Cage roller

The screw-shaped cage roller formed by rods crumbles the clods on the field surface.

Thanks to its low traction requirements, the SWIFTER SN mounted seedbed cultivator is suitable for connection with lower-powered tractors, which are often used by smaller farmers. The working width of these cultivators is 3 to 5 meters, depending on the model selected. The effective combination of working parts ensures intensive leveling, mixing, breaking up clods, and final smoothing of the tilled soil. In a single pass, you can perfectly prepare the seed bed and thus reduce overall costs.

2-12 cm

3-5 m

100-200 hp

Mounted seedbed cultivator suitable for conventional pre-drilling seedbed preparation.

Combining several operations into one means fewer passes through the field and lower costs of seedbed preparation. The front levelling bar perfectly levels any unevenness. The front roller crumbles the clods. The tine section undercuts, aerates and warms up the soil layer. The final clod crumbling is provided by various types of rollers in combination with other equipment behind the rollers.

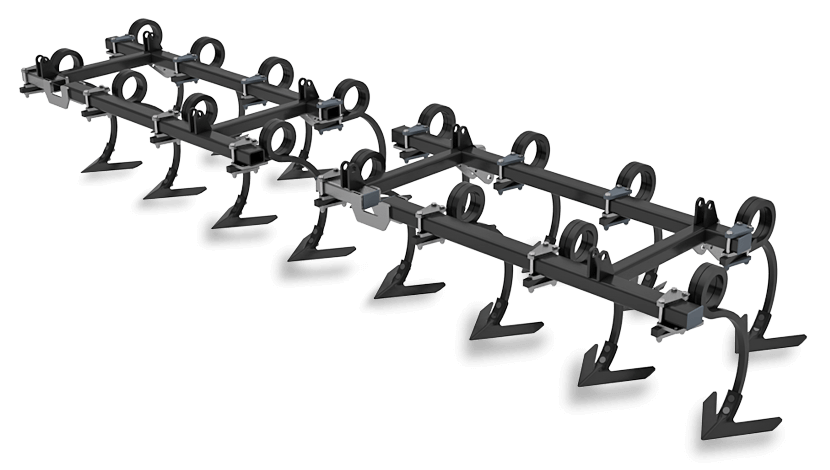

A share section

This working section is suitable for summer and autumn preparation, when the soil needs to be loosened, cut and mixed after the previous harvest. The 270 mm arrow-shaped shares in 2 rows with overlap ensure that the soil profile is cut across the entire working width of the machine, creating a firm bottom. At the same time, the working angle of the shares aggressively processes the soil, creating a loosened top layer. Each share is mounted on a flexible tine, which allows for a “3D effect” (horizontal and vertical movement) that protects the share from damage.

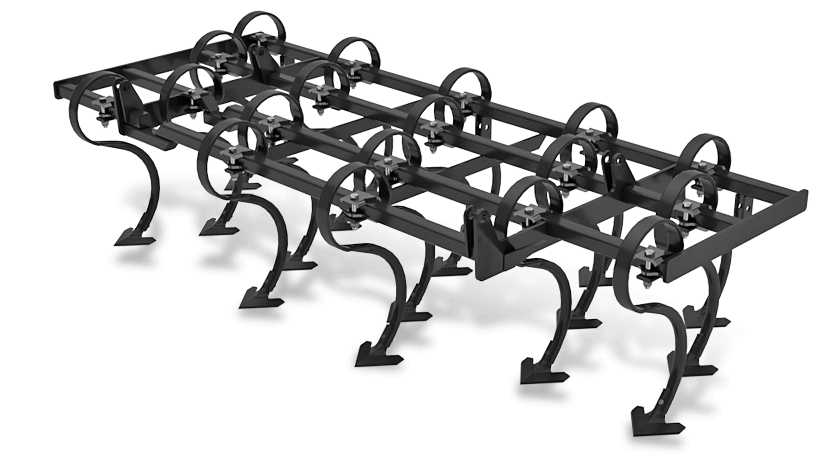

SB section

This section is particularly suitable for spring preparation before of planting sugar beet, when it is necessary to manage spring moisture adequately, but still create a precise seed bed. The angle of the share does not cause vertical mixing of the soil, but thanks to the use of overlapping shares with a working width of 170 mm, the necessary full-area undercutting of the soil is achieved. Another benefit is the reduction in the power requirement of the towing vehicle.

