October

2024

NEW BEDNAR PRODUCTS AND INNOVATIONS FOR…

As usual, BEDNAR is launching new products as the current year draws to a close and the new 2025 business season begins.

The KATARA KN_S mounted seed drill combination is designed for conventional farmers seeking a combination of high yields and farming efficiency by minimizing the number of working operations. KATARA KN_S brings the best of BEDNAR technical solutions. It is a combination of KATOR KN power harrow, recognised for their robustness and higher number of rotors per foot of working width, with a well-proven seed bar.

19' 8" ft

280-430 hp

Mounted seed drill combination for establishing crop stands in partially cultivated soil or after tillage.

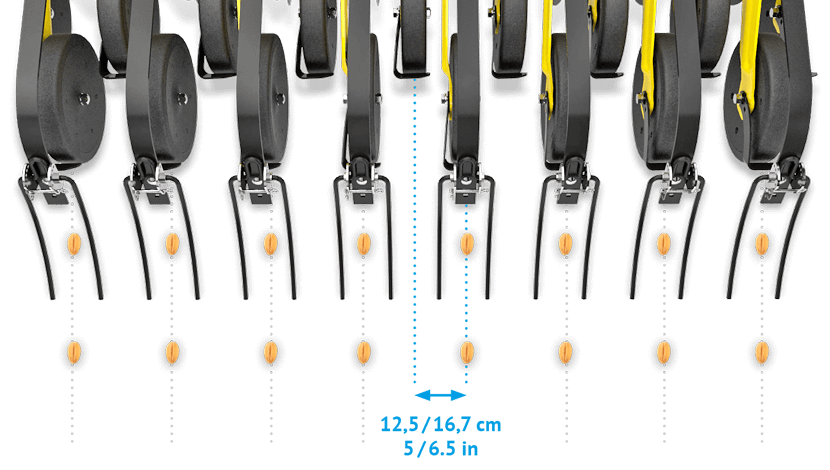

KATARA KN_S is designed for farmers using standard tillage technologies. The high number of rotors per foot of working width in combination with high circumferential speed guarantees quality preparation of the seedbed. The seed has superb contact with the soil and moisture for subsequent development. For this purpose, we have specially developed a seed bar with an row spacing of 5″.

The seed drill combination is also suitable for establishing crops in no-till systems – e.g. deep tillage using a chisel plough or field cultivator. Power harrow ensures the optimum seedbed preparation by crumbling clumps and cutting roots and plant residues. The seed bar with row spacing of 6.5″ is perfect for high plant residue levels on the soil surface.

For maximum use of power harrow, the seed bar can simply be dismounted. Disconnection of the seed bar is fast, easy and requires no special tools. The KATOR KN power harrow can therefore be used separately, for example for preparing seedbed prior to planting potatoes or seedbed preparation for hard-to-work soils.

If you need in between seedings quality preparation of the soil for seeding, you do not have to disconnect the seed bar. The well thought-out KATARA KN_S seed drill combination enables lift up seed bar by 6″ so the actual seedbed preparation can be done without simultaneous seeding.

The KATARA KN_S seed drill combination in the transport position offers one of the smallest transport widths on the market – 8′ 2″. KATARA KN_S fulfills all EU requirements for road travel. The seeding bar is very close to the rear packer. This structural property is key for an optimum centre of gravity, which is very close to the rear tractor hitch.

The heart of the KATARA KN_S seed drill combination is its proven KATOR power harrow, which offers the greatest number of rotors per foot of working width. The spacing of individual rotors is 9.65″. The high number of rotors ensures quality crumbling of soil, even in dry periods or during cultivation of hard-to-work soils. Hydraulic adjustment of the working depth of the power harrow is a part of the basic implement equipment.

The KATARA KN_S seed drill combination is fitted as part of the standard equipment with seed openers with an row distance of 5″. This spacing of seed openers is suitable for systems with a high representation of cereals in the sowing procedure. The row spacing of 6.5″ in is suitable for establishing crop stands on hard soils or in minimum tillage systems.

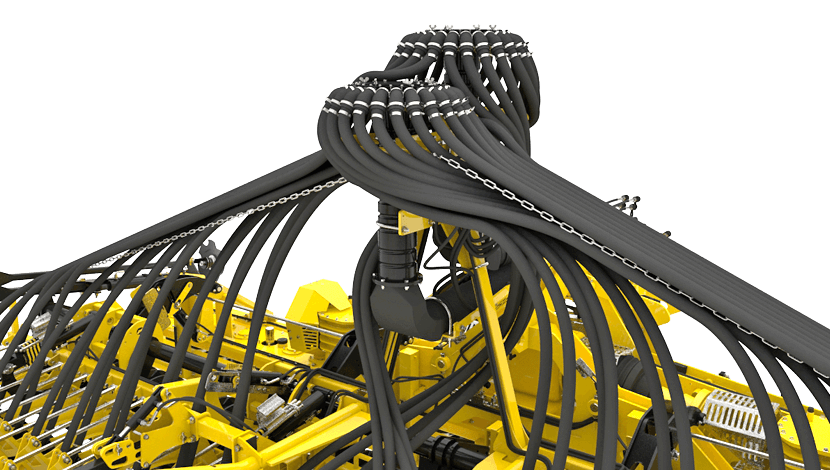

From the first designs, the KATARA KN_S was intended to feature a user-friendly system of seed bar disconnection. The distribution tower is a part of the seed bar frame, so it requires no additional disassembly. Between the distribution tower and power harrow frame is a bracket, attached to which are the distribution pipes, hydraulic hoses and cable harnesses. The seed bar is simply detached using the quick-release stops and safely placed on the parking jack. The entire disassembly process is quick and requires no tools.

