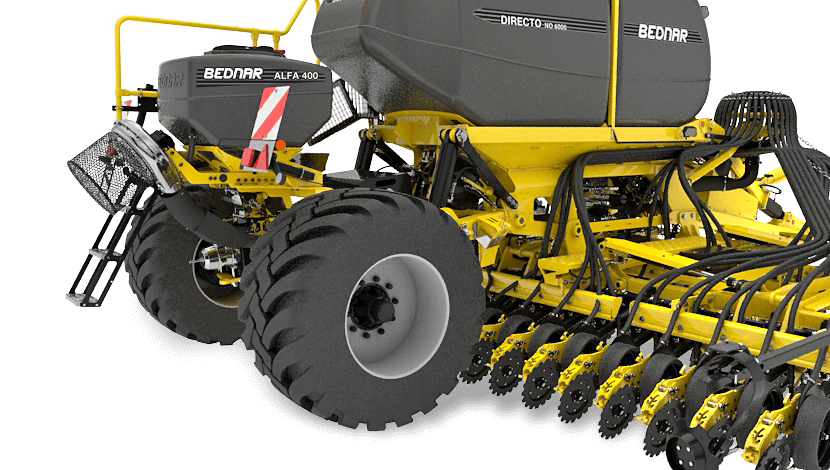

DIRECTO NO is a no-till seed drill with a robust design for direct seeding into stubble, catch crops, tilled or untilled soil. The unique seeding coulter is able to establish crops even in the most difficult conditions of large amounts of crop residues or very dry and difficult to work soils. Up to three crops can be drilled in a single pass, or fertiliser can be placed simultaneously during seeding.

6-8 m

200-360 hp

5000 l

A seed drill for direct drilling and variable establishment of several crops in one pass, including the option of fertilisation.

As part of an experiment with winter wheat of the Butterfly variety, we tested three different seeding methods on fields in Dlouhé Dvory near Hradec Králové. The goal was to compare traditional tillage and subsequent seeding with modern direct seeding technologies, including the DIRECTO NO seed drill. Direct seeding showed significant advantages, particularly in retaining soil moisture during dry periods, which led to a higher number of productive tillers and more stable yields. Beyond agronomic benefits, direct seeding proved to be more economical due to lower fuel consumption, fewer passes over the field, and reduced herbicide costs. This approach offers an effective solution for conditions with large weather fluctuations and contributes to sustainable soil management.

Detailed overview of results

The direct drilling technology completely differs from the used crop establishment methods. Direct drilling does not guarantee increased yields, but it can help you fight soil erosion and degradation. The considerable reduction in the number of passes reduces soil hardening and avoids disrupting soil capillarity. The soil cover of the field guarantees minimum moisture evaporation. The root system helps recover the soil structure.

