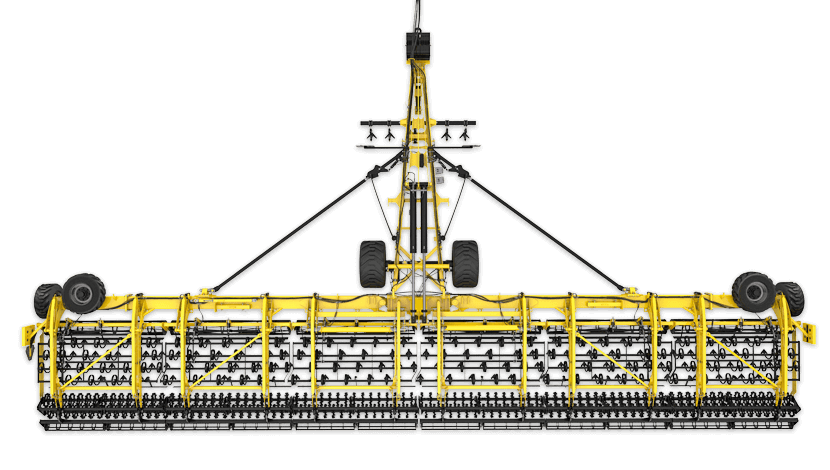

Telescopic track eradicators

A track eradicator with an adjustable width. It is used for loosening hardened tracks created by the tractor.

Since their market introduction, SWIFTER SM wide cultivators are the largest of the market, featuring a working width of 14 to 18 meters, ideal for powerful tractors. With increasingly short weather windows for soil cultivation, large farms are searching more outputs, to process more hectares on the same period. The widest SWIFTER SM cultivator efficiently handles over 230 hectares daily. Independent spring-loading of working sections ensures precise terrain contouring, even at such widths. Transport, folding, and unfolding are made easy and secure with the BAR-LOCK system.

2-12 cm

14-18 m

400-620 hp

A wide cultivator with a standard design suitable for traditional soil cultivation, as well as minimimum tillage systems.

Combining several operations into one means fewer passes through the field and lower costs of soil preparation. The front levelling bar perfectly levels any unevenness. The front slatted roller crumbles the clods. The main working section undercuts, aerates and warms up the soil layer. The final clod crumbling is provided by various types of rollers in combination with other equipment behind the rollers.

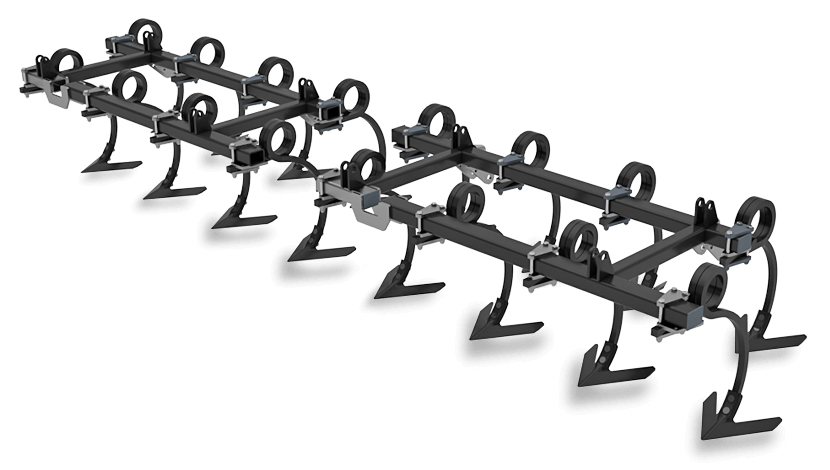

A sweep working section (summer and autumn soil cultivation – winter cereals, oilseed rape)

This working section can be used for summer and autumn preparation when soil needs to be loosened, undercut and mixed after the previous harvest. The 270 mm sweeps in two overlapping rows undercut the soil profile along the entire machine width, creating a firm bottom. At the same time, soil is aggressively processed thanks to the working angle of the sweeps, creating a loosening top layer. Each sweep is mounted on a flexible tine that provides a 3D effect (horizontal and vertical movement) which protects the sweep from damage.