As a part of the basic equipment, the KATARA KN_S seed drill combination features one distribution tower. For maximum precision when seeding and saving seed costs, the seed drill combination can be fitted with a pair of distribution towers. In this case, the seed drill combination offers the option of switching off half of the seed bar working width.

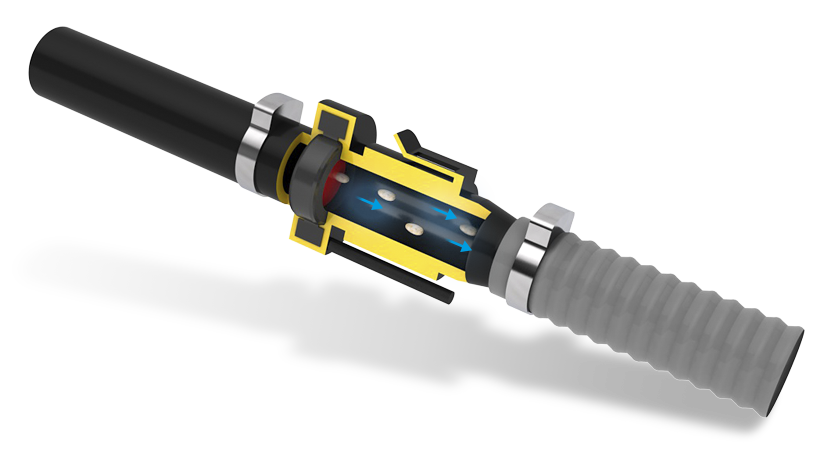

The seed drill combination can be equipped upon request with blockage sensors that provide the operator information through the monitor in case of clogging of the seed hose. This element guarantees maximum seeding accuracy. The operator always has a perfectly clear overview of the fluid flow of individual seed hoses

Connection of the seed drill combination with BEDNAR FERTI-BOX FB_F / FB_F Dual or SEED BOX SB front tanks guarantees maximum compatibility and accuracy during seeding. BEDNAR has long used pressurised tank design ensuring high dosing accuracy regardless of the seed or fertilizer grain size. It features easy seed rate adjustment or the option of variable dosing based on prescription maps.

Ease of use is a priority for today’s operators. The KATARA KN_S seed drill combination is equipped with the new BEDNAR EASY CONTROL software, which guarantees easy and clear operation. The software offers clear, easy and intuitive control of the seed drill.

Do not hesitate to contact us or find the dealer for your area.

Contact us Find a dealerThe main working tools of a mounted seed drill combination concisely and clearly.

Easily accessible three-point hitch for connection of a seed drill combination to the rear three-point tractor hitch.

The robust gearbox for perfect power transmission ensures quality work of individual rotors of the power harrow.

Proven KATOR KN power harrow with a high number of rotors per foot of working width for quality crumbling and tillage.

The rear packer helps in the final crumbling of clumps and creates the seedbed structure.

The pair of distribution towers ensures fluid seed flow to the seed openers. This configuration enables switching off of half the seed bar working width for maximum precision and saving on seed.

The seed bar is formed of a proven solution of twin-disc seed openers mount on parallel linkage for even seed application into the soil in the entire seed bar working width. Optional row spacing of 5″ or 6.5″.

It is useful for marking guide lines for smooth continuity of individual working widths in case the tractor is not equipped with GPS navigation.

The drill openers are attached to the seed bar frame with a parallel linkage. The system perfectly maintains the set working depth along the entire width of the seed bar.

You are one step closer to your new implement.

You can try all the implements in our configurator,

or read about it in the brochure.

| KATARA KN_S | KN 20' S | |

|---|---|---|

| Working width | ft | 19' 8" |

| Transport width | ft | 8' 2" |

| Transport length | ft | 5' 7" |

| Transport height | ft | 11' 10" |

| Row spacing | in | 5" / 6.5" |

| Number of drill openers | pcs | 48 / 36 |

| Drill opener down pressure | lb | 132 |

| Number of rotors | pcs | 96 / 74 |

| PTO shaft RPM | RPM | 750 / 1000 |

| Rotor RPM | RPM | 346 / 462 |

| Distance between rotors | in | 9.65" |

| Blades size | in | 13"x0.5" |

| Max. working depth* | in | 10" |

| Frame type | folding | |

| Horsepower requirement* | hp | 280-430 |

| Max. total weight** | lb | 18,532 |

* depends on soil conditions **according to the machine equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.