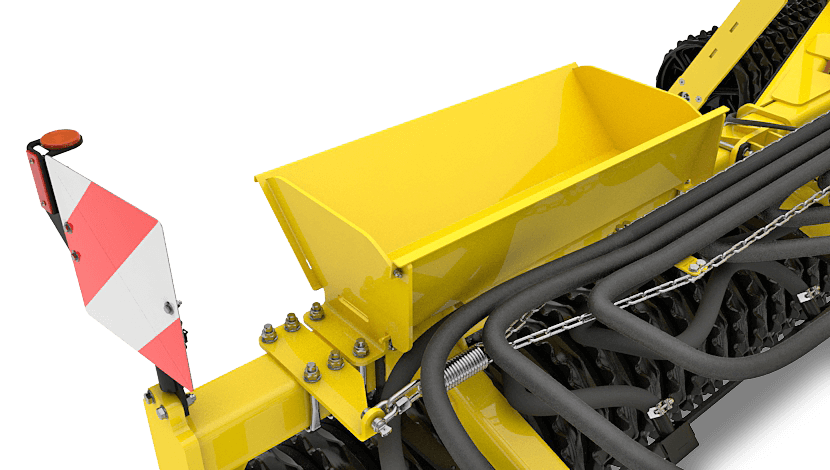

ALFA-DRILL seeder

It is used for seeding catch crops, grasses, or for all-area fertiliser placement. You can do two operations in one pass and reduce your costs.

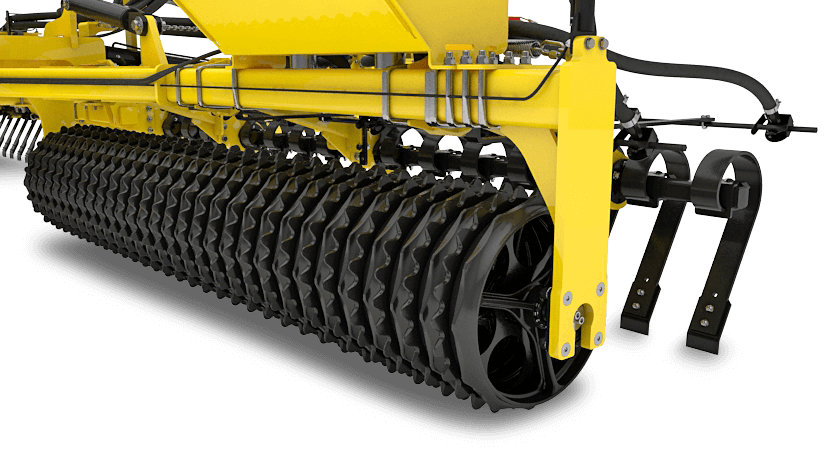

GALAXY GE is a trailed roller with a low center of gravity, high throughput, and the ability to achieve perfect terrain contouring. GALAXY GE rollers are designed for uniform soil profile leveling, effective clod crumbling, and soil reconsolidation.

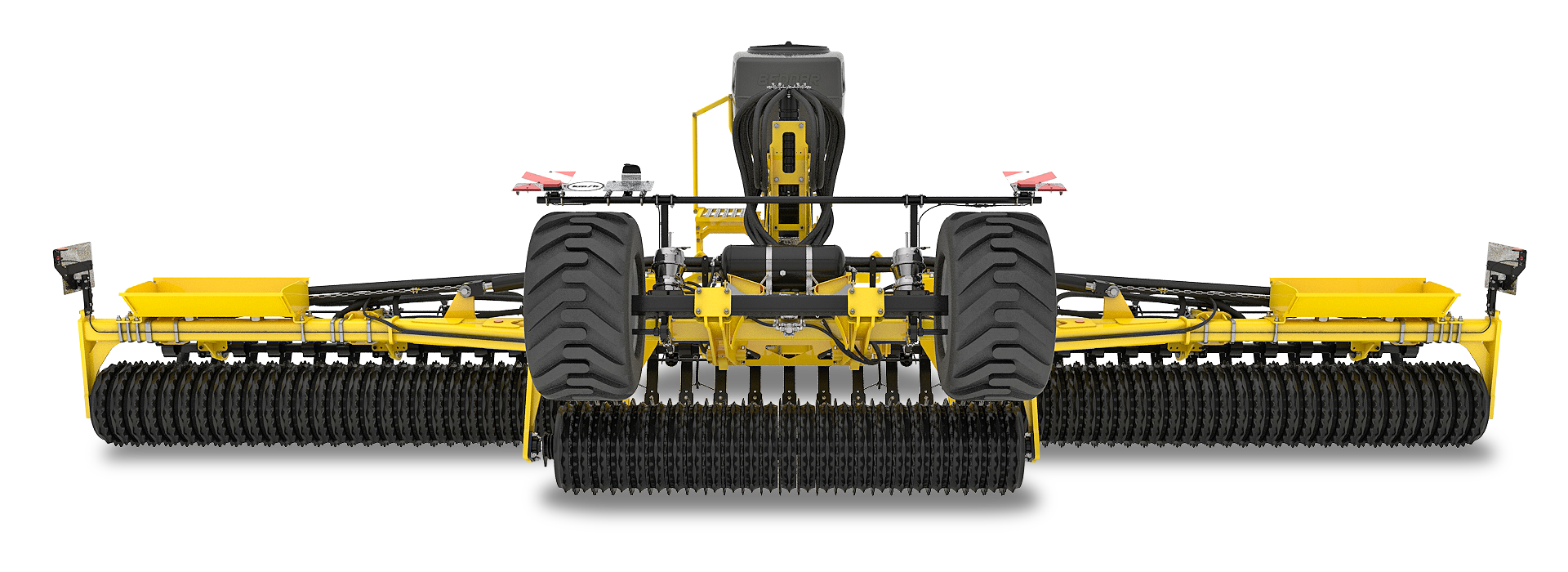

6.3-12.3 m

80-250 hp

GALAXY GE is a trailed roller that provides outstanding clod crumbling and soil reconsolidation. When used in combination with the front Crushbar levelling bar, it also ensures high-quality levelling of the rough furrow.

