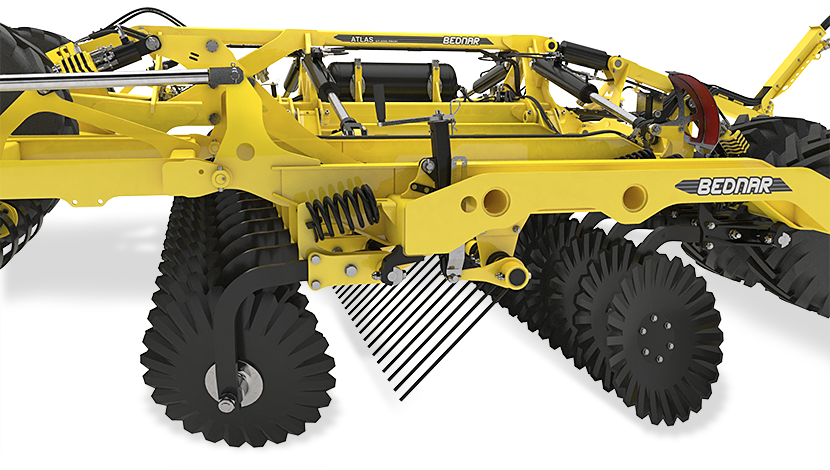

Topelt eesmised tugirattad

Järgivad täiuslikult maapinda ning hoiavad seatud töösügavust kogu masina laiuses.

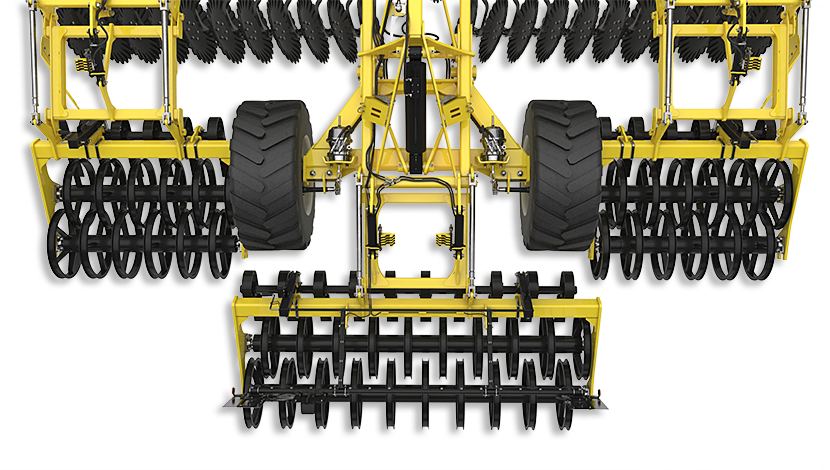

ATLAS AO_PROFI GEN II is designed for cutting, mixing and incorporating large quantities of crop residues and organic matter in the soil, even in wet conditions. The key advantage of the ATLAS AO_PROFI harrow is provided by the large disc diameter 650 mm, the robust design, high frame clearance, spacing of the individual working sections.

6-16 cm

5-7 m

250-450 k

The ATLAS AO_PROFI model line is a robust line of versatile compact disc harrow with properties suitable for processing large quantities of crop residue.

