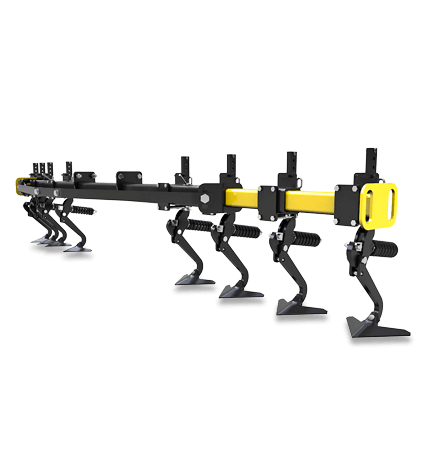

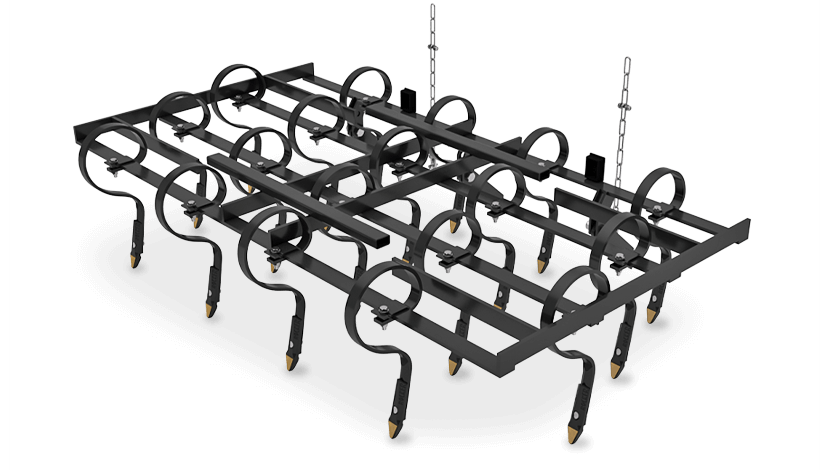

Telescopic track eradicators

A track eradicator with an adjustable width. It is used for loosening hardened tracks created by the towing vehicle.