The GALAXY GE 6300 and 8300 feature a 3-section layout, ideal for medium-sized farms seeking efficiency and consolidation. The new GALAXY GE 12300, with its 5-section frame and 12.3 m working width, ensures optimal terrain contouring and maximum productivity for large-scale operations.

BEDNAR equips GALAXY rollers with rings made of high-strength, quality cast steel in GALAXY GE machines. The cast steel exhibits minimal wear and can endure rocky conditions over the long term.

The individual sections of the GALAXY GE packer overlap and allow for independent surface contouring with a continuous downforce on each working section thanks to the hydraulic system. The hydraulic downforce of the sections guarantees even weight distribution among the individual sections.

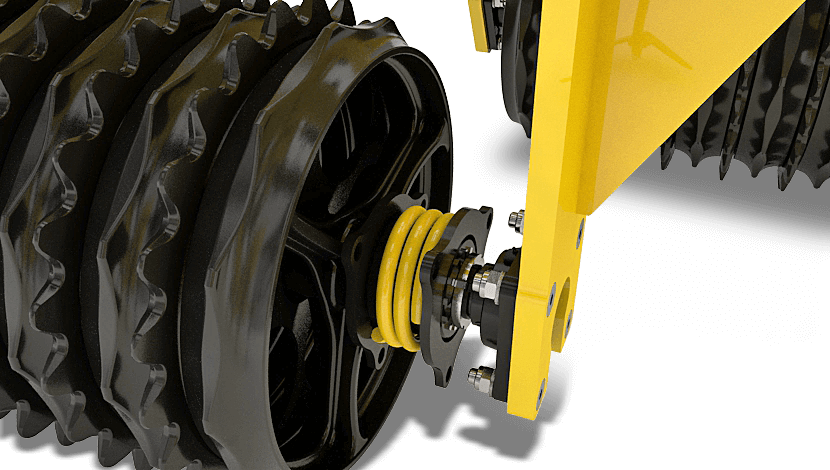

Our experience with rollers has shown that the more hectares the machine has worked, the more slackness there is between the individual rings. BEDNAR has developed a simple and functional solution to address this issue. The spring on the shaft consistently puts pressure to the individual rings, preventing slackness. This design ensures that the rollers can operate for many hectares without maintenance, which is typically necessary to push the rings back into their original position.

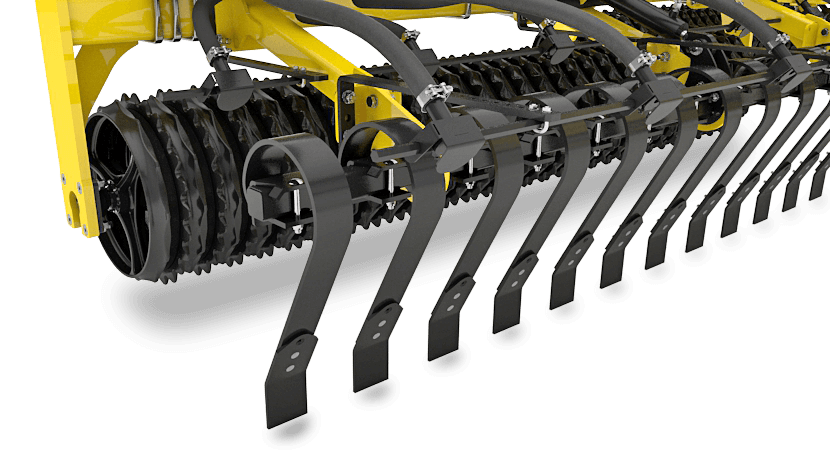

Crushbar is a hydraulically controlled, front levelling bar consisting of broad paddles that work on rods made of quality spring steel. The hydraulic control from the tractor cabin allows the operator to quickly change the aggressiveness of work according to the conditions so that the Crushbar levelling bar can create a levelled field.

The roller can be equipped, on request, with a sufficiently large box for rocks. It eliminates the need to spend time picking up rocks. This job can be performed effectively at the same time.

The BEDNAR ALFA DRILL unit can be installed on the GALAGY GE roller, as standard, for catch crop seeding, fine seeds or for placing microgranulate. In one pass, the soil profile is levelled and seeds are sown or the fertiliser is placed. The seeder has a capacity of 800 litres.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerCan be combined with various types of hitches: 40 mm/51 mm towing eye or k80 ball pin

It increases the durability of the machine and resistance to shocks that affects the frame during work.

The track eradicators are used for loosening hardened tracks created by the tractor.

It is used for rocks and other items found in the field during work.

The hydraulically controlled Crushbar is used for levelling unevenness and breaking the rough furrow.

It is used for placement of microgranulate, fertiliser or various types of seeds in one pass.

The transport axle equipped with brakes and wide tyres increases machine safety and stability during transport.

It increases the durability of the machine and resistance to shocks that affects the frame during work.

The track eradicators are used for loosening hardened tracks created by the towing vehicle.

The hydraulically controlled Crushbar is used for levelling unevenness and breaking the rough furrow.

It is used for placement of microgranulate, fertiliser or various types of seeds in one pass.

The transport axle equipped with brakes and wide tyres increases machine safety and stability during transport.