SMOOTH ROLLERS

Smooth rollers are an optional feature of the machine to increase its utilisation throughout the year. Ideal for rolling land after sowing or maintaining permanent pasture.

DURACUT TE cutting rollers ensure shallow processing of the topsoil typical for vertical tillage. This technology limits soil structure disturbance, especially in the horizontal direction. Only the top layer of soil is loosened. The result is more reliable water retention in the soil, reduced erosion, and very good conditions for seed germination. The arrangement of the blades in a V pattern offers high cutting capacity. This process effectively stimulates the emergence of volunteer plants.

7,5-12,5 m

150-360 hp

Cutting rollers designed for cutting and incorporating crop residues with a vertical tillage effect.

The DURACT TE is a highly interesting machine from an agronomic point of view. It offers an economical method for disposing of crop residues and mixing them with the topsoil. This working operation helps to promote the decomposition of crop residues and is a very effective way of combating certain pests such as the European corn borer and slugs.

The DURACT TE is a highly interesting machine from an agronomic point of view. It offers an economical method for disposing of crop residues and mixing them with the topsoil. This working operation helps to promote the decomposition of crop residues and is a very effective way of combating certain pests such as the European corn borer and slugs.

The DURACT TE is a highly interesting machine from an agronomic point of view. It offers an economical method for disposing of crop residues and mixing them with the topsoil. This working operation helps to promote the decomposition of crop residues and is a very effective way of combating certain pests such as the European corn borer and slugs.

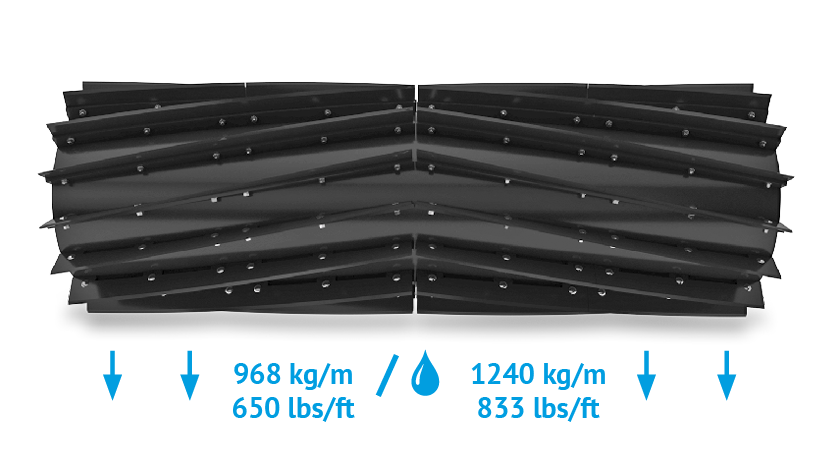

DURACUT TE can be equipped with 940 mm diameter rollers. During operation, the entire weight of the frame and water in the rollers rests on the blades. This solution maximizes the cutting effect of the rollers even on hard crop residues such as corn. In the case of the TE 12400, the machine weight per metre is 968 kg. The cutting rollers can be filled with water to increase the cutting effect, where the weight is then up to 1,240 kg/m.

The DURACUT TE blade arrangement in the patter of ,,V” that allows for aggressive work and ideal results regardless of working conditions. This technical solution guarantees the so-called soil cutter effect (possibility of tilling even several centimetres of soil).

The DURACUT TE cutting roller comes in contact with a large amount of material during work. To guarantee maximum durability and minimum wear, the replaceable ENDURANCE blades are made of high wear-resistant steel. In case of damage or replacement, their design allows for quick and easy replacement.

DURACUT TE has a middle frame and two side folding frames. Each roller is independently suspended to the frame. This technical solution ensures ideal terrain contouring, even when working on uneven ground. In addition, the individual rollers are positioned so that they overlap by only a few centimetres to ensure quality processing over the machine working width.

The DURACUT TE can be equipped upon request with smooth, 914 mm diameter rollers, which can be used during the year for ground levelling (permanent pasture maintenance) or rolling the land after seeding to secure better seed-to-soil contact and reduce soil moisture evaporation. The rollers can be filled with water to increase the weight. Smooth and cutting rollers are easily replacable on the machine.

The DURACUT TE cutting roller uses the proven concept of folding and unfolding the machine into the pattern of an “E” (middle frame and two side folding frames). This concept offers quick and easy folding of the machine from/to the transport position. In addition, the wide 700/40-22,5 tyres ensure great machine stability during transport. The high ground clearance enables safe machine runs, for example along dirt roads.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerThe main parts of a trailed cutting roller in a concise summary.

Ensures easy and safe machine parking.

The robust frame contributes to the machine’s long service life and handles high working speeds.

Cutting rollers with a diameter of 940 mm. Standard or replaceable roller blades.

Each roller is independently suspended to the frame, a technical solution that offers perfect terrain contouring.

The replaceable blades are made of high-strength HARDOX steel can be easily replaced when necessitated by damage or wear.

Ensures easy and safe machine parking.

The robust frame contributes to the machine’s long service life and handles high working speeds.

The 914 mm diameter rollers are designed for rolling land after sowing to ensure better seed-soil contact and reduce soil moisture evaporation.

Each roller is independently suspended to the frame, a technical solution that offers perfect terrain contouring.

CROP RESIDUE MANAGEMENT

Processing crop residues or catch crops before the onset of winter is important for several reasons. Crop residues are a source of organic matter, and for rapid decomposition, their efficient shredding and subsequent incorporation into the soil is essential. The incorporation of crop residues increases the activity of micro-organisms, and the converted organic matter subsequently provides plants with an additional source of nutrients and natural stimulation. A slight disturbance of the topsoil after harvest accelerates the germination of seed admixture, allowing it to be destroyed in time for the next cash crop to be seeded.

| DURACUT TE | TE 7500 | TE 12400 | |

|---|---|---|---|

| Working width | m | 7,5 | 12,5 |

| Transport width | m | 3 | 3 |

| Transport length | m | 5,1 | 8,4 |

| Transport height | m | 3 | 3,6 |

| Number of cylinders | ks | 3 | 5 |

| Cylinder diameter – cutting | mm | 940 | 940 |

| Cylinder diameter – smooth | mm | 914 | 914 |

| Power demand* | HP | 150 - 250 | 250 - 360 |

| Hitch type | towing eye 40, 51, 55, 58, 62, 71, 73 | towing eye 40, 51, 55, 58, 62, 71, 73 | |

| Transport tyre dimensions | 700/40-22,5 | 700/40-22,5 | |

| Max. total weight - without water / with water (standard knives) | kg | 6800 / 8700 | 10900 / 14300 |

| Max. total weight - without water / with water (replaceable knives) | kg | 7400 / 9300 | 12100 / 15500 |

| Max. total weight - without water / with water (smooth rollers) | kg | 6500 / 9130 | 11070 / 15470 |

*depending on machine equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.

Do you need help with your selection? Are you interested in a demonstration of the machine? Contact us!