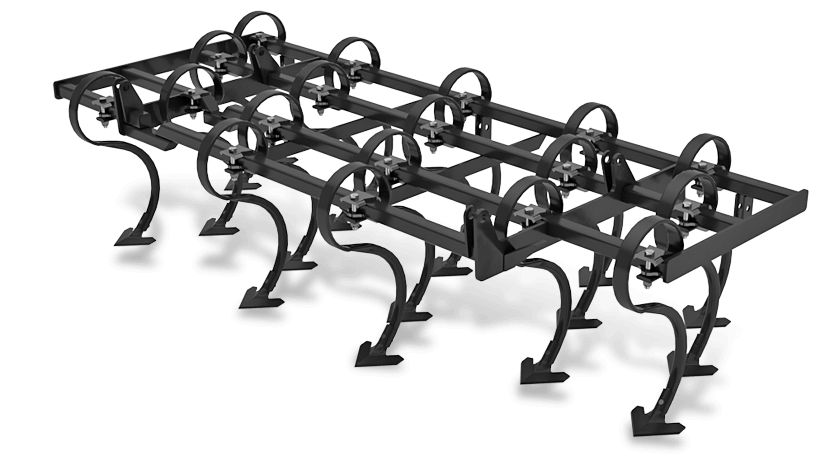

SB sweep section with spring sweeps (spring soil cultivation – sugar beet)

The section is especially suitable for spring cultivation before seeding sugar beet where it is required to adequately manage spring moisture, but still prepare a precise seedbed. The sweep angle does not mix soil vertically, but the soil is still undercut in the whole area thanks to the overlapping sweeps that are 170 mm wide. Another benefit is the reduced demand on the towing vehicle power.

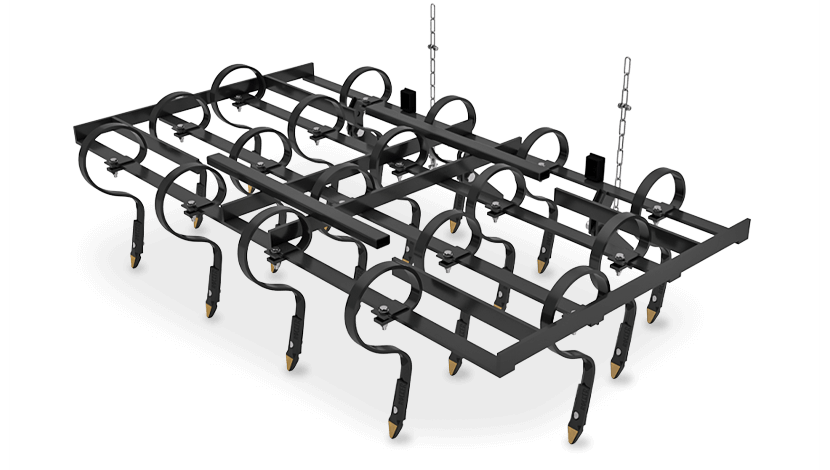

Gamma-point working section (spring soil cultivation – spring cereals, corn)

This section is suitable for early spring operations, such as required before seeding barley. The four rows of gamma points at a negative angle aerate and warm up soil without bringing wet particles to the surface, which preserves winter moisture. It is important for a fast start of the growth of spring crop. The spring-loading of each tine enables working at high speed. The gamma points for this section are also available in the LONG LIFE version.

The SWIFTER SM wide cultivator is designed for aggregation with the most powerful tractors on the market, such as quadtrac tractors. In combination with a working width of up to 18 metres, the high engine power, and the working speed, it is possible to achieve high daily outputs of up to 230 ha. Therefore, there is no need to deal with two-shift operation.

