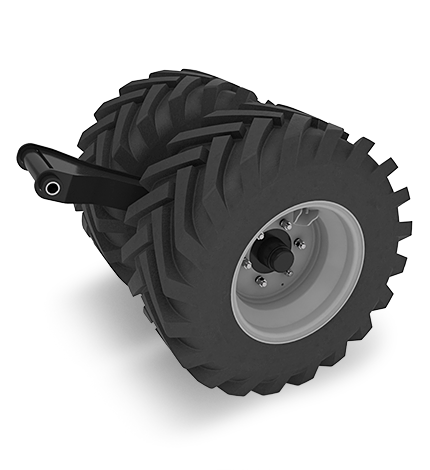

Double front support wheels

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

ATLAS AO_PROFI belongs to the category of heavy compact disc harrow. This robust harrow with a short design is constructed for cutting, mixing with soil, and incorporating large amounts of crop residues and organic matter, even when working in wet conditions. This key advantage of ATLAS AO_PROFI compact disc harrow is due to their robust construction, high frame clearance, distance between individual working sections, and large disc diameter.

6-16 cm

5-7 m

250-400 hp

The ATLAS AO_PROFI product range belongs to the range of heavy disc harrows, which are suitable for processing large amounts of crop residues.

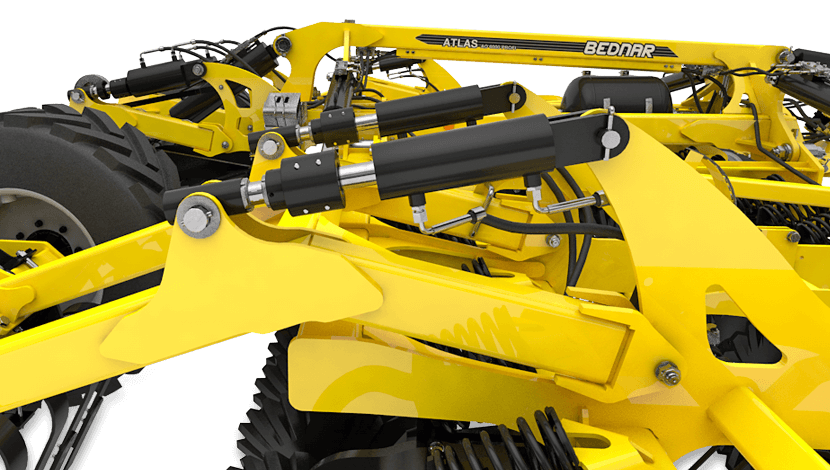

ATLAS AO_PROFI models have disc sections arranged in an “X” pattern. This innovative technical solution eliminates lateral movement of the machine, known as drifting. As a result, the compact disc harrow precisely follows the tractor’s tracks. The central double disc reduces the risk of ridges forming.

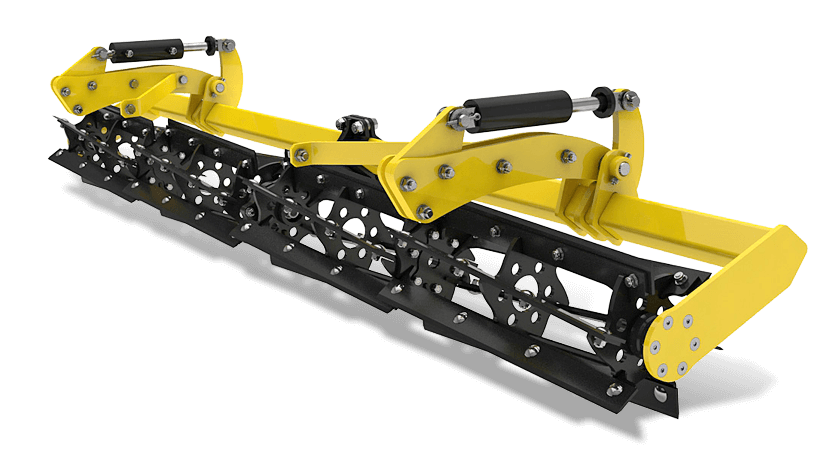

The double row arrangement of the rear packers provides greater stability at high speeds than a single row, and also eliminates the gap that occurs with disc harrows with two rollers in a single row. The integrated axle ensures even weight distribution and eliminates swaying of the machine. It also makes transport safer and reduces the turning radius of the tractor with the cultivator at the headland.

The ATLAS AO_PROFI is a heavy-duty compact disc harrow. Its robust build gives high machine weight and even downforce across the disc section, securing consistent penetration even in dry soils. The same robustness also ensures excellent incorporation of large volumes of residue.

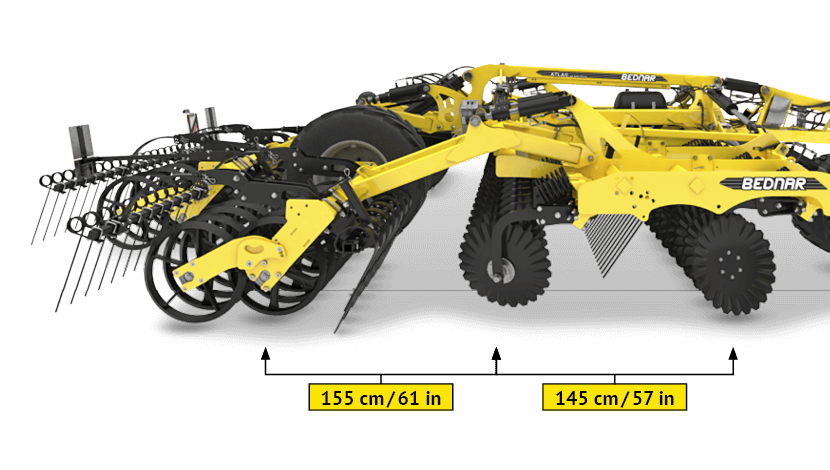

The heavy ATLAS AO_PROFI compact disc harrow are designed to process large amounts of crop residues, catch crops, and other organic material (slurry, manure). For trouble-free operation and to eliminate possible clogging of the machine, even when working in wet conditions, this product range offers sufficient distance between the individual working sections. The in-front of and rear rows of the disc section are more than 145 centimeters apart, and the distance between the discs and the rear axle of the packer is up to 145 cm. The frame clearance is approximately 70 centimeters, ensuring trouble-free passage.

