OMEGA OO_L

9' 10"-29' 6" ft

120-500 hp

80-112 bu

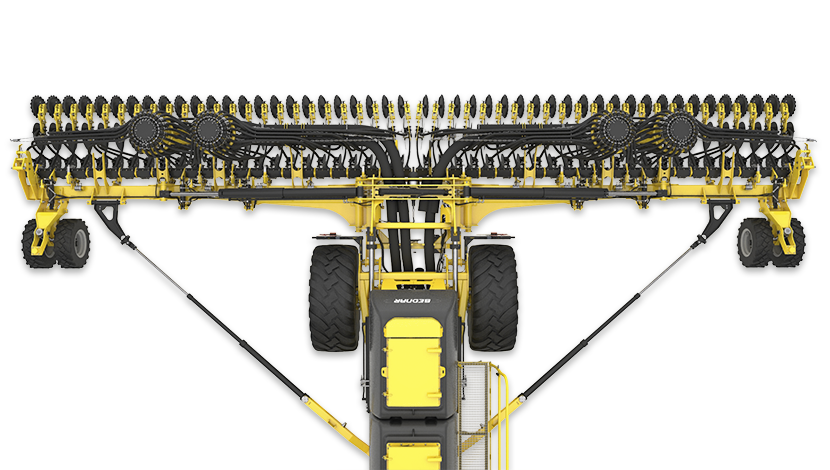

BEDNAR DIRECTO NE is a large no-till air drill with a robust design for drilling crops directly into stubble, cover crops, cultivated or uncultivated soil. The unique single disc opener is able to establish crops even in the most difficult conditions of large amounts of trash or very dry and difficult to work soils.

12 ft

250-350 hp

170- bu

An air drill for no-till and variable establishment of several crops in one pass, including the option of fertilizer placement.

The no-till drilling technology completely differs from the traditional crop establishment methods. Direct drilling does not guarantee increased yields, but it can help you fight soil erosion and deterioration. The considerable reduction in the number of passes reduces soil hardening and avoids disrupting the soil capillary action. The soil cover of the field guarantees minimum moisture evaporation. The root system helps recover the soil structure.

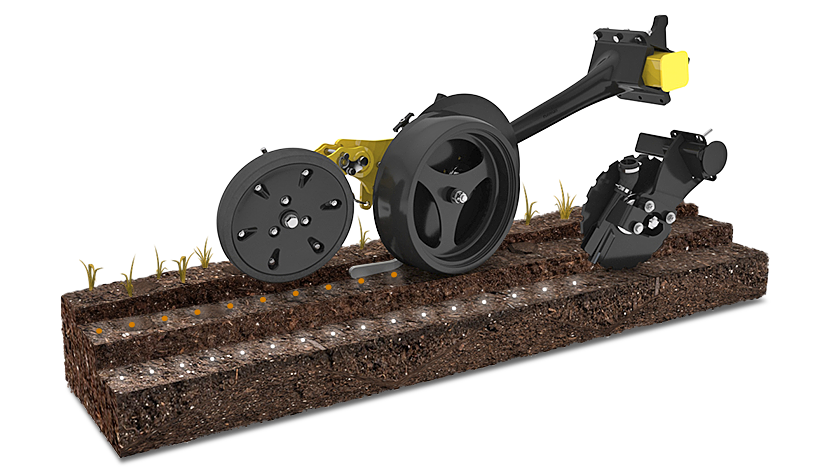

The DIRECT STAR single disc drill opener has been developed over several years to be able to work at 100 % in almost all seeding conditions directly in stubble, cover crops as well as in cultivated soil. Row spacing 10″. The high pressure of 661 lb on the drill opener guarantees correct seed placement even in heavy soils. The minimum seeding depth is 0.3″.