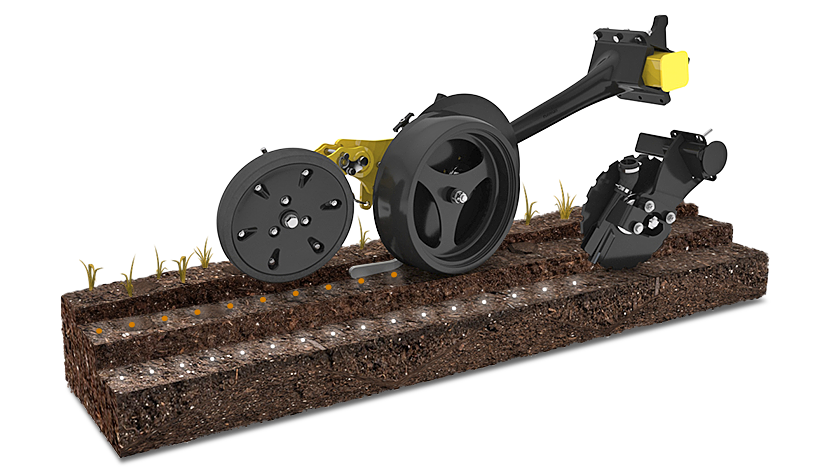

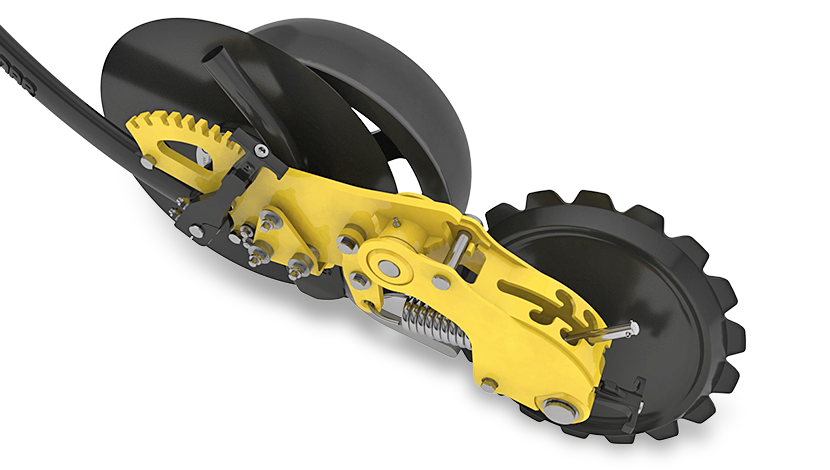

The DIRECT STAR single disc seeding coulter has been developed over several years to be able to work at 100% in almost all seeding conditions directly in stubble, catch crops as well as in tilled soil. Row sapcing 16.7 cm, seeding coulter distance in a row 33.4 cm. The high downforce of 300 kg on the seeding coulter guarantees proper seed placement even in heavy soils. The minimum seeding depth is 2 cm.

For the DIRECTO NO seed drill, we have designed a unique fertiliser coulter that places the fertiliser “under the seed” and slightly to the side. The fertiliser placement depth can be adjusted from 3 to 10 cm. The fertiliser coulters are mounted on a beam. The fertiliser placement depth of the fertiliser coulter is set centrally – there is no need to adjust each disc individually.

The fertiliser coulter places the fertiliser deeper and slightly to the side. This fertilizer deposited by zone ensures plant nutrition in the later stages of growth and supports targeted root development in the lower layers of the topsoil, thus eliminating stress factors, especially a lack of water. Zonal application improves the development of crops especially in autumn and helps the plants to overwinter better.

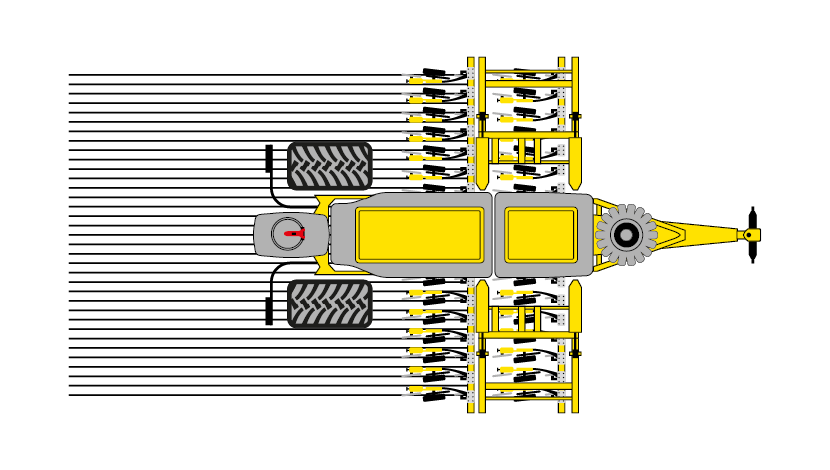

1. The seed is placed in the row together with the fertiliser, the mixing of seed and fertiliser takes place in the pipe.

2. Seeding two types of seeds, mixing of seeds takes place in the pipe.

3. Seeding one type of seed (both chambers are filled with one type of seed).”

*with the possibility of swith-off half of the machine working width in the case of a double distribution head configuration.

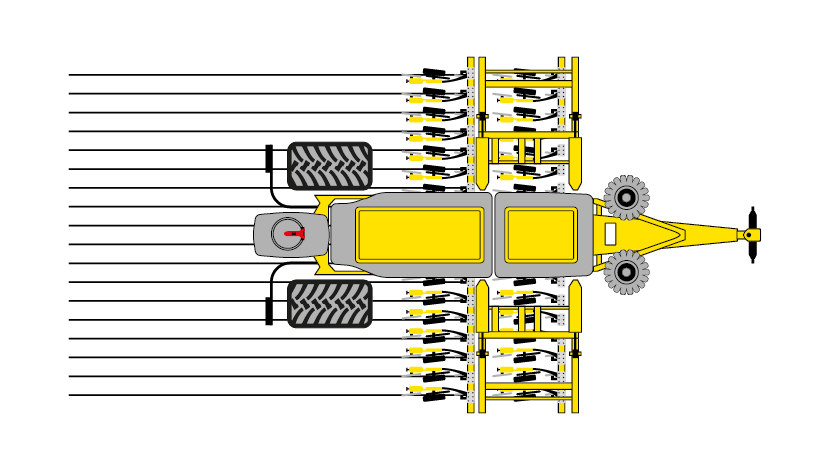

1. The seed is placed in the row together with the fertiliser, the mixing of seed and fertiliser takes place in the pipe.