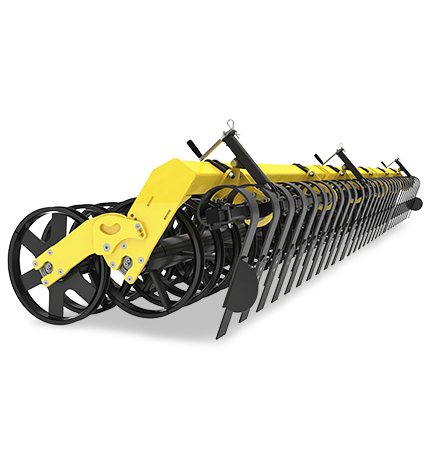

The ATLAS AO_PROFI compact disc harrow can be equipped with a Trash Cutter cutting roller in front, which is ideal for cutting plant residues and tough stalks. The chopped crop residues decompose better in the soil and facilitate subsequent tillage, during which the machine does not clog.

ATLAS AO_PROFI compact disc harrows are equipped with easy working depth adjustment without the use of spacers even in the basic version. The working depth is adjusted hydraulically on the rear rollers and front support wheels.

ATLAS AO_PROFI can be equipped with electro-hydraulic machine control upon request. The proprietary BEDNAR EASY CONTROL software allows for fully automatic control of the compact disc harrow and easy and simple adjustment of the working depth from the comfort of the cab using a dedicated monitor or by connecting to the tractor monitor via an ISOBUS cable.

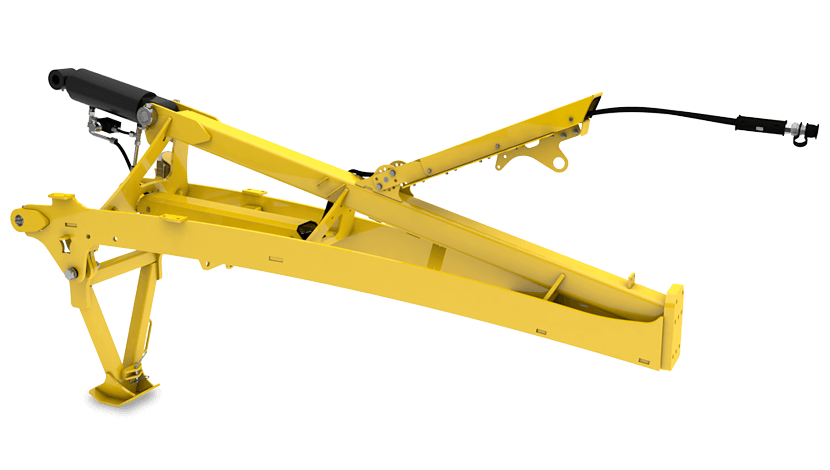

The ATLAS AO_PROFI compact disc harrow is equipped with a hydraulic drawbar. We use this technical solution because it facilitates connection to the tractor and, above all, improves the quality of work, as the disc harrow perfectly follows the unevenness of the terrain.

The ATLAS AO_PROFI compact disc harrow can be equipped with the BEDNAR ALFA DRILL seeder for seeding catch crops and small-seeded plants during stubble cultivation in a single pass. The savings in time and fuel are significant in this case. The sowing unit has a hopper capacity of 400 liters.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise overview of the main working parts of the disc cultivator.

A hydraulically adjustable drawbar contributes to perfect terrain contouring and levelling any unevenness.

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

Disc section with notched or aggressive discs, with a diameter of 620 × 6 mm and spring reset disc arm protection.

It ensures even weight distribution of the machine, contributes to greater stability, and reduces the risk of machine swaying at higher working speeds. Another advantage is the reduction of turning radii at headlands and high maneuverability even in rough terrain.

A wide range of rear packers allows the machine to be adapted to specific conditions. The arrangement of packers in two rows prevents the machine from rocking during operation. Packers help to reseal the surface and thus prevent soil moisture from evaporating.

It perfectly levels any minor unevenness and evenly spreads clods along the entire machine width.

“I like the work with the harrow, which is why we chose it. I see the main advantages of the ATLAS AO_PROFI machine for us in the high throughput of the frame, which is necessary due to the large amount of crop residues. From a user’s point of view, I also really like the spring reset arm protection of each disc and the integrated axle in the middle of the machine. This makes transport safe when crossing fields, and I can turn beautifully with the cultivator in corners. The aggressive discs with a diameter of 620 × 6 mm do a great job.”

Hak, co-owner, PLOTIŠŤSKÁ ZELENINA – HAK s.r.o., (district of Hradec Králové, CZ)

We know that everyone has different requirements for machine equipment and its intended use. That is why we allow you to customize your ATLAS AO_PROFI compact disc harrow exactly as you require.

The levelling bar, placed in front of the rear double packers is used for levelling off any unevenness after the previous section. The packers only consolidate soil, they do not level it. The outcome is a perfectly levelled field.