CONFIGURE YOUR OWN

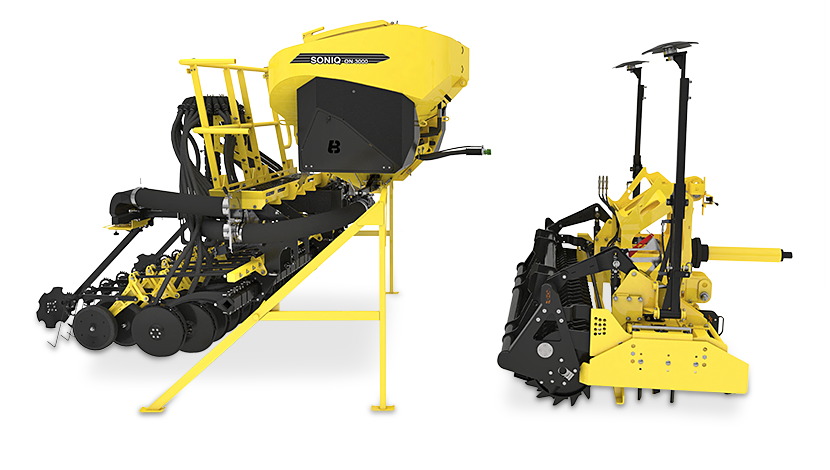

SONIQ ON Seeding Combination

You are one step closer to your new machine.

You can try all the optional equipment in our configurator,

or read more about it in the brochure.

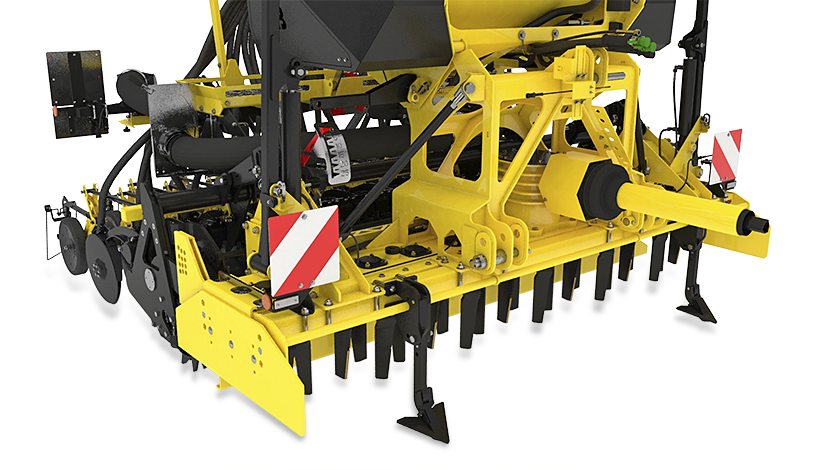

SONIQ ON is a mounted seeding combination with a hopper located above the KATOR power harrows. The KATOR power harrows can be used independently without a hopper and seed bar just for soil preparation. Effective seedbed preparation of the seedbed with power harrows and rear consolidation with a roller. This, together with precise placement of the seed at the required depth, thanks to the PSP2 seed coulters mounted on the parallelogram, guarantees you a perfect result, i.e. strong, healthy and consistent crop shortly after seeding.

3 m

120-180 hp

1000-1600 l

Mounted seeding combination for establishing crops in partially tilled soil or after plowing.