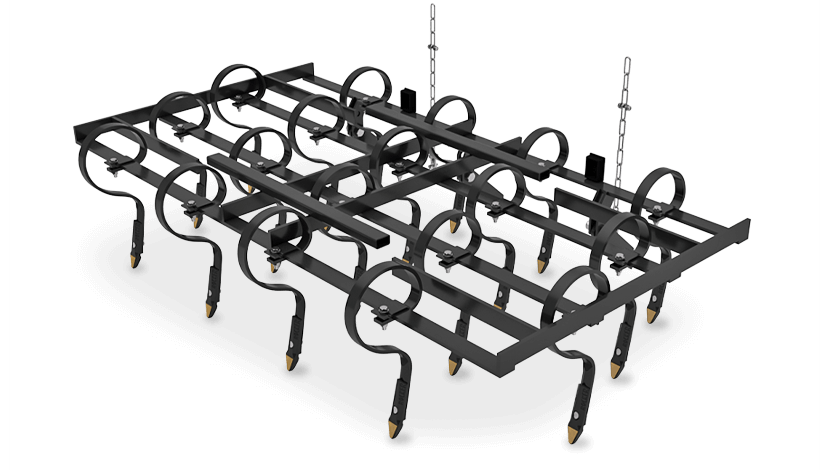

Gamma section

This section is suitable for early spring operations, such as before of seeding barley. Four rows of gamma points at a negative angle aerate and warm the soil without bringing wet particles to the surface, thus preserving winter moisture. This is important for the rapid start of spring growth. The suspension of each tine allows for high-speed operation. Gamma points for this section are also available in a LONG LIFE version.

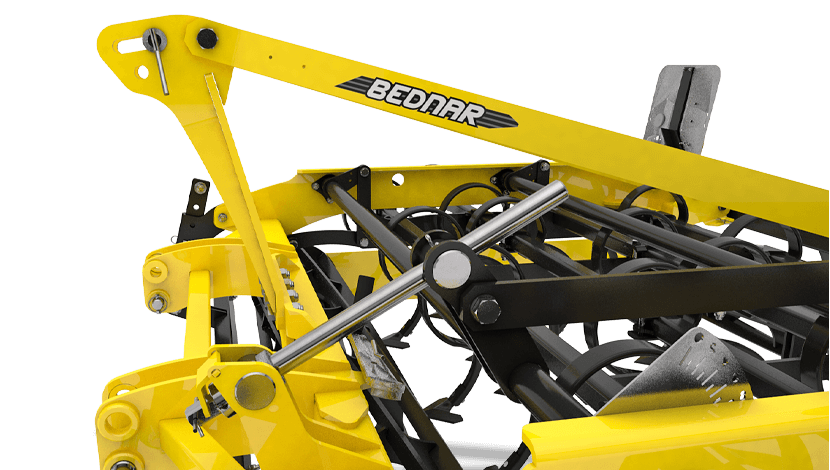

Even the smallest models of the SWIFTER SN mounted seedbed cultivators are easily controllable. You can choose from mechanical adjustment of the working depth, or comfortable hydraulic adjustment.

The working width of the machine is a limiting factor for transportation on roads in the European Union. Therefore, the SWIFTER SN 4000 and 5000 are manufactured in the folding version to ensure safe transport. The centre of gravity of the cultivator is moved as close to the tractor hitch as possible, so the set is stable even at high transport speed.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise overview of the tine section sections of the mounted seedbed cultivator.

Simple hitching to the tractor’s three-point linkage, category II or III.

The mechanically controlled front levelling bar is used for levelling unevenness and breaking the rough furrow.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 rows of shares/ 4 rows of gamma points / 2 rows of SB shares) as needed for seedbed preparation for the crop.

The slatted roller contributes to perfect crumbling of clods created by the share or gamma point section.

The levelling bar creates the final fine soil structure.

Simple hitching to the tractor’s three-point linkage, category II or III.

The mechanically controlled front levelling bar is used for levelling unevenness and breaking the rough furrow.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 rows of shares/ 4 rows of gamma points / 2 rows of SB shares) as needed for seedbed preparation for the crop.

The folding version of the machine is additionally equipped with hydraulic cylinders.

The crosskill roller contributes to perfect crumbling of clods created by the share or gamma-point section.

The finish roller creates the final fine soil structure.

“In order to influence the yield of crops during the initial tillage, it is necessary to use high-quality machines that enable us to do so. That is why I decided to purchase the SWIFTER SN seedbed cultivator, so that I could prepare a high-quality seed bed in a single pass. Yes, some may argue that simple, inexpensive harrows are sufficient for those 45 hectares, but every good farmer knows that in order to ensure good seed germination, it is necessary to prepare a high-quality seed bed. I am also aware of this, which is why I chose the BEDNAR cultivator.”

Karel Řehoř,

Private farmer, Farma na Rychtě, Gruna (district of Svitavy, CZ)

We know requirements for specification and intended use differ. That’s why you can configure the SWIFTER SN seedbed cultivator exactly to your needs.