2. Seeding two types of seed (e.g. seed A deeper in the first row, seed B shallower in the second row).

3. Seeding one type of seed (both chambers are filled with one type of seed).”

*without the possibility of swith-off half of the machine working width.

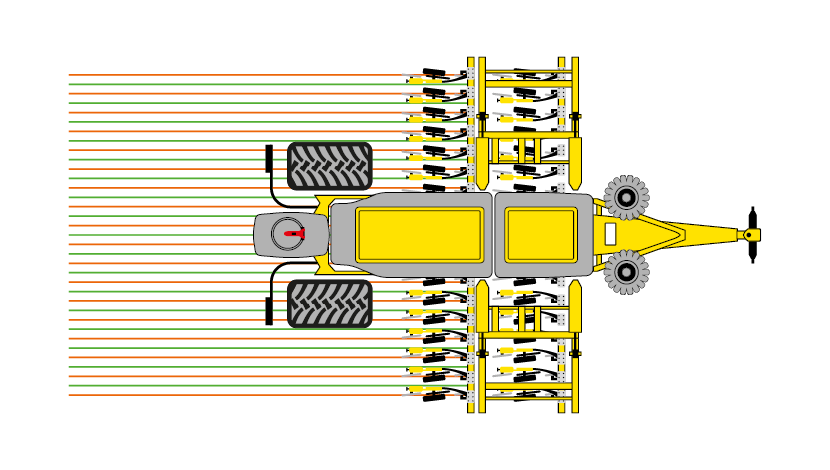

1. The seed is placed in the row with the seed coulter, the fertiliser is placed under the seed and slightly to the side with the fertiliser coulter.

2. Seed A is placed in the row with the seed coulter, seed B is placed deeper under the seed and slightly to the side by the fertiliser coulter.”

*no option of swith-off half of the machine working width.

The DIRECTO NO seed drill can be equipped with two types of closing wheels – notched or smooth. The robust frame of the closing wheel keeps the direction straight. The closing wheel downforce can be adjusted mechanically to close the seed row back, and the angular position of the wheel can be changed (multiple positions – angles). The closing wheel downforce is adjusted on the scale of each seeding coulter. The downforce is created by a tensioned spring. The spring does not release from the holder.

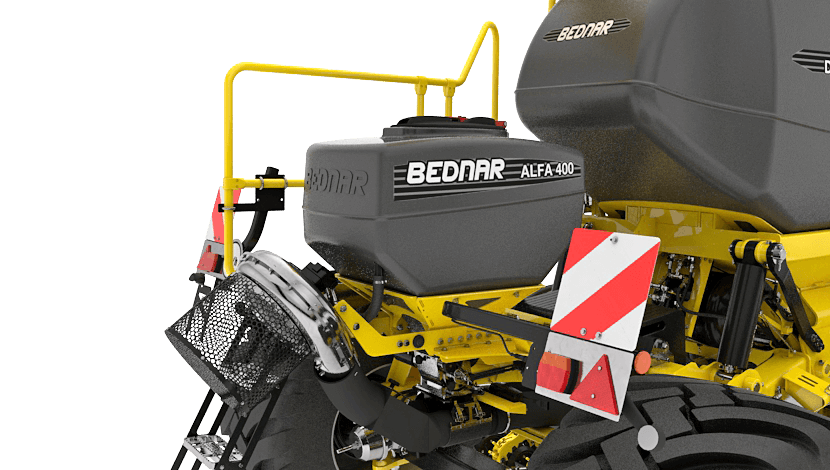

In combination with the ALFA DRILL seeder, it is possible to seed up to three types of seed in a single pass or to apply microgranulate at the same time. The ALFA DRILL 400 seeder provides a hopper capacity of 400 litres. The material from the ALFA DRILL seeder can be directed into the seeding coulters, fertiliser coulters or in a 50:50 ratio.

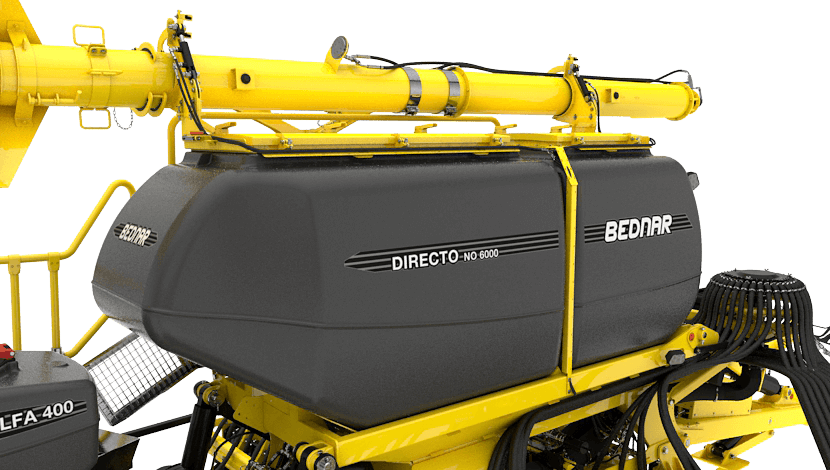

The BEDNAR brand uses a pressurised hopper solution for all its seed drills. Overpressure is created in the hopper thanks to the airtight closure. This technical design allows for dosing large seeding amounts with high precision independent of the seed/fertiliser granule size. DIRECTO NO is equipped with a double-chamber pressurised hopper with a total capacity of 5,000 litres.

