Cage roller

The screw-shaped cage roller formed by rods crumbles the clods on the field surface.

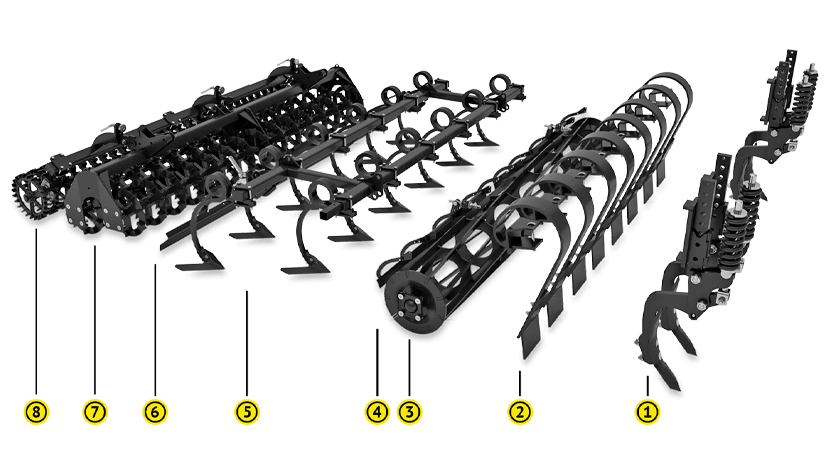

Quality small-seed crop establishment requires a perfectly prepared seedbed. SWIFTER SO_PROFI is a modern seedbed cultivator that is able to prepare the field in one pass, thanks to the combination of up to eight operations in one pass. The innovative design of side frame spring-loading lets you work with the cultivator at higher speed, achieving a better crumbling and levelling effect. SWIFTER SO_PROFI is a cultivator that can be used in any season because it is easily adjusted to the conditions thanks to the exchangeable working parts.

2-12 cm

5-6 m

140-230 hp

A professional cultivator with a standard design suitable for traditional seedbed preparation, as well as minimimum tillage systems.

SWIFTER SO_PROFI is the top machine in semi-mounted seedbed cultivators available on the market. We have developed some interesting devices for the SWIFTER cultivator over the course of time. For example, there is the spring-loading of the side frames with a coil spring, the option of using a third crosskill roller after the rear rollers, or the front slatted roller with a replaceable pin.

Combining several operations into one means fewer passes over the field and lower costs of seedbed preparation. The front levelling bar or leveller perfectly levels off any unevenness. The front crumbling roller crumbles the clods. The tine section undercuts, aerates and warms up the soil layer. The machine can be equipped with a third crosskill roller with a large specific weight installed after the double crosskill rollers to achieve the maximum crumbling effect and fine structure of the cultivated field.

The SWIFTER SO_PROFI cultivator has both side frames spring-loaded with a coil spring. This interesting design contributes to even weight distribution and above all absorbs shocks that are not transferred to the central supporting frame. The spring-loading of the side frames thus contributes to achieving higher working speed and machine durability, together with maintaining a constant working depth. Moreover, the spring-loading of the frames does not require any adjustments – it is a user-friendly and a trouble-free design.

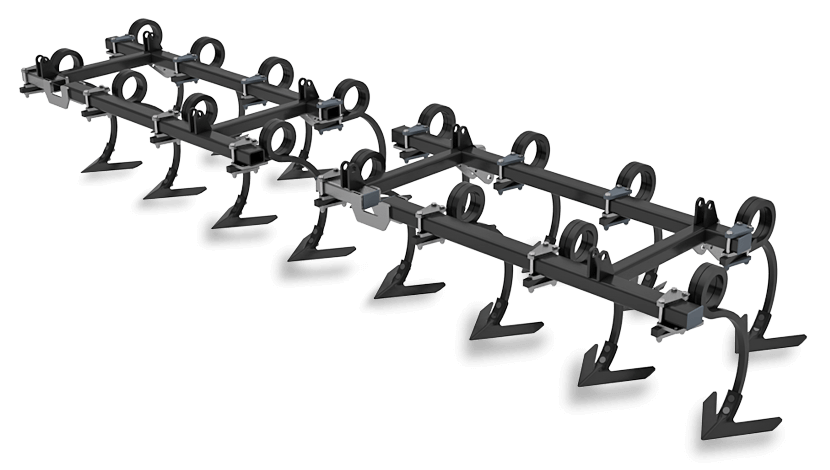

A share section

This working section can be used for summer and autumn preparation when soil needs to be loosened, undercut and mixed after the previous harvest. The 270 mm shares in two overlapping rows undercut the soil profile along the entire machine width, creating a firm bottom. At the same time, soil is aggressively processed thanks to the working angle of the shares, creating a loosening top layer. Each share is mounted on a flexible tine that provides a 3D effect (horizontal and vertical movement) which protects the share from damage.

