Flotation caster wheels

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.

The SWIFTERDISC XE 18400 MEGA compact disc harrow ranks among the most powerful harrows in the world. 769.36 hectares. This is the area that was processed with the BEDNAR SWIFTERDISC XE 18400 MEGA compact disc harrow during continuous 24-hour operation (23 hours and 36 minutes of pure working time).

2-14 cm

14,4 -18,4 m

400-650 hp

SWIFTEDISC XE_MEGA is a unique series of extra-wide working width compact disc harrows of classic design with the largest working width on the market.

In July 2023, the SWIFTERDISC XE 18400 MEGA compact disc harrow managed to process an incredible 769.36 hectares during continuous 24-hour operation. The event, called “24 HOURS RECORD,” took place in Romania.

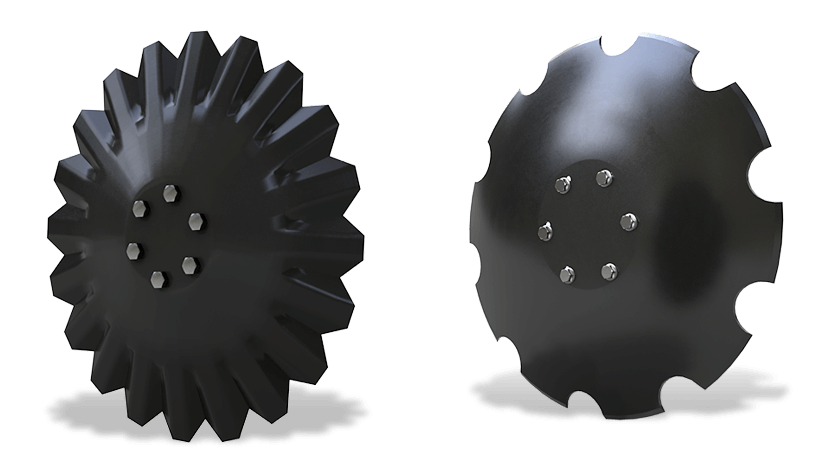

Stubble cultivation is one of the most important operations. According to proper agrotechnical procedures, it should be performed as soon as possible after harvesting. For this operation, the SWIFTERDISC XE_MEGA can be equipped with notched discs or aggressive discs with a diameter of 520 × 5 / 560 × 5 mm, which ensure excellent cutting, soil mixing, and incorporation of crop residues. The rear packers then consolidate and close the worked soil profile for even weed and volunteer emergence.

Even the wide working width SWIFTERDISC XE_MEGA models have disc sections arranged in an “X” pattern. This innovative technical solution eliminates sideways movement of the machine, known as drifting. As a result, the compact disc harrow precisely follows the tractor’s line. The center disc eliminates the risk of ridges forming.