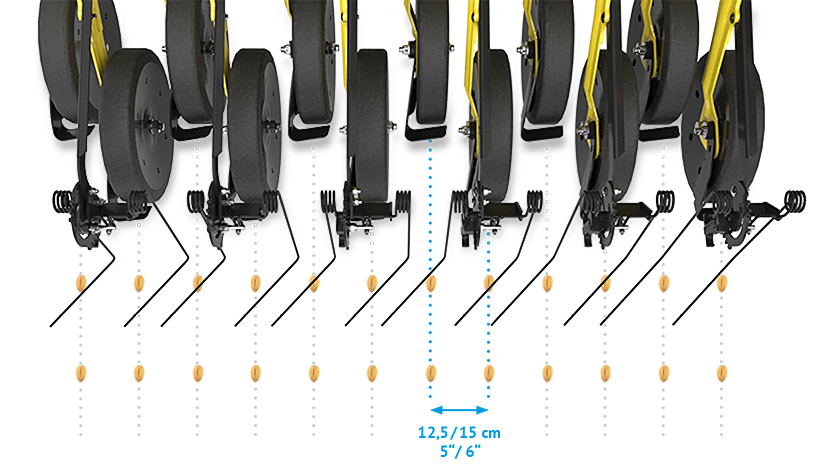

SONIQ ON is designed for farmers using standard tillage technology – plowing. The high number of rotors per meter of working width, combined with high circumferential speed, guarantees high-quality seedbed preparation. The seed has ideal contact with the soil and moisture for rapid development. For this purpose, we have specially developed a seeding unit with a row spacing of 12.5 cm.

The seeding combination is also suitable for establishing crops in a minimum tillage system – for example, deep tillage using rippers or tine cultivators. Power harrows ensure optimal seedbed preparation by breaking up clods, cutting roots and crop residues. The seeding combination with a row spacing of 15 cm is ideal for conditions with a large amount of crop residues on the soil surface.

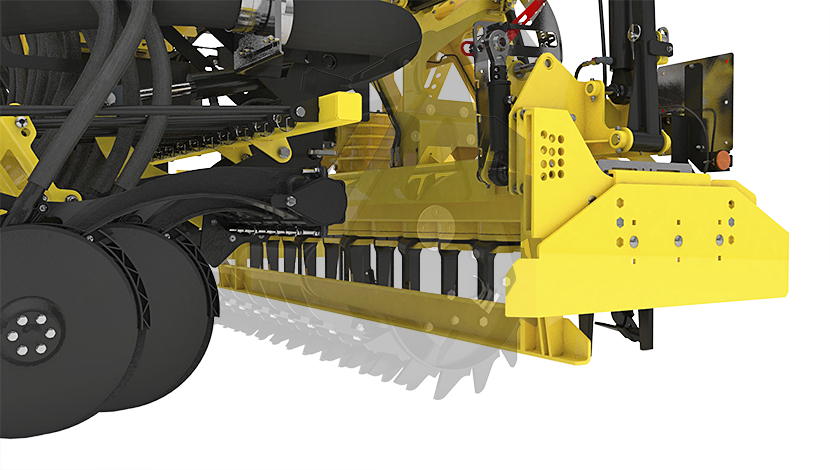

For maximum use of the power harrows, the seed bar can be easily removed. Removing the seed bar is quick, easy, and does not require any special tools. KATOR KN power harrows can therefore be used separately, for example, to prepare the soil before planting potatoes or to prepare the soil on difficult-to-work soils.

If you need to prepare the land for seeding, you do not have to disconnect the bar completely. The advanced system of the SONIQ seeding combination allows the bar to be raised by 7 cm, which allows soil preparation to be carried out without seeding.

The SONIQ ON pneumatic seeding combination is quickly and easily connected to tractor via a 3-point hitch, cat. III.

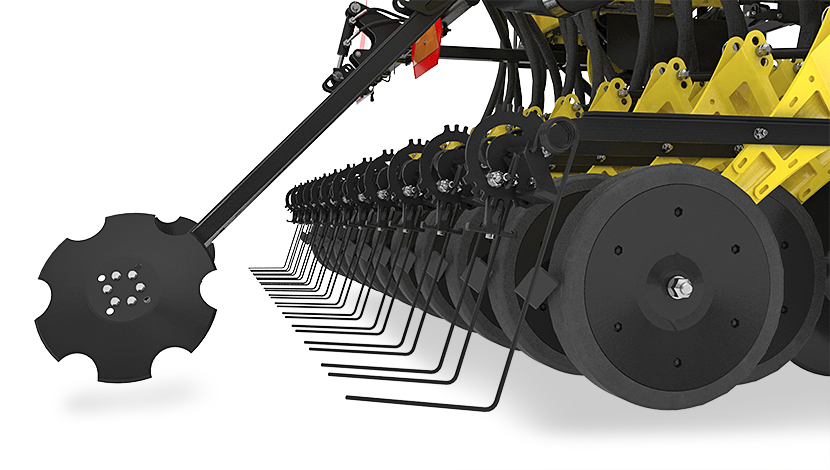

On request, the seeding combination can be equipped with track eradicators for loosening compacted soil in the line of the tractor wheels. The track eradicators are protected with a shear bolt.

