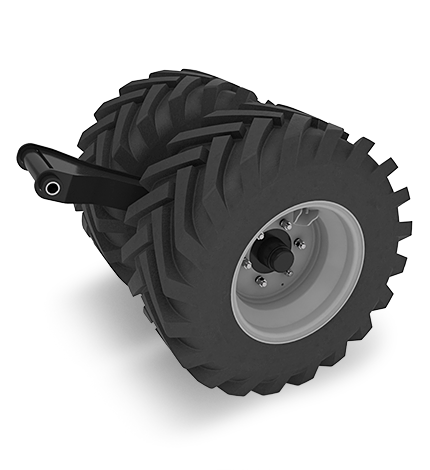

Dual gauge wheels

Provide excellent terrain contouring and maintain the set working depth across the entire implement width.

The SWIFTERDISC XO_PROFI is a new model line of compact speed disc in the BEDNAR range. The PROFI label brings customers a whole series of advantages in the form of new technical designs. The SWIFTERDISC XO_PROFI model excels at high working speed, high-quality workmanship, and excellent quality of work.

0.5"-5.5" in

20' 6" -23' 9" ft

250-350 hp

The SWIFTERDISC XO_PROFI model line is a professional line of high speed disc with properties suitable for tillage after harvest, as well as for seedbed preparation.

Tillage is one of the most important field operations. According to the proper agricultural procedures, it should be done as soon after harvest as possible. For this operation, SWIFTERDISC XO_PROFI can be equipped with notched or aggressive discs with a diameter of 20″×0.2″ / 22″×0.2″, providing excellent cutting, mixing with soil and incorporation of trash. The rear packers consolidates soil and close the cultivated soil profile to ensure even emergence of weeds and unwanted cereal seeds.

The small blade diameter in combination with the high working speed provide a high circumferential speed of the discs, which leads to excellent crumbling and mixing effect of the blade gang. If you are planning to use the high speed disc for seedbed preparation more frequently, we recommend adding the front Crushbar levelling bar to the SWIFTERDISC XO_PROFI, for levelling unevenness and breaking the rough furrow.

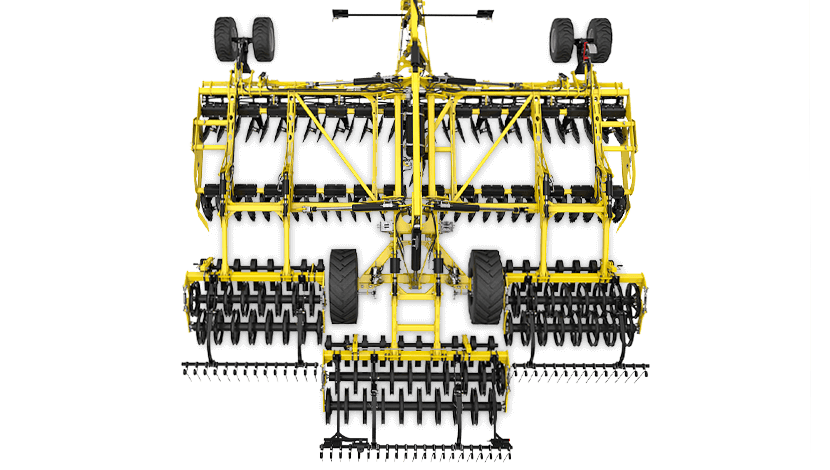

SWIFTERDISC XO_PROFI models have blade gangs arranged in the pattern of an X. This innovative technical design eliminates drifting of the tool to the side. That allows the speed disc to precisely follow the tractor tracks. The central disc reduces the risk of ridge formation.

The two ranks layout of rear packers provides better stability at high speed than a one rank design. The integrated axle ensures even distribution of the implement weight and eliminates its bouncing. Moreover, it ensures safer transport and reduces the turning radius of the tractor with the speed disc at headland.

