April

2025

ROTO-MASTER RMN Rotary Hoe – Not…

The ROTO-MASTER RMN rotary hoe is a versatile machine suitable for both organic and conventional farming. It can be used across a wide…

The ROTO-MASTER RMN is a rotary hoe designed for the complete mechanical weed control and breaking up the soil crust. The machine’s robust design allows it to reach working speeds of up to 30 km/h. The ROTO-MASTER RMN is a highly versatile machine that can be used with cereal, sugar beet, sunflower, maize and soybean crops.

4 cm

6-12,4 m

90-200 hp

Rotary hoe for use in different soil conditions and different stages of plant growth.

The ROTO-MASTER RMN rotary hoe is a machine that can be used in both organic and conventional farming. It can be used for a wide range of crops. At a time when intense weather events are increasingly frequent, the rotary hoe is the ideal tool. The ROTO-MASTER can cut the soil crust after adverse weather or stop capillary rise, thus conserving soil moisture in the event of drought. With a view towards reducing the use of plant protection products, the rotary hoe can also be used for mechanical weed control.

The ROTO-MASTER RMN rotary hoe is a machine that can be used in both organic and conventional farming. It can be used for a wide range of crops, both densely sown and row crops. At a time when intense weather events are increasingly frequent, the rotary hoe is the ideal tool. The ROTO-MASTER can cut the soil crust after adverse weather or stop capillary rise, thus conserving soil moisture in the event of drought. With a view towards reducing the use of plant protection products, the rotary hoe can also be used for mechanical weed control.

The ROTO-MASTER RMN rotary hoe is a machine that can be used in both organic and conventional farming. It can be used for a wide range of crops, both densely sown and row crops. At a time when intense weather events are increasingly frequent, the rotary hoe is the ideal tool. The ROTO-MASTER can cut the soil crust after adverse weather or stop capillary rise, thus conserving soil moisture in the event of drought. With a view towards reducing the use of plant protection products, the rotary hoe can also be used for mechanical weed control.

The main frame of the machine is designed to withstand maximum load. The great robustness of the frame contributes to a high working speed of up to 30 km/h, which, combined with the large working width, ensures high daily performance. The weight of the frame itself exerts sufficient downforce on the individual rotary star wheels.

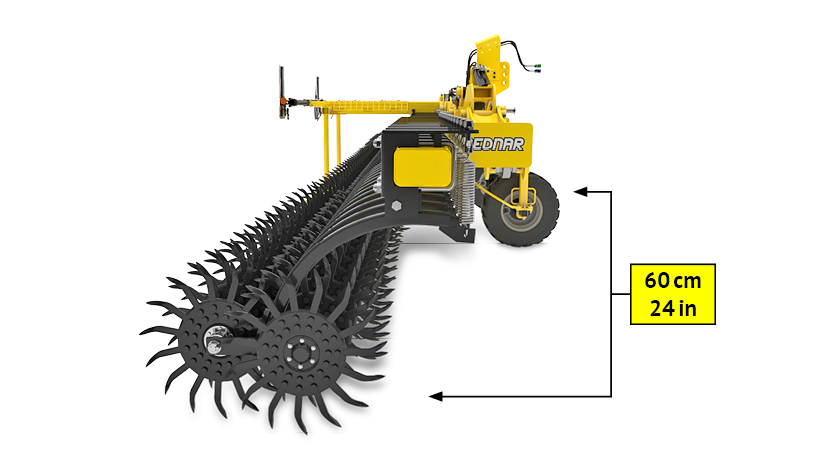

The ROTO-MASTER RMN rotary hoe offers a high frame clearance of 60 cm. The high frame clearance guarantees excellent machine throughput even through mature vegetation, and allows cultivation of the crop even at a later phase of growth.

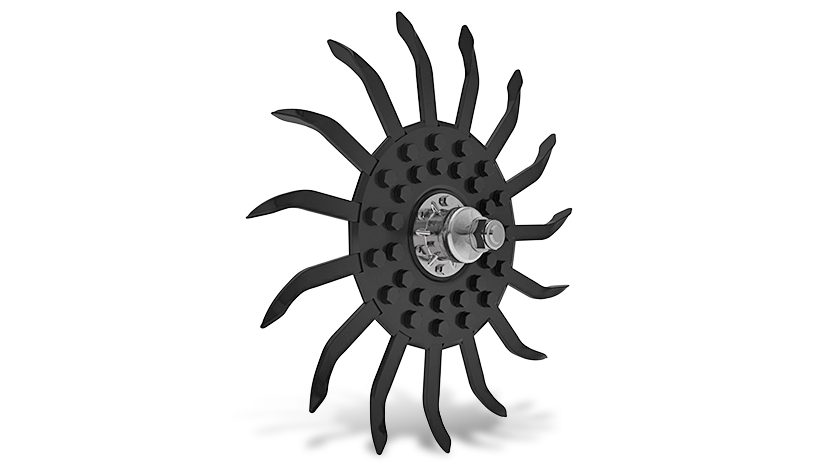

Each arm is attached to the frame by a clamp using spring reset arm protection. The arms are always fitted with two star wheels, which perfectly contours the terrain. The rotary star wheels have an offset arrangement in order to achieve high throughput. Each rotary star wheel (480 mm diameter) is fitted with 16 fingers.