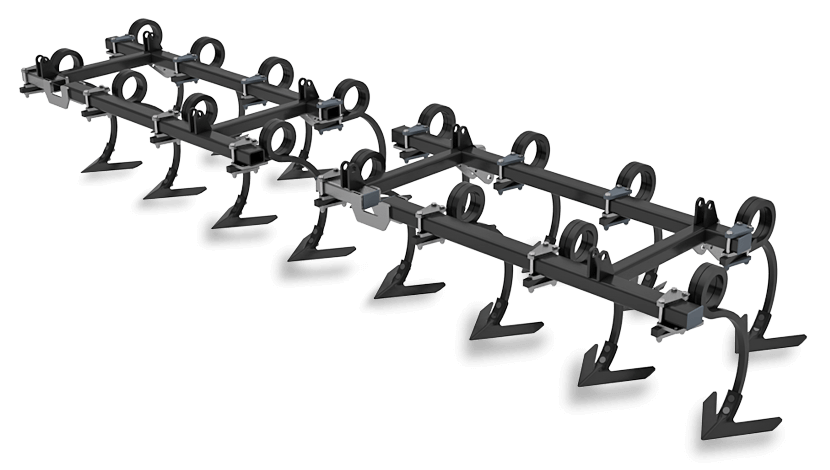

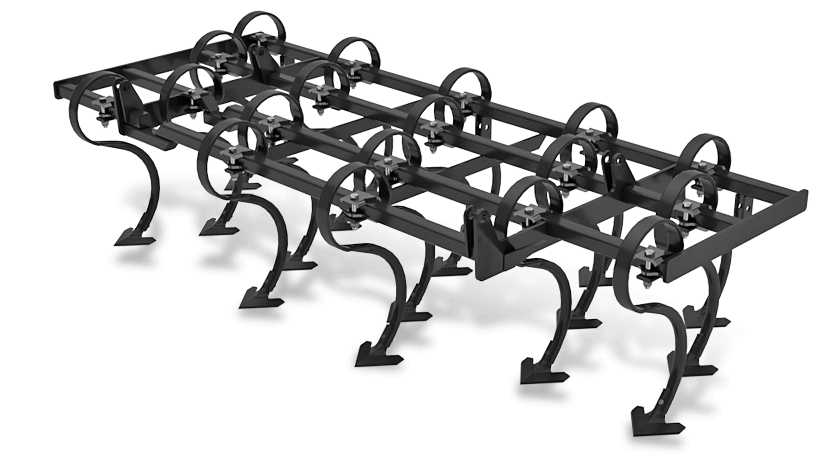

Using seedbed cultivators for seedbed preparation is still a popular practice. In the segment of seedbed cultivators with a working width of 13′ 1″ to 26′ 3″, we offer the well-proven design of the SWIFTER SO_F implement. SWIFTER SO_F has very low demands on the tractor towing power thanks to its light, but highly durable frame. In one pass, it can create an even seedbed, important for even emergence of crop, with a unique combination of up to eight operations. SWIFTER SO_F is a cultivator that can be used in any season because it is easily adjusted to the conditions thanks to the exchangeable working parts.

A seedbed cultivator with a standard design suitable for traditional tillage, as well as minimimum tillage systems.

Combining several operations into one means fewer passes through the field and lower costs of tillage. The front levelling bar or leveller perfectly levels off any unevenness. The front crumbling roller crumbles the clods. The main working section undercuts, aerates and warms up the soil layer. The final clod crumbling is provided by various types of rollers in combination with other equipment behind the rollers.

A sweep working section (summer and fall seedbed preparation – winter cereals, canola)

This working section can be used for summer and fall preparation when soil needs to be loosened, undercut and mixed after the previous harvest. The 10.5″ sweeps in two overlapping ranks undercut the soil profile along the entire implement width, creating a firm bottom. At the same time, soil is aggressively processed thanks to the working angle of the sweeps, creating a loosening top layer. Each sweep is mounted on a flexible shank that provides a 3D effect (horizontal and vertical movement) which protects the sweep from damage.

SB sweep section with spring sweeps (spring seedbed preparation – sugar beet)

The section is especially suitable for spring cultivation before seeding sugar beet where it is required to adequately manage spring moisture, but still prepare a precise seedbed. The sweep angle does not mix soil vertically, but the soil is still undercut in the whole area thanks to the overlapping sweeps that are 6.7″ wide. Another benefit is the reduced demand on the tractor.

Gamma-point working section (spring seedbed preparation – spring cereals, corn)

This section is suitable for early spring operations, such as required before seeding barley. The four ranks of gamma points at a negative angle aerate and warm up soil without bringing wet particles to the surface, which preserves winter moisture. It is important for a fast start of growth of spring crop. The spring-loading of each tine enables working at high speed. The gamma points for this section are also available in the LONG LIFE version.