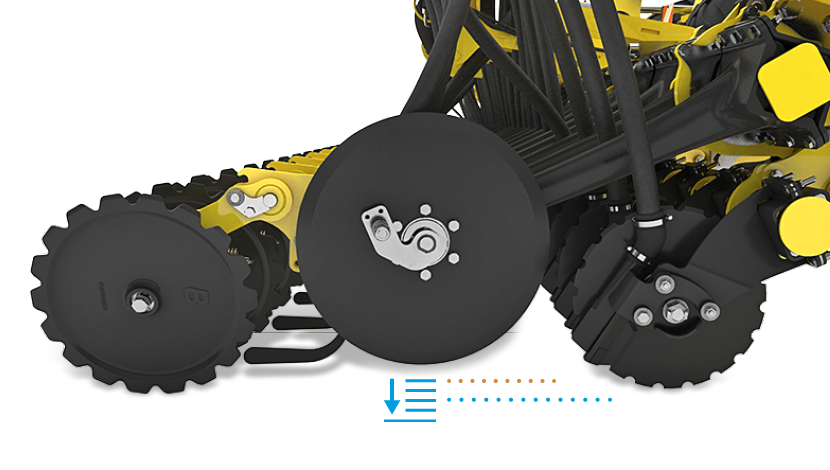

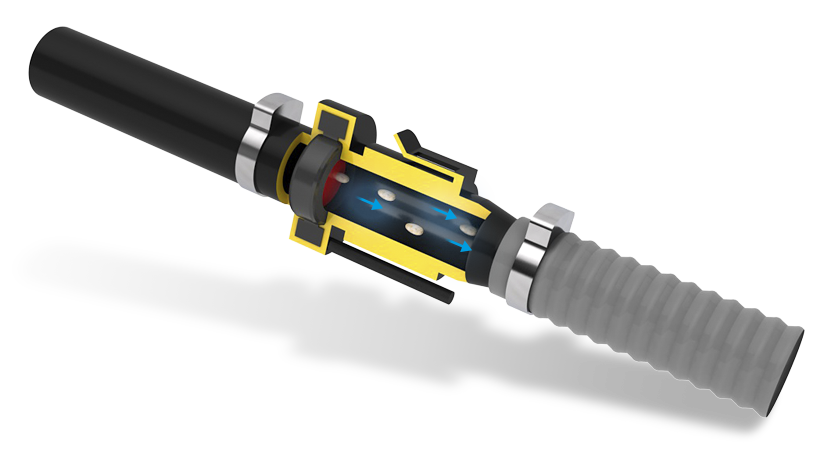

For the DIRECTO NO air drill, we have designed a unique fertilizer opener that places the fertilizer “under the seed” and slightly to the side. The fertilizer application depth can be adjusted from 1.4″ to 4″. The fertilizer openers are mounted on a beam. The fertilizer placement depth of the fertilizer openers is set centrally – there is no need to adjust each opener individually.

The fertilizer oprener applies the fertilizer deeper and slightly to the side. This fertilizer deposited by zone ensures plant nutrition in the later stages of growth and supports targeted root development in the lower layers of the topsoil, thus eliminating stress factors, especially a lack of water. Zonal application improves the development of crops especially in autumn and helps the plants to overwinter better.

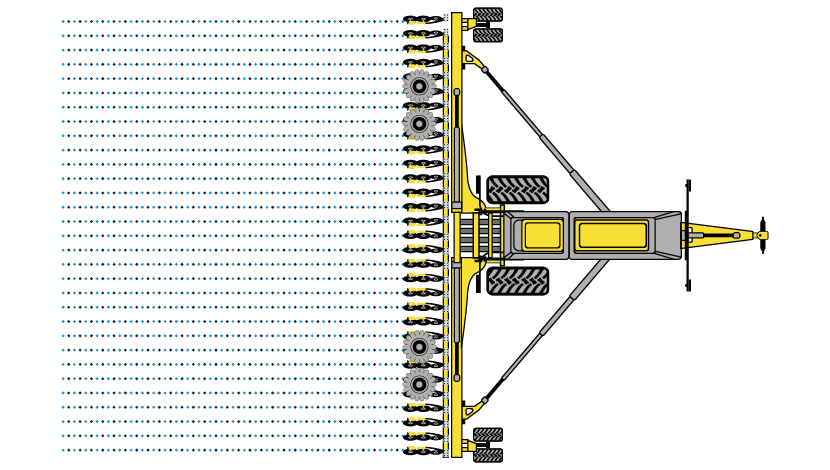

1. The seed is placed in the row together with the fertilizer; the mixing of the seed with the fertilizer takes place in the pipe.