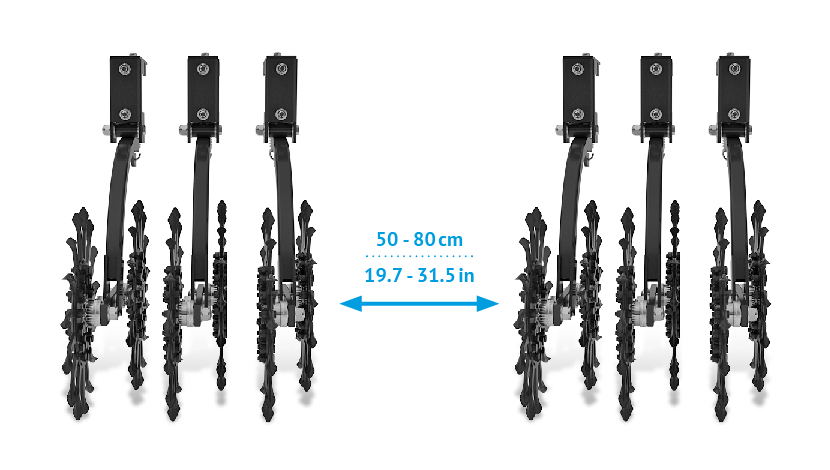

The ROTO-MASTER RMN is a machine designed for full-area cultivation. However, with an easy modification, row cultivation can also be carried out with any row spacing (50/70/75 or 80 cm) to avoid damage of the crop.

The ROTO-MASTER RMN is equipped with support wheels to ensure precise machine operation and prevent crop damage. On wide working width machines, they provide a clear advantage in terms of stability, terrain contouring and keeping of working depth. The height of the support wheels and the wheel track are adjusted mechanically. This means that the machine can be used with all crops regardless of row spacing.

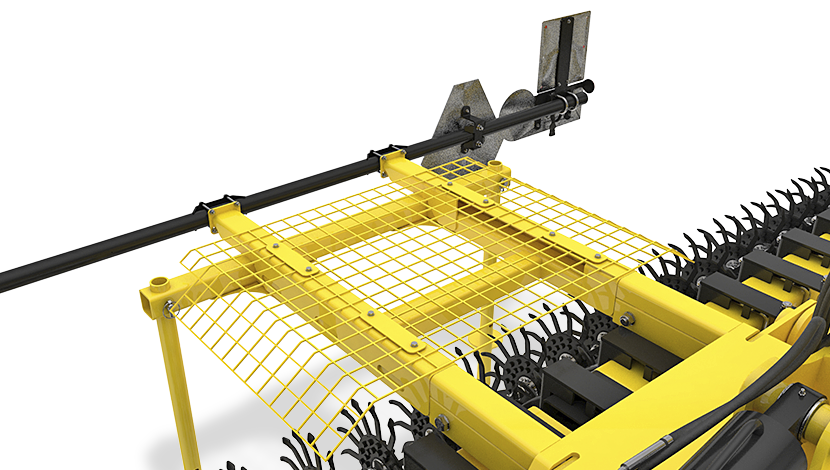

The ROTO-MASTER RMN is equipped with a protective cover in the middle of the machine. The protective cover prevents damage of the tractor, for example by flying stones, and contributes to the safety of the operator during work.

In the case of wear or damage to the fingers on the rotary star wheel, the individual fingers can be easily replaced without having to replace the entire star wheel, which clearly contributes to cost savings. You only need a wrench to unscrew the two bolts that hold the finger.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerThe main working parts of the rotary hoe in a concise and clear design.

The height and track width of the support wheels are adjusted mechanically. The support wheels ensure optimal terrain contouring and precise retention of the set working depth.

The robust support frame contributes to machine stability during work and allows high working speeds of up to 30 km/h.

The individual arms are attached to the frame by a clamp. A spring protects each individual arm against overloading. The arms can be adjusted to the required row spacing.

The rotary star wheels have an offset arrangement for excellent machine throughput. There are two star wheels on each arm.

The middle section has a protective cover that prevents damage to the tractor caused by some hard particles such as stones.

FULL-SCALE MECHANICAL CROP CULTIVATION

Mechanical weeding improves the soil’s physical properties, plant nutrient uptake and crop condition. Full-scale mechanical loosening helps to limit herbicide use on the field. Full-scale loosening also has a soil-conservation effect. The loosened topsoil layer prevents rapid surface water runoff and reduces the risk of water and wind erosion.

| ROTO-MASTER | RMN 6000 | RMN 9000 | RMN 12400 | |

|---|---|---|---|---|

| Working width | m | 6 | 9 | 12,4 |

| Transport width | m | 3 | 3 | 3 |

| Transport length | m | 2,2 | 2,2 | 2,2 |

| Transport height | m | 3,2 | 3,6 | 3,6 |

| Number of rotating stars | pcs | 58 | 86 | 118 |

| Spacing of star wheels/units | cm | 10,5 / 21 | 10,5 / 21 | 10,5 / 21 |

| Max. working depth* | cm | 4 | 4 | 4 |

| Frame clearance | cm | 60 | 60 | 60 |

| Power demand* | hp | 90 - 110 | 110 - 160 | 160 - 200 |

| Frame type | folding | folding | folding | |

| Max. total weight** | kg | 2041 | 3219 | 3701 |

*depending on soil conditions **according to equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.

Do you need help with your selection? Are you interested in a demonstration of the machine? Contact us!