KATOR power harrows are the standard preparation implement for SONIQ ON pneumatic seeding combinations. Power harrows create an evenly processed seedbed with a solid substrate for placing seeds or seedlings.

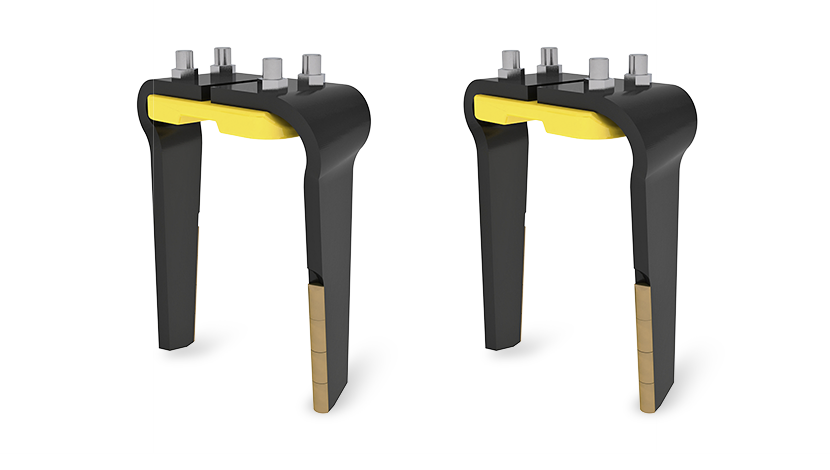

On request, individual models of power harrows can be equipped with a quick blade change system (QUICK CHANGE SYSTEM). This system is a quick and easy way to change blades. You just need to pull out the cotter pin, remove the pin and change the blade. This time-saving system designed to be used without the need for special tools.

For stony soils or extremely heavy soils, we recommend choosing LONG LIFE blades with carbide tips for greater durability.

The levelling bar is positioned very close to the rotors. Large clods of soil are constantly directed back to the rotors to be crushed. The levelling bar is controlled mechanically as standard.

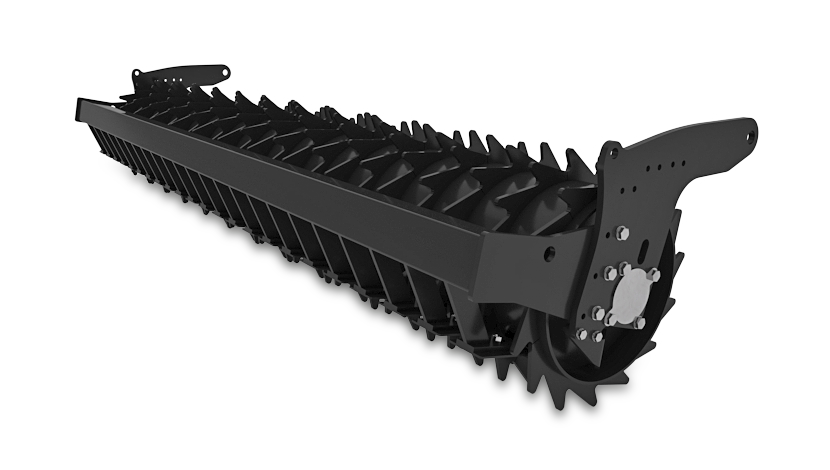

Packer with excellent crumbling effect, suitable for heavy soils. Packer includes scrapers. Packer diameter 550 mm, weight 110 kg/m.

Trapeze packer for precise and fine soil crumbling, ideal packer for light to medium-heavy soils. The packer includes scrapers. Packer diameter 500 mm, weight 125 kg/m.