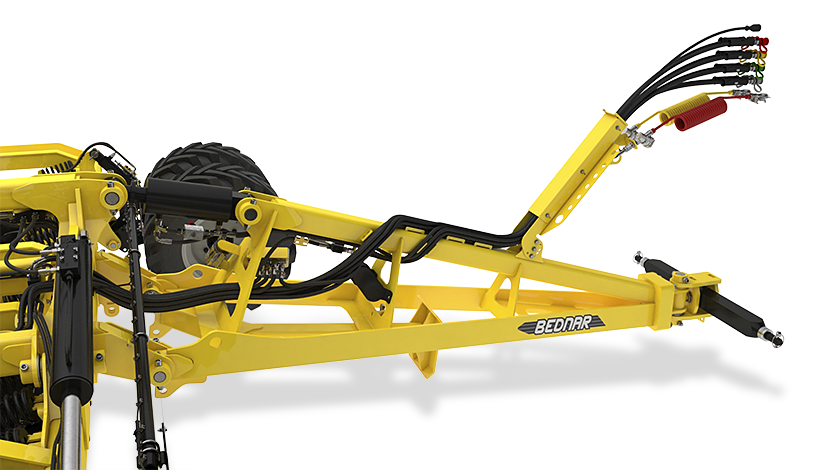

The ATLAS AO_PROFI GEN II compact disc harrow is equipped with a hydraulic drawbar. We use this type of technical design to provide the ideal the connection to the tractor, and more importantly, improve the quality of work because the compact disc harrow contours any terrain unevenness perfectly.

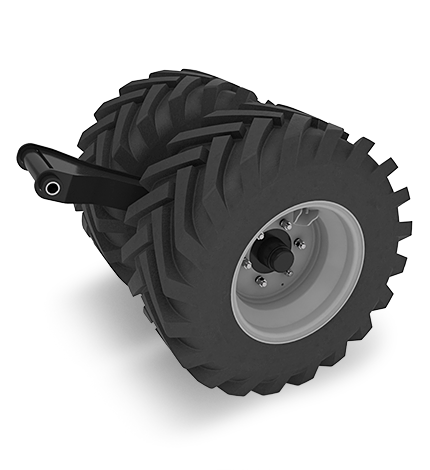

ATLAS AO_PROFI GEN II can be equipped with single or double support wheels. These guarantee excellent terrain following and maintaining of the set working depth throughout the entire working width of the machine.

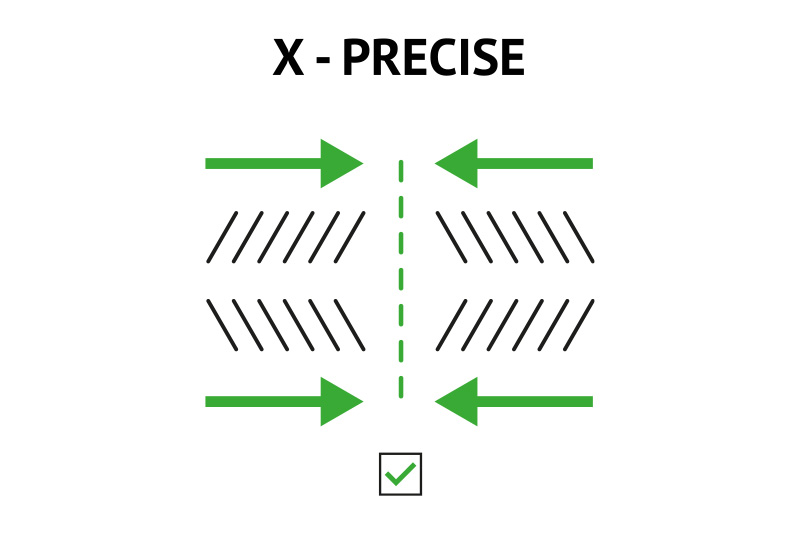

ATLAS AO_PROFI GEN II models have disc sections arranged in the pattern of X. This innovative technical design eliminates drifting of the machine to the side. That allows the compact disc harrow to precisely follow the tractor track. The central double disc reduces the risk of ridge formation.