2. Seeding of two types of seeds; seed mixing takes place in the pipeline.

3. Seeding one type of seed (both tanks are filled with one type of seed).

*with the option of switching off 1/4 of the machine’s working width in the case of a machine configuration without fertilizer openers.

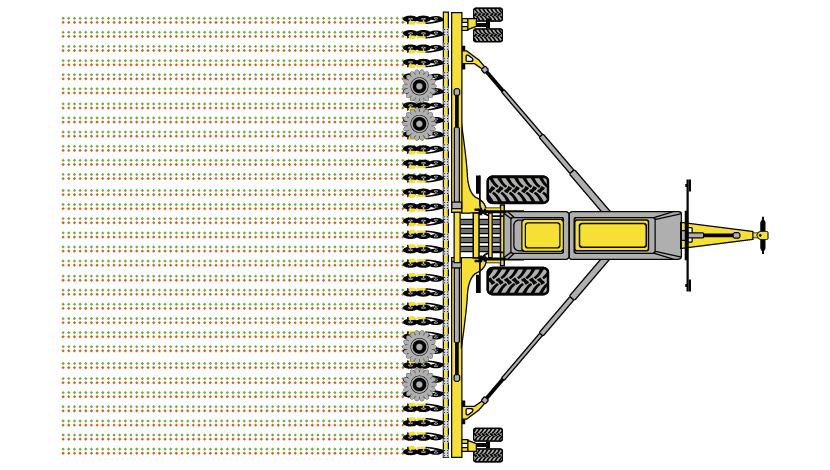

1. The seed is placed in the row using a drill opener, and the fertilizer is placed under the seed and slightly to the side using a fertilizer opener.

2. Seed A is placed in the row using a drill opener, seed B is placed at a greater depth below the seed and slightly to the side using a fertilizer opener.

*with the option of switching off 1/2 of the machine’s working width in the case of a machine configuration with fertilizer opener.

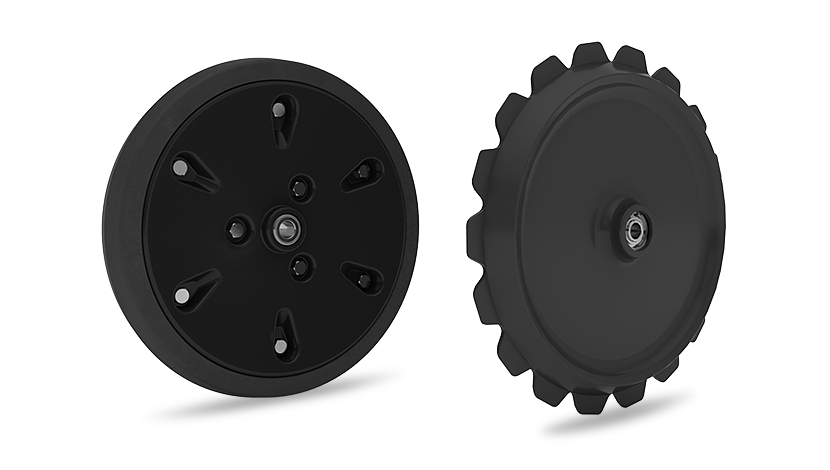

The DIRECTO NE air drill can be equipped with these types of packer wheels – smooth rubber wheel (farmflex), smooth cast iron wheel, toothed cast iron wheel, toothed rubberized wheel. The robust frame of the packer wheel keeps the direction straight. The packer wheel pressure can be adjusted mechanically to close the seed row back, and the angular position of the wheel can be changed (multiple positions – angles). The rear wheel pressure is adjusted on the scale of each drill opener. The pressure is created by a tensioned spring. The spring does not release from the holder.

The BEDNAR uses a pressurized tank solution for all its seed drills. Overpressure is created in the hopper thanks to the airtight closure. This technical design allows the dosing of large seeding amounts with high precision independent of the seed/fertilizer granule size. DIRECTO NE is equipped with a two pressurized tanks with a total capacity of 170 bu.