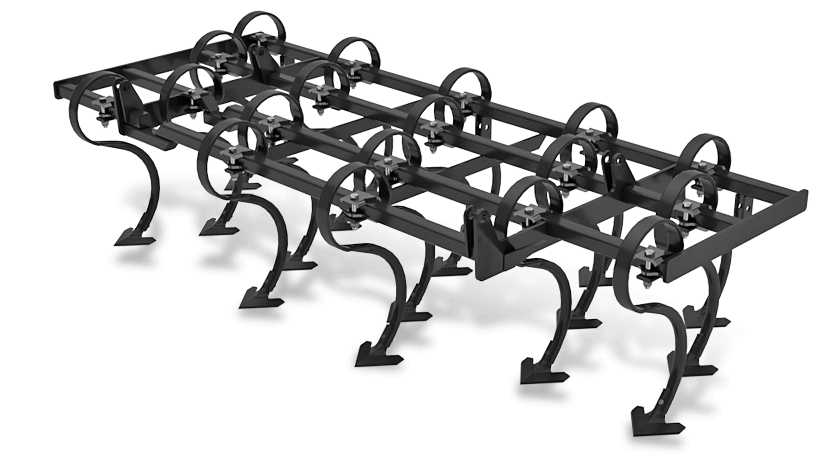

SB section

The section is especially suitable for spring cultivation before of planting sugar beet where it is required to adequately manage spring moisture, but still prepare a precise seedbed. The share angle does not mix soil vertically, but the soil is still undercut over the whole area thanks to the overlapping shares that are 170 mm wide. Another benefit is the reduced demand on the towing vehicle power.

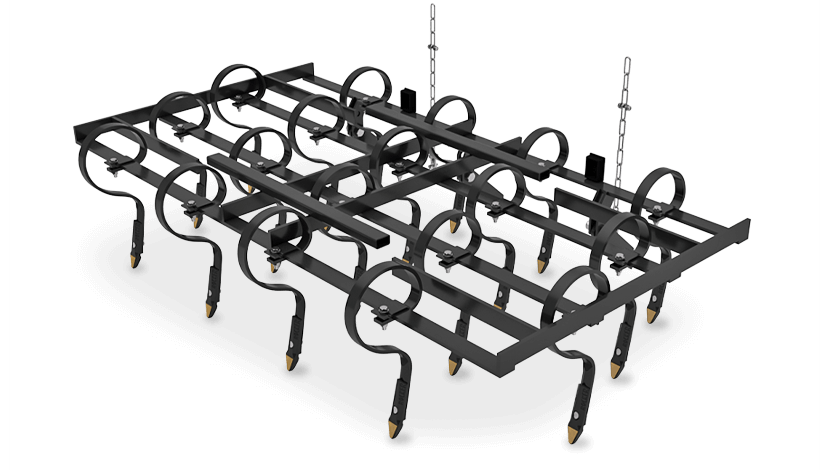

Gamma section

This section is suitable for early spring operations, such as before seeding barley. The four rows of gamma points at a negative angle aerate and warm up soil without bringing wet particles to the surface, which preserves winter moisture. It is important for a fast start of growth of spring crop. The spring-loading of each tine enables working at high speed. The gamma points for this section are also available in the LONG LIFE version.

When compared with competitive machines, SWIFTER SO_PROFI offers the widest range of rear equipment, including the levelling bar, tine harrow, finish roller or the third crosskill roller. The last crosskill roller has a diameter of 350 mm and creates the perfect soil structure, namely in difficult conditions.

The side frames with working sections are suspended on a robust spacious frame. The supporting frame has a higher durability because the weight of the side frame is evenly distributed. The placement of the transport axle also contributes to that as it has a low centre of gravity, unlike competitive machines.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main parts of the seedbed cultivator.

A hydraulically adjustable drawbar contributes to perfect terrain contouring and levelling any unevenness.

The hydraulically controlled Crushbar is used for levelling unevenness and breaking the rough furrow.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 rows of shares/ 4 rows of gamma points / 2 rows of SB shares) as needed for seedbed preparation for the crop.

The double-row crosskill rollers contribute to perfect crumbling of clods created by the share or gamma-point section.

The third finish roller creates the final fine soil structure and completes the entire operation with consolidation.

“We stopped using the original cultivator a long time ago because it created a lot of clods, and we started using a SWIFTER. Moreover, when we had a SWIFTER here for testing, nothing else worked for the clods because it was extremely dry. The soil here is rocky and it is far from light in many places. A great advantage is that I do not have to level the field twice in these extreme conditions. The machine perfectly levels the field at a speed of 12 km/h, and there is no need to do another pass. I can do almost 45 ha per day.”

Jiří Houdek,

Machine operator, AGRASPOL Předmíř, a. s. (district of Strakonice, CZ)

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTER SO_PROFI seedbed cultivator to precisely match your needs.