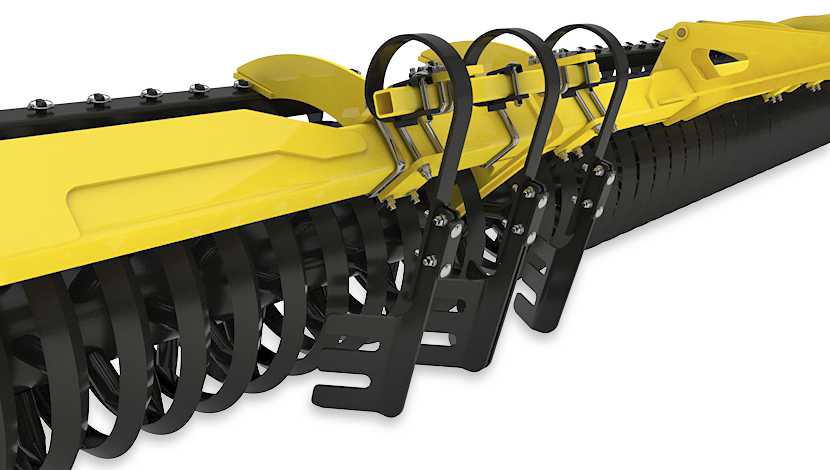

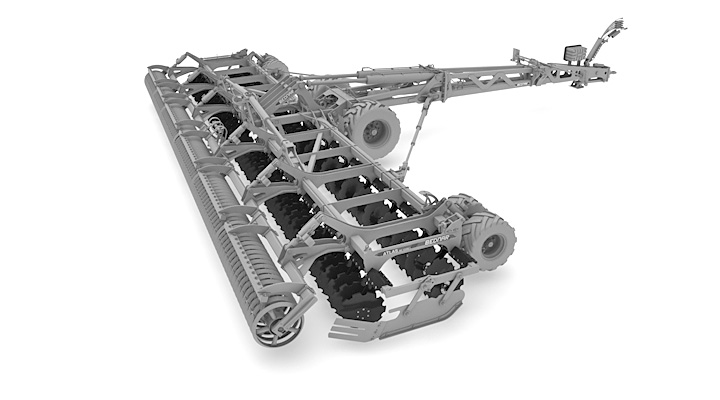

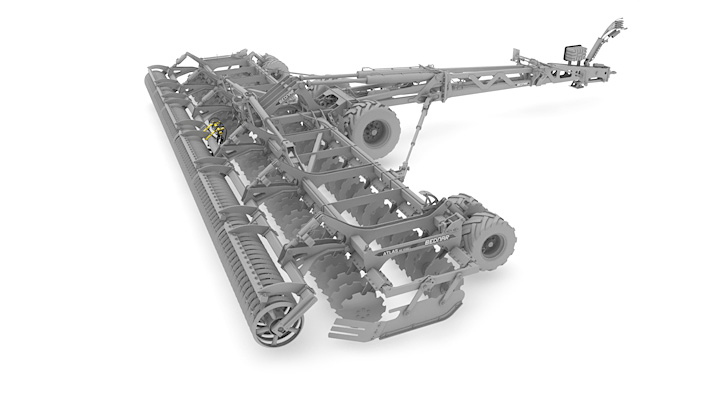

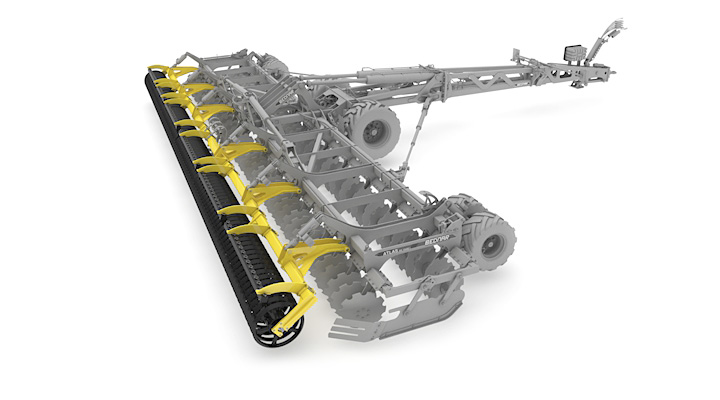

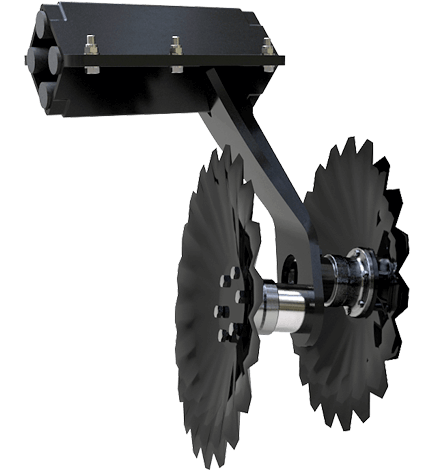

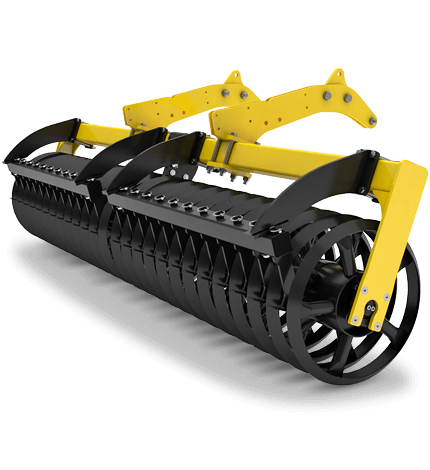

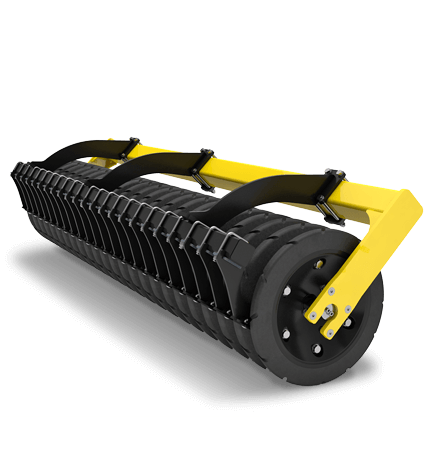

RUBBERPACKER + scrapers

The Rubberpacker is a solid packer made of hard natural rubber, suitable for any conditions. The levelling effect is excellent thanks to the packer weight. Soil adhesion to the packer is almost none thanks to the rubber and scrapers. Packer diameter 590 mm. Weight: 217 kg/m (including scrapers).

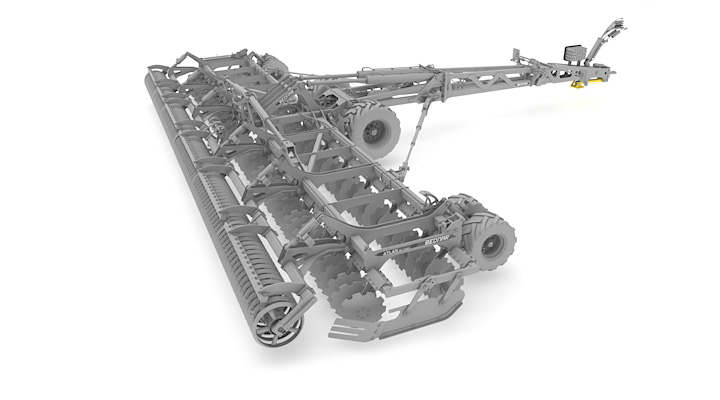

BEDNAR FMT

BEDNAR FMT