The fast and comfortable filling of the DIRECTO NE air drill tanks has an easily accessible and wide platform with railing and steps. To fill the hopper, the steel lid swings out 90°. The tank filling level is indicated by two sensors. One is installed higher and its angle is adjustable, the other one is installed in the lower third of the tank.

DIRECTO NE is equipped with four distribution towers for even distribution of seed / fertilizer to the individual drill openers and for the ability to apply high doses of fertilizer and seeds. That ensures the same distance to all drill openers from the distribution tower. This solution also offers a sectional control by every 9′ 10″ of the working width.

The air drill can be equipped with blockage sensors on request. The device ensures that if a drill opener gets clogged, the information is displayed on the screen. That guarantees maximum seeding precision.

Ease of use is a priority for today’s operators. DIRECTO NE is equipped with the new BEDNAR EASY CONTROL software, which guarantees easy and clear operation. The software offers clear, easy and intuitive control of the air drill. If the air drill is equipped with a third hopper, this hopper control is fully integrated into one system (no additional monitor required).

BEDNAR developers designed an application for mobile phones that provides easy and simple calibration of the air drill from your mobile phone. The mobile application includes a guide that helps with the right selection of the seeding roller based on the type of seeds/fertilizer, working speed and seeding amount.

The DIRECTO NE air drill is equipped with large flotation tires measuring 650/65 R30.5 FL. The large tires pressure on soil and eliminate tracks when establishing crops on land with high moisture. The air drill does not exceed a transport width of 9′ 10″.

Even though the DIRECTO NE air drill has a working width of 39′ 4″, its transport on roads is easy and safe. The side frames of the air drill fold forward and the transport length is only 25′ 7″. The wide arrangement of the transport wheels provides a good stability, even at higher speed. The compact dimensions also contribute to easy and fast turning at headland.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerA concise summary of the main working parts of the air drill for direct drilling.

DIRECTO NE is equipped with a hydraulic parking jack for easy “parking” of the air drill.

The pressurized tank can contain large volumes of seed and improves the precision of seeding. The tank is divided in the ratio of 60:40. Total volume is 170 bu.

The gauge wheels with mechanical setting stabilise the air drill. The air drill works in the plane and the set working depth is maintained.

The 4 distribution towers ensure even distribution of seed/fertilizer to individual coulters. The towers allow section control for every 9′ 10″ of width.

The fertilizer opener places the fertilizer “under the seed” and slightly to the side. The working depth of the fertilizer opener is adjusted centrally – there is no need to adjust each opener individually.

The patented drill openers with a high down pressure of 661 lb/opener guarantee quality and even placement of seeds in the soil, even in difficult conditions.

Large flotation tires reduce ground pressure and do not create ruts. Tire size 650/65 R30.5 FL.

NO-TILL DRILLING AS A CURRENT TREND

No-till drilling into soil that has not been cultivated beforehand is a current trend in establishing both main crop and cover crop. Direct seeding is a response to the ongoing increase in drought and water scarcity. The advantage of direct seeding lies in the elimination of soil moisture evaporation, reducing the risk of erosion, soil overheating, and weed growth. It increases the organic matter volume in the soil and significantly saves time and costs required for crop seeding.

| DIRECTO NE | NE 40' | |

|---|---|---|

| Working width | ft | 39' 4" |

| Transport width | ft | 9' 10" |

| Transport length | ft | 25' 7" |

| Transport height | ft | 13' 1" |

| Row spacing | in | 10" |

| Number of drill openers | pcs | 48 |

| Drill opener down pressure | lb | 661 |

| Fertilization disc spacing | in | 10" |

| Number of fertilization coulters | pcs | 48 |

| Drill openers – diameter | in | 17.7" |

| Packer wheels – diameter | in | 14.9" |

| Guiding wheels – diameter | in | 15.7" |

| Tank capacity | l | 170 |

| First tank / second tank ratio | 60:40 | |

| Filling height | ft | 9' 10" |

| Frame type | folding | |

| Horsepower requirement* | hp | 350 |

| Hitch type | lug 51, 55, 62, 71, 73 | |

| Tire size of gauge wheels | 10,0/75-15,3 14PR | |

| Tire size | 650/65-30,5 FL | |

| Max. total weight** | lb | 28,660 |

*not included in basic equipment

**depends on implement equipment