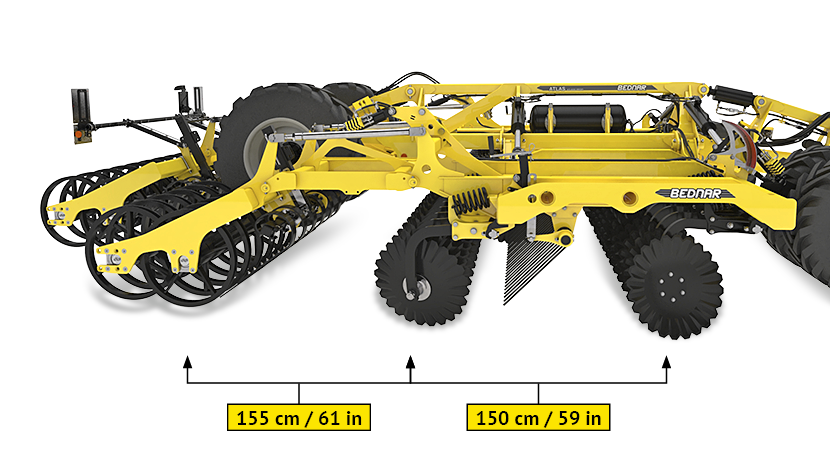

ATLAS AO_PROFI GEN II heavy-duty compact disc harrows have properties that predetermine the machine to be used for processing large quantities of crop residue, catch crop and other organic matter (slurry, manure). For trouble-free work and elimination of potential clogging of the machine, even when working in wet conditions, this model line offers optimum distance between the individual working sections. The distance between the front and rear row of the disc section is more than 150 centimetres and the distance of discs to the rear packer axis is up to 145 cm. The frame clearance is approximately 70 centimetres and it provides trouble-free throughput.

A tine deflector can be ordered between the disc sections. The deflector serves to direct the flow of material created by the front disc section. It prevents the second disc section from clogging. The deflector is very convenient and easy to adjust.

The two-row layout of rear packers provides better stability at high speed than one row design, and also eliminates any gap in the compact disc harrow with two rollers in one row. The integrated axle ensures even distribution of the machine weight and eliminates its swaying. Moreover, it ensures safer transport and reduces the turning radius of the tractor with the harrow at the headland.

ATLAS AO_PROFI GEN II can now be equipped with wide tyres 500/60-22.5. This tyre size eliminates tracks, for example when turning the machine on headlands in wet conditions. Wide tyres provide greater stability even at high transport speeds.

The ATLAS AO_PROFI GEN II disc harrow is equipped with easy working depth adjustment even in its basic version. The working depth is adjusted hydraulically using spacers on the hydraulic cylinders, which are part of the rear cylinder frames. The working depth is very clearly visible from the tractor cab on the working depth scale indicator.

For perfect soil levelling, the ATLAS AO_PROFI GEN II can be equipped with the Crushbar levelling bar mounted in front of the rear rollers. The rear rollers only consolidate the soil and do not level it. The result is perfectly level ground.

ATLAS AO_PROFI GEN II compact disc harrows are always equipped with a parallel linkage of rear rollers in the double packer configuration. This technical feature always guarantees contact of the second row of rollers with the soil ensuring high-quality consolidation.

Võtke meiega julgesti ühendust või leidke kohalik edasimüüja.

Meie kontaktid Leia edasimüüjaA concise summary of the main working parts of the disc cultivator.

A hydraulically adjustable drawbar contributes to perfect terrain contouring and levelling any unevenness.

Provides excellent terrain contouring and maintains the set working depth along the entire width of the machine.

Disc section with notched discs with a diameter of 650 x 6 mm or agressive discs with a diameter of 620 × 6 mm.

Each disc arm is protected against overload by a spring reset system. The release force of 270 kg.

A deflector can be placed between the disc sections, which ensures smooth discing without clogging in the case of larger amounts of material and higher working speeds.

Provides even distribution of the machine weight, contributes to better stability, and eliminates the risk of machine swaying at higher working speeds. Another advantage lies in the reduced turning radius at the headland and good manoeuvrability, even in rugged terrain.

The levelling board is used for levelling off any unevenness behind the disc section. The outcome is a perfectly levelled field.

The wide range of rear packers make it possible to adjust the machine to any conditions. Two-row packer layout prevents machine swaying during work. The packers help close the surface and prevent evaporation of soil moisture.

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own ATLAS AO_PROFI GEN II disc cultivator to precisely match your needs.