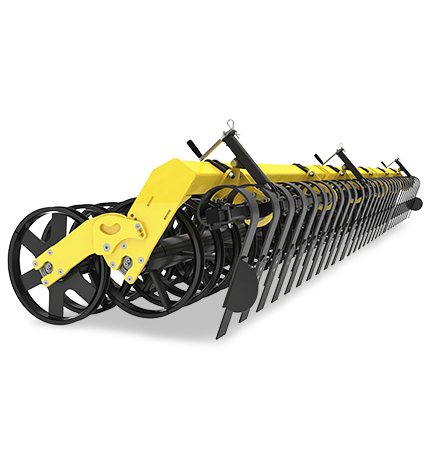

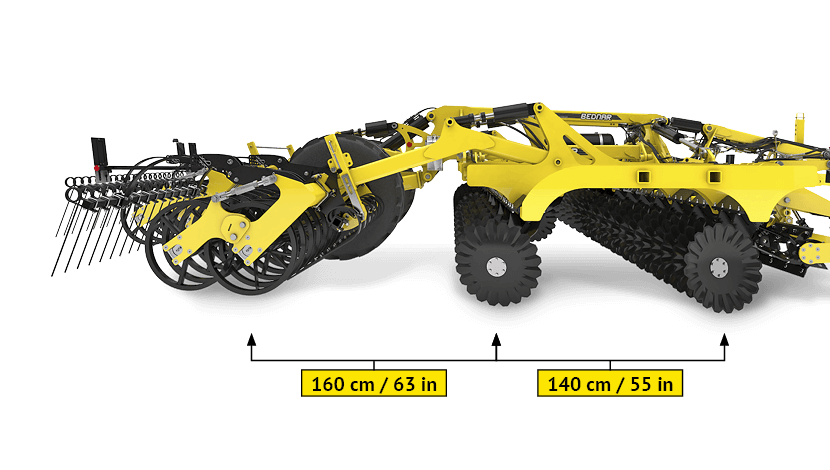

Machines can frequently get clogged while tillage or incorporating larger quantities of trash due to low underframe clearance, or when the working speed is restricted to avoid the formation of waves. In their high speed disc category, SWIFTERDISC XO_PROFI speed discs offer the largest distance between the front and rear rank of the blade gangs 55″, the distance of blades to the rear packer is up to 63″. The underframe clearance of 24″ makes it possible to also incorporate large quantities of organic matter or manure.

SWIFTERDISC XO_PROFI can be equipped with unique tractor track eradicators for perfect loosening of the hardened soil layer. Adding spacers between blade holders can increase the working depth of the discs against other discs in the row by 0.5″ – 1.5″.

The SWIFTERDISC XO_PROFI high speed disc is equipped with a hydraulic drawbar. We use this technical design as it facilitates the connection to the towing vehicle, and above all, improves the quality of work because the speed disc perfectly contours any terrain unevenness.

The SWIFTERDISC XO_PROFI speed disc can be equipped with the Trash Cutter roller in the front, an ideal choice for cutting crop residue and hard stalks. Such cut crop residue decomposes better in soil and facilitates subsequent tillage, preventing machine clogging.

The SWIFTERDISC XO_PROFI high speed disc can be equipped with the BEDNAR ALFA DRILL seeder while in production, for seeding cover crop and small-seed plants during tillage, all in one pass. The time and fuel savings are considerable. The seeder has a capacity of 11 bu.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working tools of the high speed disc

The hydraulically adjustable drawbar contributes to perfect contouring and levelling in uneven terrain

Provide excellent terrain contouring and maintain the set working depth along the entire width of the implement.

Blade gang with notched or aggressive discs, with a diameter of 20.5″ / 22″×0.2″.

Provides even distribution of the implement weight, contributes to better stability, and eliminates the risk of implement bouncing at higher working speed. Another advantage lies in the reduced turning radius at headlands and high manoeuvrability, even in rugged terrain.

A wide range or real rollers and packers make it possible to adjust the machine to the most various conditions. Packers crumble clods and reconsolidate the surface to prevent excess soil water evaporation.

„We started with BEDNAR in 2014 by purchasing a SWIFTERDISC XO 8000 F speed disc. After eight years of effective tillage, we were very satisfied with its performance, particularly with its aggressive blades. Consequently, we upgraded to the XO 7500 PROFI, fully equipped with the ALFA DRILL seeder for our cover crops seedings, large 22” aggressive blades, and the Trash-Cutter roller. We are very pleased with the Trash Cutter’s effectiveness, as it has replaced our rotary cutter, allowing us to do two operations in a single pass.“

Jean-Michel Joppé, Farmer

Somme-Vesle, France

We know that everyone has different requirements for the optional implement equipment and its expected use. Therefore, you can specify your own SWIFTERDISC XO_PROFI speed disc to precisely match your needs.

The leveler in front of the double packers levels any unevenness after the previous section. The packers only consolidate the soil without levelling it. The result is a perfectly level field.