The power harrow can be easily and quickly detached from the hopper and the seed bar. The hopper and the seed bar have their own parking jack. The power harrow can be used separately for soil cultivation without seeding.

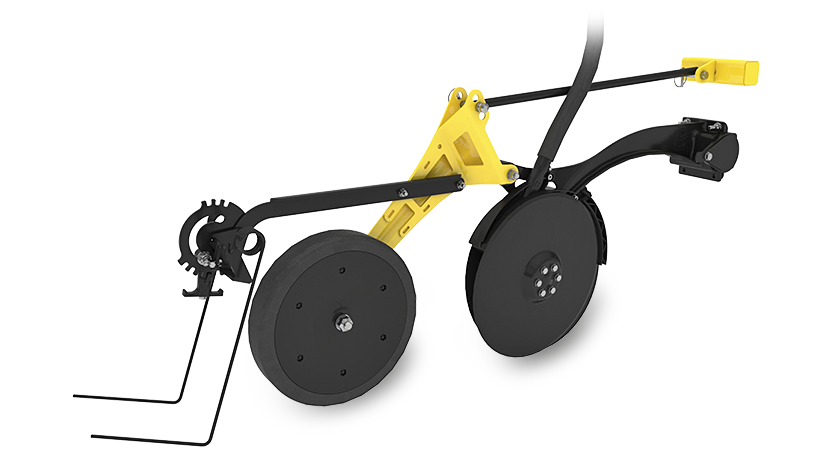

BEDNAR has developed a two-disc seed coulter for heavily loosened soil, exactly the kind that is created after soil cultivation with implements such as power harrows. The PSP2 coulter is based on the proven PSP coulter, which BEDNAR has been using very successfully on OMEGA, EFECTA and MATADOR seed drills for years. The PSP2 coulter is lighter than the PSP coulter with less pressure on the coulter, which is 60 kg for the PSP2 coulter.

The SONIQ ON seeding combination is equipped with seeding coulters with a row spacing of 12.5 cm as standard. This seeding coulter spacing is suitable for systems with a high proportion of cereals in the crop rotation. A row spacing of 15 cm is suitable for establishing crops on heavy soils or in minimum tillage systems.

The tine harrow with fine adjustment and curved tines ensures perfect seed coverage regardless of the amount of plant residues or whether the soil is light or heavy.

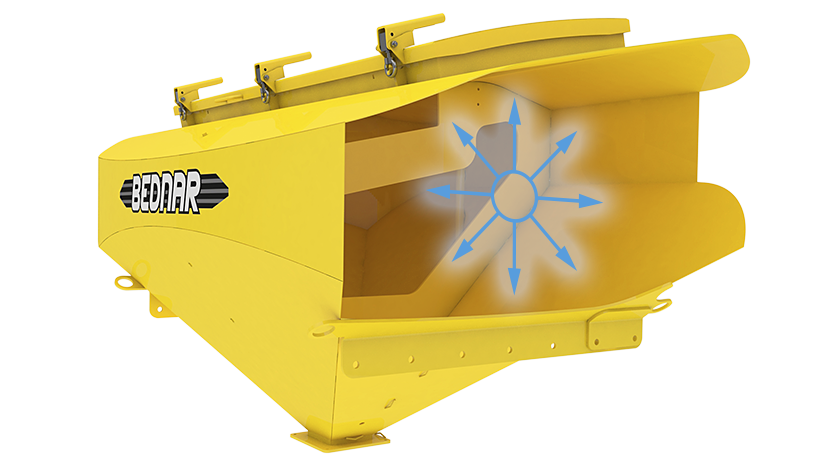

The SONIQ ON has a single-chamber hopper with a capacity of 1000 l or 1600 l. The hopper can be conveniently accessed from the left side of the machine via steps and a platform. The hopper is extended forward which gives optimal center of gravity positioning close to the tractor. Thanks to the contour of the hopper, the seed is fed reliably to the metering unit.