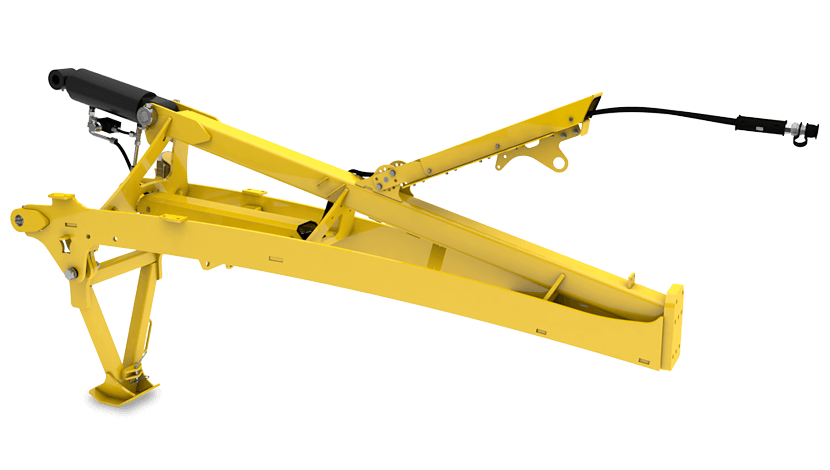

The basic model of SWIFTER SO_F is equipped with a hydraulically adjustable drawbar that enables the implement to perfectly contour the terrain when working in the floating position. The field is then evenly cultivated, resulting in high-precision work.

The side frames with individual working sections are suspended on a robust spacious frame. The supporting frame has a higher durability because the weight of side frame is evenly distributed. The sufficiently dimensioned axle, providing safe transport of the implement, also helps.

The front hydraulic Crushbar levelling bar allows the operator to ideally adjust its working angle according to the field conditions in the comfort of the cabin. When compared with a mechanically controlled leveller, it is possible to achieve savings of up to 0.1 gallons of diesel per acre.

The design of the SWIFTER SO_F cultivator enables turning the implement at the headland without having to lift the working sections. Even so, we recommend turning on the headland with slightly excavated working sections and a larger turning radius.

Do not hesitate to contact us or find the dealer for your area.

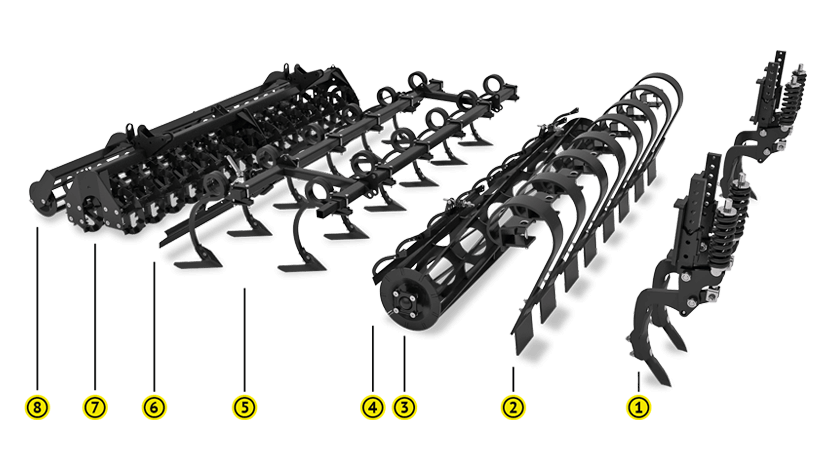

Contact us Find a dealerA concise summary of the main working tools of the seedbed cultivator.

A hydraulically adjustable drawbar contributes to perfect terrain tracing and levelling any unevenness.

The hydraulically controlled Crushbar is used for levelling unevenness and breaking the rough furrow.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 ranks of sweeps/ 4 ranks of gamma points / 2 ranks of SB sweeps) as needed for seedbed preparation for the crop.

It levels off the soil surface after the sweep or gamma-point section.

The dual ranks of crosskill rollers contribute to perfect crumbling of clods created by the sweep or gamma-point section.

The finish roller creates a fine soil structure and completes the entire operation.

“We were maximally satisfied with the SWIFTER cultivator all the time. We noticed how well it prepares soil before seeding when we purchased the first implement. When I compare the current implement with the previous ones, I have to say that you’ve tuned the SWIFTER to the very last detail and eliminated even the minor deficiencies. A completely re-done and improved frame, better configuration of the levelling bars before the rear rollers or minor things such as the compression spring on the rear crosskill rollers; all of that is noticeable.”

Lukas Dosoudil, Agronomist, AGRA Chvalkovice

Olomouc, Czech Republic

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTER SO_F seedbed cultivator to precisely match your needs.