September

2019

BEDNAR Machines Improve Quality of Work…

The Sebranice Agro Cooperative, ZD Radiměř and ZD Květná use BEDNAR machines in aggregation with the John Deere 9RX 9570 caterpillar tractor. It…

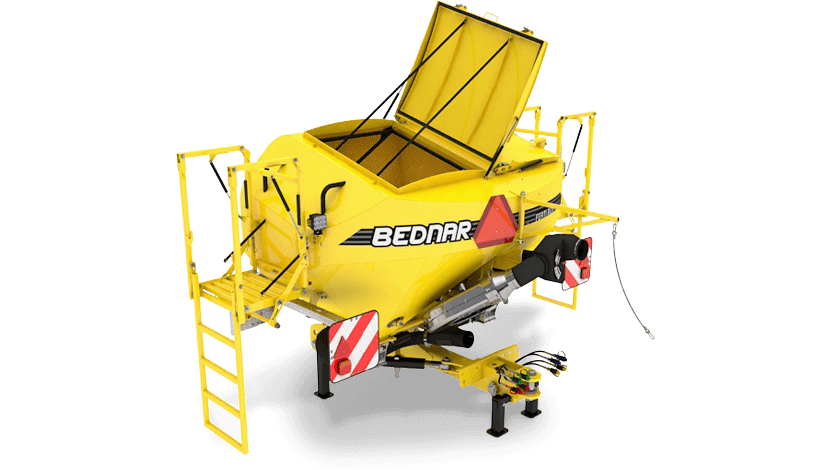

FERTI-BOX FB is a mounted, double-chamber hopper with a total capacity of 3,000 litres, connected to the tractor rear three-point hitch. It is suitable for combination with the TERRALAND TO subsoiler, TERRALAND DO combination subsoiler, or the FENIX FO tine cultivator, to provide fertiliser placement into the soil profile during tillage.

3000 l

A large-capacity, rear-mounted hopper for fertiliser placement with tillage machines.

The FERTI-BOX FB hopper is suitable for fertiliser application in combination with implements for shallow and deep tillage (FENIX FO tine cultivators, TERRALAND TO subsoiler, or TERRALAND DO combination subsoiler).

The FERTI-BOX FB mounted hopper provides a total capacity of 3,000 litres. The hopper is designed as double-chamber for application of two types of fertiliser in one pass. The individual chambers are divided in the ratio of 60:40.

The hopper of the FERTI-BOX FB is pressurised. Thanks to the air-tight closure, overpressure is created in the hopper chamber. This technical solution enables application of large doses with high accuracy, regardless of the size of the seed/fertiliser granules.

The FERTI-BOX FB mounted hopper enables connection to the tractor via ISOBUS technology or control via BEDNAR’s own ISOBUS monitor. A range of control monitors is available with basic or advanced control functions. FERTI-BOX FB is supplied with the BEDNAR EASY CONTROL software, which was developed by BEDNAR engineers.

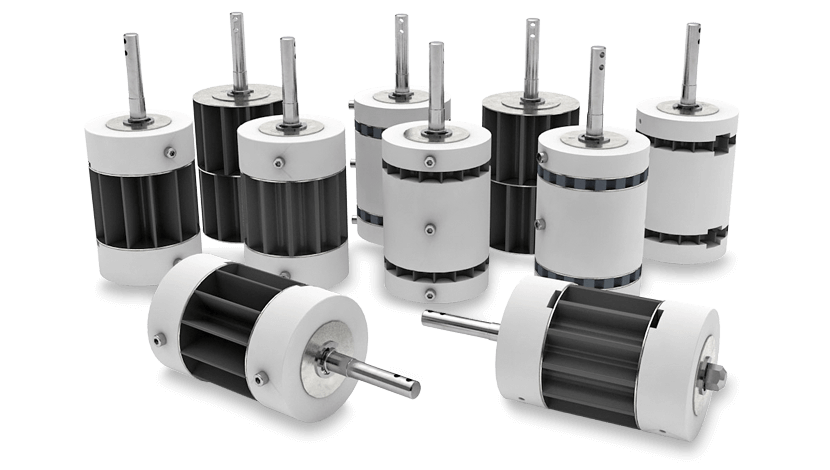

Our portfolio includes various types of metering rollers for the application of different fertiliser and seed sizes. We offer metering rollers from 30 cm³ to 790 cm³.

The mounted FERTI-BOX FB is connected to the rear three-point hitch of the tractor. The hopper has its own frame, to which a trailed machine is attached. The rear hitch can be equipped with a connecting plate or a pin with a diameter of 50 or 70 mm.

The hopper is compact despite its large capacity. The unique shape of the hopper does not obstruct the operator’s view of the attached implement at work hitched behind the hopper.

The BEDNAR developers have designed a mobile phone app that makes it simple to calibrate a mounted hopper right from your phone. The mobile app also includes a guide to help you choose the right metering cassette based on seed/fertiliser type, working speed and seed rate.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main parts of the mounted hopper.

Driven by an electric motor, provides a high accuracy of dosing.

The double-chamber pressurised hopper with a total capacity of 3,000 litres provides accurate dosing of high amounts of fertiliser.

Provide safe and stable parking.

The independent hitch frame enables connection with various trailed implements.

“We currently have two TERRALAND subsoilers by BEDNAR, one with a working width of 6 metres – TO 6000, and one with a working width of 3 metres. We also have additional equipment for TERRALAND TO 6000: Presspack and Cutterpack, as well as FERTI-BOX, used for fertiliser placement.”

Ing. Robert Zhorela,

Chief Machinery Mechanic, Donau Farm, Kalná nad Hronom (district of Levice, SK)

PROFILE FERTILISATION

The placement of fertiliser into the soil environment known as profile fertilisation should be carried out together with deep loosening using FENIX tine cultivators, combination ACTROS cultivators or TERRALAND subsoiler. Such precisely placed fertiliser motivates the root system to grow faster and bigger which helps solve current issues with soil moisture. This fertiliser placement system is most often used for establishing deep-rooting crops such as maize, sugar beet or oilseed rape.

| FERTI-BOX FB | FB 3000 | |

|---|---|---|

| Transport width | m | 3 |

| Transport length | m | 1,9 |

| Transport height | m | 1,9 |

| Hopper volume | l | 3 000 |

| Number of metering units | pcs | 2 |

| Filling hole diameter | mm | 900 × 1040 / 620 × 1040 |

| Filling height | m | in relation to the position of the arms |

| Max. total weight* | kg | 1300 |

*according to the machine equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.