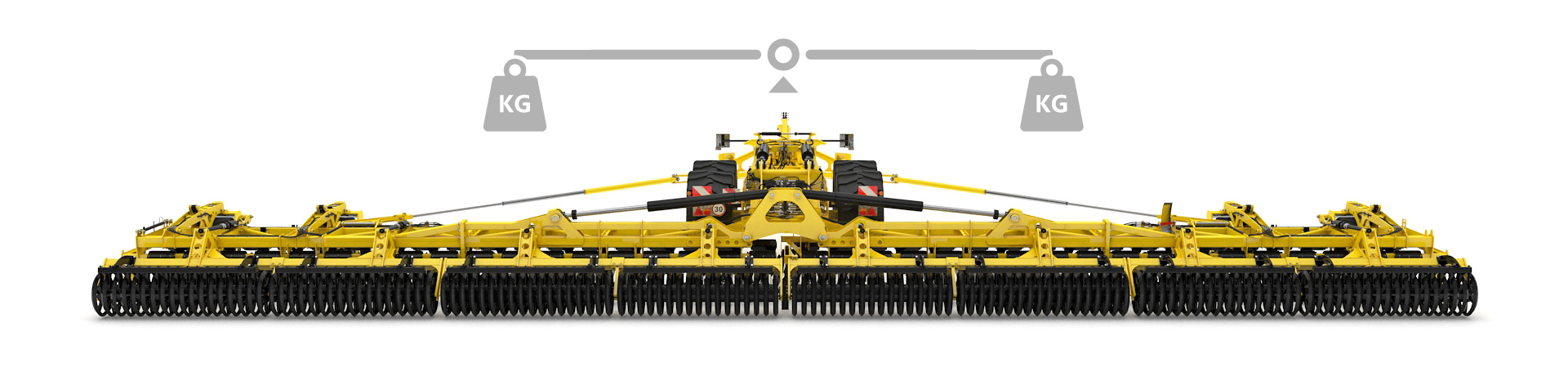

The basis for high-quality tillage is adherence to the set working depth for uniform tillage of the soil profile. SWIFTERDISC XE_MEGA compact disc harrows have the same pressure on the discs across the entire working width of the machine, even at the edges of the harrow, thanks to the forward-mounted tandem axle and the concept of two folding, undivided side frames. The machine’s design reduces the number of hydraulic cylinders where pressure loss to the side frames could occur. This solution also contributes to a low number of lubrication points, reduces overall machine wear, and simplifies machine handling both in the field and during transport.

The SWIFTERDISC XE_MEGA wide working width compact disc harrow is very maneuverable even at its maximum working width of 18.4 metres, even at headlands. The machine turns on the headland on rear rollers, front support wheels, and a transport axle. This solution eliminates negative load on the hitch and lightens the tractor when the machine is in the headland position.

The CTF (controlled traffic farming) system is used to eliminate soil compaction and optimize the movement of individual units. When performing work operations, individual units move across the land in a given working width grid (6, 12, 18, 24 m, etc.), which prevents uneven consolidation across the entire land and instead creates track lines that are then easily subsoiled.

Even with a maximum working width of 18.4 meters, the SWIFTERDISC XE_MEGA compact disc harrow is very compact during transport, as it does not exceed a transport width of 3 metres. These parameters are achieved primarily by folding the side frames forward onto the drawbar. The tandem transport axle with wide-profile tyres ensures a smooth ride.

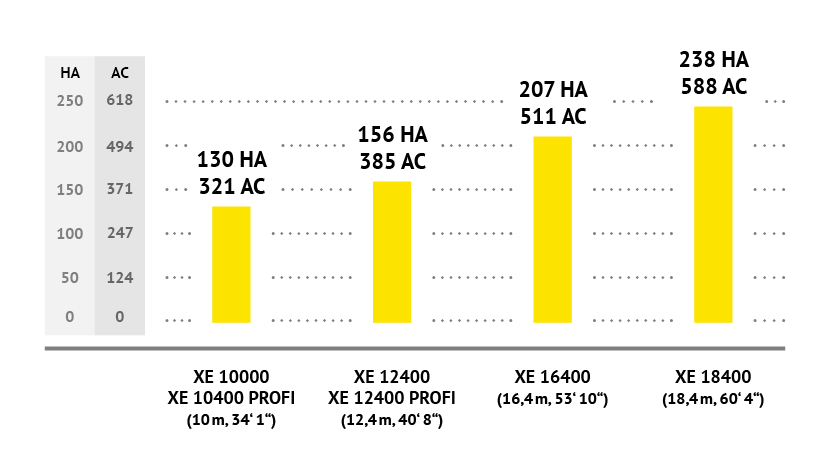

The SWIFTERDISC XE_MEGA compact disc harrow is designed for coupling with the most powerful tractors on the market, such as four-wheel drive tractors. Combined with a working width of 18.4 meters, high engine power, and working speed, these connections enable high daily outputs of up to 230 hours.

SWIFTERDISC wide working width compact disc harrows are designed for coupling with the most powerful tractors on the market. Thanks to their sophisticated design and high working speed, these harrows offer maximum daily output.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerProvides safe turning at headlands and enables the forward side frame folding.

Provide excellent contouring of the terrain and maintain the set depth across the full working width.

Disc section with notched or aggressive discs, with a diameter of 520 / 560 × 5 mm.

Provides ideal distribution of the machine weight and contributes to precise adherence to the set working depth thanks to the identical pressure on the disc section.

The wide range of rear packers make it possible to adjust the machine to any conditions. Two-row packer layout prevents machine swaying during work.

Provide excellent terrain contouring and maintain the set working depth along the entire width of the machine.