Easily accessible three-point hitch for connection of a seed drill combination to the rear three-point tractor hitch.

The KATARA KN_S mounted seed drill combination is designed for conventional farmers seeking a combination of high yields and farming efficiency by minimizing the number of working operations. KATARA KN_S brings the best of BEDNAR technical solutions. It is a combination of KATOR KN power harrow, recognised for their robustness and higher number of rotors per meter of working width, with a well-proven seed bar.

6 m

280-430 k

Mounted seed drill combination for establishing crops in tilled soil.

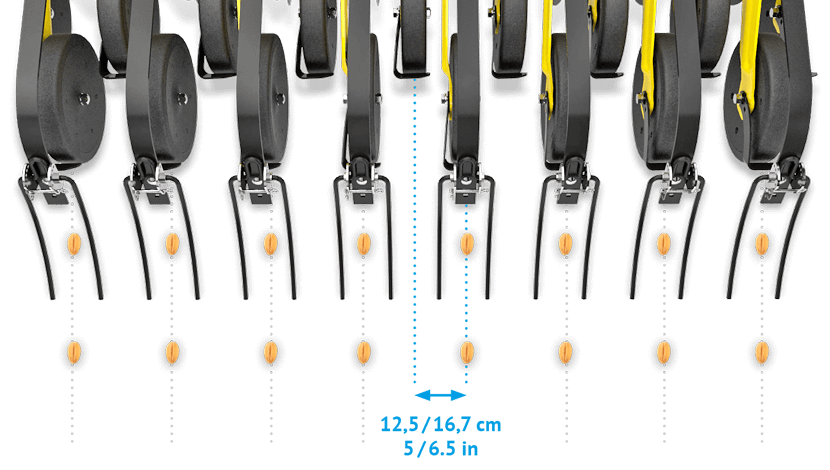

KATARA KN_S is designed for farmers using tillage technologies. The high number of rotors per meter of working width in combination with high circumferential speed guarantees quality preparation of the seedbed. The seed has superb contact with the soil and moisture for subsequent development. For this purpose, we have specially developed a seed bar with row spacing of 12.5 cm.

The seed drill combination is also suitable for establishing crops in min-till systems – e.g. deep soil tillage using a subsoilers or tine cultivators. Power harrow ensures the optimum seedbed preparation by crumbling clumps and cutting roots and plant residues. The seed bar with row spacing of 16.7 cm is perfect for high plant residue levels on the soil surface.

For maximum use of power harrow, the seed bar can simply be dismounted. Disconnection of the seed bar is fast, easy and requires no special tools. The KATOR KN power harrow can therefore be used separately, for example for preparing soil prior to planting potatoes or soil preparation for hard-to-work soils.

When soil preparation is needed between seeding passes, you don’t have to detach the seed bar. The KATARA KN_S drill combination allows the seed bar to be raised by 150 mm, enabling soil preparation only, without simultaneous seeding.

The KATARA KN_S seed drill combination in the transport position offers one of the smallest transport widths on the market – a mere 2.5 metres. KATARA KN_S fulfils all EU requirements for road travel. The seed bar is very close to the rear packer. This structural property is key for an optimum centre of gravity, which is very close to the rear tractor hitch.

The heart of the KATARA KN_S seed drill combination is its proven KATOR power harrow, which offer high number of rotors per meter of working width. The spacing of individual rotors is 24.5 cm. The high number of rotors ensures quality crumbling of soil, even in dry periods or during cultivation of heavy soils. Hydraulic adjustment of the working depth of the power harrow is a part of the basic machine equipment.

The KATARA KN_S seed drill combination is fitted as part of the standard equipment with seeding coulters with row spacing of 12.5 cm. This spacing of seeding coulters is suitable for systems with high representation of cereals in the crop rotation. The row spacing of 16.7 cm is suitable for establishing crops on hard soils or in minimum tillage systems.

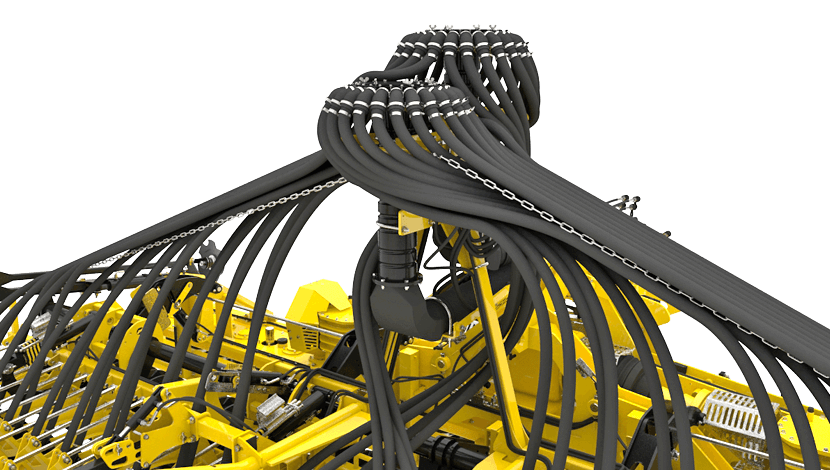

From the first designs, the KATARA KN_S machine was intended to feature a user-friendly system of seed bar disconnection. The distribution head is a part of the seed bar frame, so it requires no additional disassembly. Between the distribution head and power harrow frame is a bracket, attached to which are the distribution pipes, hydraulic hoses and cable harnesses. The seed bar is simply detached using the quick-release stops and safely placed on the parking leg. The entire disassembly process is quick and requires no tools.