In addition to the standard hopper filling, DIRECTO NO also offers filling with the use of a filling auger. The filling auger is a part of the optional equipment for the machine. A suitable solution for filling the seed drill is through the rear dispensing window of the semi-trailer.

Ease of use is a priority for today’s operators. DIRECTO NO is equipped with the new BEDNAR EASY CONTROL software, which guarantees easy and clear operation. The software offers clear, easy and intuitive control of the seed drill. If the seed drill is equipped with an ALFA DRILL 400 seeder, the seeder control is fully integrated into one system (no additional monitor required).

BEDNAR developers designed an application for mobile phones that provides easy and simple calibration of the seed drill from your mobile phone. The mobile application includes a guide that helps with the right selection of the seed metering roller based on the type of seeds/fertiliser, working speed and seeding amount.

The DIRECTO NO seed drill is equipped with large flotation tyres with a dimension of 710/50 R26.5. The large tyres reduce pressure on soil and eliminate tracks when establishing crops in fields with high moisture levels. The seed drill does not exceed the transport width of 3 m.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the seed drill for direct drilling.

Contributes to excellent terrain contouring and easy connection to various types of tractor hitches.

A double-chamber hopper with the total capacity of 5,000 litres. The pressurised hopper offers high dispensing accuracy.

The ALFA DRILL seedert allows seeding another type of seeds or applying microgranulate by mixing the seeds or fertiliser in the pipeline.

The support wheels with mechanical setting stabilise the seed drill. The seed drill works in the plane and the set working depth is maintained.

It is used for comfortable filling of the double-chamber hopper of the seed drill, for example, using the emptying window in the trailer.

Suitable for increasing the weight of the seed drill to ensure quality crop establishment in difficult conditions.

The patented drill coulters with a high down pressure of 300 kg/drill coulter guarantee quality and even placement of seeds in the soil, even in difficult conditions.

The large flotation tyres reduce pressure on soil and prevent the formation of tracks.

The fertiliser coulters places the fertiliser “under the seed” and slightly to the side. The working depth of the fertiliser coulters is adjusted centrally – there is no need to adjust each coulter individually.

DIRECT SEEDING AS A CURRENT TREND

Direct seeding into soil that has not been tilled beforehand is a current trend in establishing both main crop and catch crop. Direct seeding is a response to the ongoing increase in drought and water scarcity. The advantage of direct seeding lies in the elimination of soil moisture evaporation, reducing the risk of erosion, soil overheating, and weed growth. It increases the organic matter volume in the soil and significantly saves time and costs required for seeding.

| DIRECTO NO | NO 6000 | NO 8000 | |

|---|---|---|---|

| Working width | m | 6 | 8 |

| Transport width | m | 3 | 3 |

| Transport length | m | 9,9 | 10,8 |

| Transport height | m | 4 | 4 |

| Drill coulter spacing | cm | 16,7 | 16,7 |

| Number of drill coulters | pcs | 36 | 48 |

| Drill coulter down pressure | kg | 300 | 300 |

| Fertilisation disc spacing | cm | 16,7 | 16,7 |

| Number of fertilisation discs | pcs | 36 | 48 |

| Drill coulters – diameter | cm | 45 | 45 |

| Closing wheels – diameter | cm | 38 | 38 |

| Guiding wheels – diameter | cm | 40 | 40 |

| Hopper volume | l | 5000 | 5000 |

| Hopper chamber ratio | 60:40 | 60:40 | |

| Filling height | m | 3,2 | 3,2 |

| Volume of BEDNAR ALFA DRILL hopper* | l | 400 | 400 |

| Frame type | folding | folding | |

| Power demand* | hp | 200 - 280 | 280 - 360 |

| Hitch type | crossbar cat. III, IV | crossbar cat. III, IV | |

| Tyre size of support wheels | 15/55–17 | 15/55–17 | |

| Transport tyre dimensions | 710/50 R26.5 | 710/50 R26.5 | |

| Max. total weight** | kg | 12150 | 13020 |

* not included in the basic equipment ** according to the machine equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.