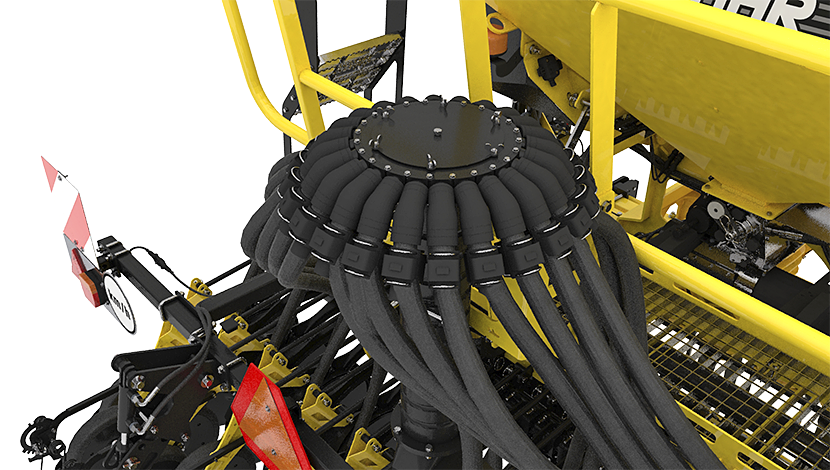

The standard equipment of the SONIQ seeding combination is one distribution head. For maximum precision in seeding and saving on seed costs, the seeding combination can be equipped with two distribution heads. In this case, the seed drill combination offers the possibility of switching off half of the working width of the machine.

Calibration is carried out in the rear part of the seeding combination (behind the seed coulters), where the distribution from the seeding system is brought. A very comfortable and easily accessible place for the operator. In the rear part, it is also possible to conveniently empty unsown seed from the hopper back into the big bags.

Easy operation is a priority for today’s operators. The SONIQ ON seeding combination is equipped with the new BEDNAR EASY CONTROL control software, which guarantees easy and clear operation. The software offers clear, easy, and intuitive control of the seed drill.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerEasily accessible three-point hitch cat. III for connection of a seeding combination to the rear three-point tractor hitch.

Proven KATOR KN power harrow with a high number of rotors per meter of working width for quality crumbling and tillage.

The robust gearbox for perfect power transfer ensures quality and reliable work of each individual rotor within the rotary harrow.

The rear packer helps in the final crumbling of clods and creates the seedbed structure.

The SONIQ ON seeding combination is equipped with a single-chamber, pressurised hopper with a capacity of 1000 l or 1600 l. The SONIQ ON model has one metering unit

The seed bar is made up of the proven solution of PSP2 double-disc seed coulters, which are mounted via parallel linkage. Optional row spacing of 12.5 cm and 15 cm.

SONIQ ON comes with one distribution head as standard. If it is necessary to switch off half of the working width, the SONIQ ON seeding combination can be equipped with two distribution heads.

These are used to mark a guide line for smoothly connecting individual passes if the tractor is not equipped with GPS navigation.

You are one step closer to your new machine.

You can try all the optional equipment in our configurator,

or read more about it in the brochure.

CROP ESTABLISHMENT

Each crop requires specific conditions for its establishment, based on the selected soil cultivation technology and weather conditions. Generally, the crop should be established by the specified agronomic deadline to meet all the preconditions for achieving the required yield.

| SONIQ | ON 3000 | |

|---|---|---|

| Working width | m | 3 |

| Transport width | m | 3 |

| Transport length | m | 3,6 |

| Transport height | m | 2,4 |

| Drill coulter spacing | cm | 12,5 / 15 |

| Number of drill coulters | pcs | 24 / 20 |

| Drill coulter down pressure | kg | 60 |

| Number of rotors | pcs | 12 |

| PTO shaft RPM | RPM | 750 / 1000 |

| Rotor RPM | RPM | 346 / 462 |

| Distance between rotors | cm | 24,5 |

| Blades size | mm | 330x15 |

| Max. working depth* | cm | 25 |

| Hopper volume | l | 1000 (1600) |

| Filling height | m | 3 |

| Frame type | rigid | |

| Power demand* | HP | 120 - 180 |

| Max. total weight** | kg | 3420 |

*depends on soil conditions ** depends on the equipment