As a part of the basic equipment, the KATARA KN_S seed drill combination features one distribution head. For maximum accuracy when seeding and saving seed costs, the seed drill combination can be fitted with a pair of distribution heads. In this case, the seed drill combination offers the option of switching off half of the machine working width.

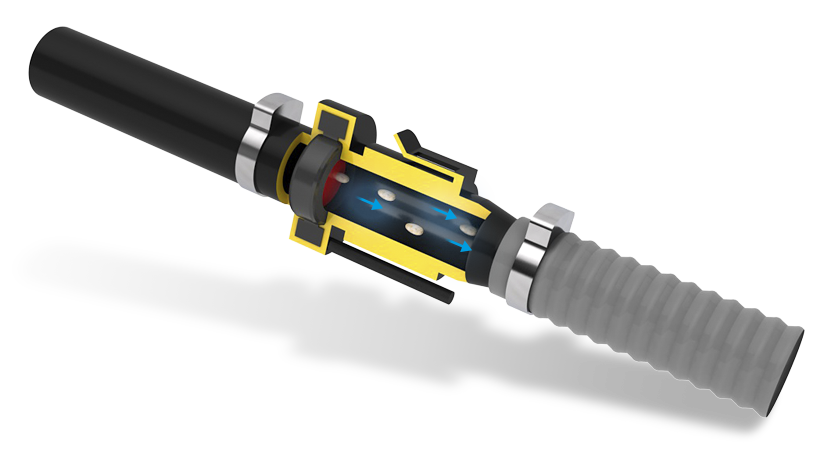

The seed drill combination can be equipped upon request with seed flow sensors that provide the operator information through the monitor in case of clogging of the seed hose. This element guarantees maximum seeding accuracy. The operator always has a perfectly clear overview of the fluid flow of individual seed hoses.

Connection of the seed drill combination with BEDNAR FERTI-BOX FB_F / FB_F Dual or SEED BOX SB front hoppers guarantees maximum compatibility and accuracy during seeding. BEDNAR has long used pressurised hopper design ensuring high dosing accuracy regardless of the seed or fertiliser size. It features easy seed rate adjustment or the option of variable dosing based on prescription maps.

Ease of use is a priority for today’s operators. The KATARA KN_S seed drill combination is equipped with the new BEDNAR EASY CONTROL software, which guarantees easy and clear operation. The software offers clear, easy and intuitive control of the seed drill.

The main working parts of a mounted seed drill combination concisely and clearly.

Easily accessible three-point hitch for connection of a seed drill combination to the rear three-point tractor hitch.

The robust gearbox for perfect power transmission ensures quality work of individual rotors of the power harrow.

Proven KATOR KN power harrow with a high number of rotors per meter of working width for quality crumbling and tillage.

The rear packer helps in the final crumbling of clumps and creates the seedbed structure.

The pair of distribution heads ensures fluid seed flow to the seeding coulters. This configuration enables switching off of half the seed bar working width for maximum precision and saving on seed.

The seed bar is formed of a proven solution of double-disc seeding coulters mounted via parallelogram for even placement into the soil in the entire machine working width. Optional row spacing of 12.5 or 16.7 cm.

It is useful for marking guide lines for smooth continuity of individual working widths in case the tractor is not equipped with GPS navigation.

The seeding coulter is mounted to the seed bar frame via parallel linkage. The system perfectly maintains the set working depth along the entire width of the machine.

| KATARA KN_S | KN 6000 S | |

|---|---|---|

| 工作宽度 | m | 6 |

| 运输宽度 | m | 2,5 |

| 运输长度 | m | 1,7 |

| 运输高度 | m | 3,6 |

| 犁刀间距 | cm | 12,5 / 16,7 |

| 犁刀数量 | ks | 48 / 36 |

| 犁刀下压力 | kg | 60 |

| 转子数量 | ks | 24 |

| PTO 轴转速 | ot/min | 750 / 1000 |

| 转子转速 | ot/min | 346 / 462 |

| 转子之间的距离 | cm | 24,5 |

| 刀片尺寸 | mm | 330x15 |

| Max. pracovní hloubka* | cm | 25 |

| 框架式 | 折叠式 | |

| Doporučený výkon* | hp | 280-430 |

| 最大限度。总重量** | kg | 8406 |

* depends on soil conditions **according to the machine equipment

At BEDNAR we work continuously to keep the information on this website accurate, up-to-date and useful. As we are dedicated to improving your experience and best farming performance, some specifications may be enhanced beyond what is currently shown. Complete technical specifications will be confirmed with your authorized BEDNAR representative at the time of ordering.