SWIFTER SM cultivators only have two side frame sections, unlike other competitive products in this category. The structural design of the machine reduces the number of hydraulic cylinders where side frame pressure could be lost. This design also reduces the number of points of lubrication, the overall wear of the machine, and it simplifies manipulation with the machine, both in the field and on the road.

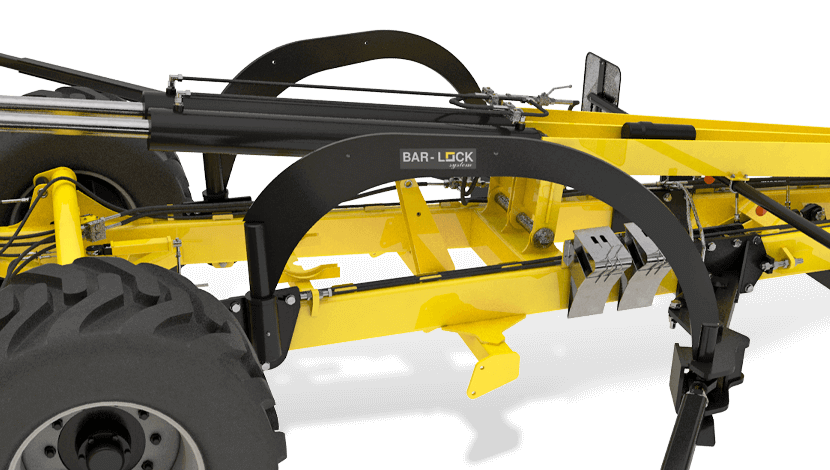

The design of the SWIFTER SM cultivator enables turning the machine at the headland without having to lift the working sections. Even so, we recommend turning on the headland with slightly excavated working sections and a larger turning radius. The fixed connecting rods of the BAR-LOCK system stabilise the side frames not only when turning, but also at higher working speed.

BAR-LOCK is a lock bar system. The system ensures a continuous, easy and safe unfolding of the machine from the transport to the working position, as well as machine reversing. Also, it secures the connecting rods of the side frames with the drawbar when in the working position. The entire operation is done from the comfort of the tractor cabin.

Do not hesitate to contact us or find the dealer for your area.

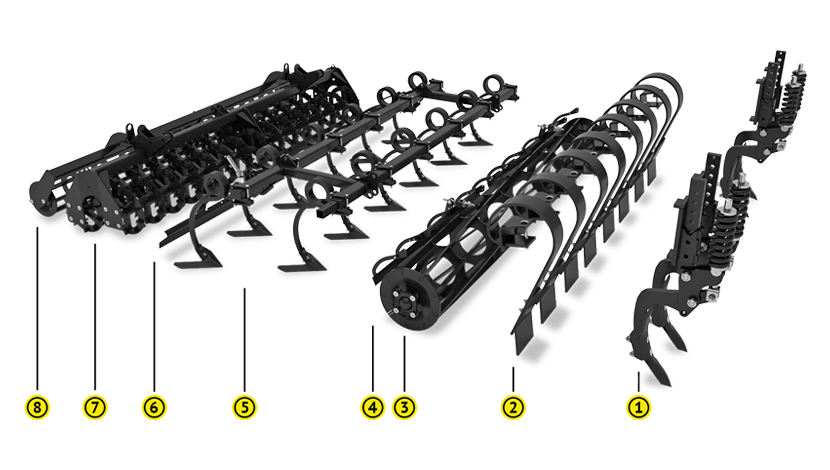

Contact us Find a dealerA concise summary of the main working parts of the seedbed cultivator.

A drawbar with the BAR-LOCK folding system for easy machine folding and unfolding during two minutes.

Used for loosening hardened tractor tracks.

Provides initial crumbling of larger soil particles and clods.

A selection of three different versions (2 rows of sweeps/ 4 rows of gamma points / 2 rows of SB sweeps) as needed for soil cultivation for the crop.

It levels off the soil surface after the sweep or gamma-point section.

The double-row crosskill rollers contribute to perfect crumbling of clods created by the sweep or gamma-point section.

The high circumferential speed of the finish roller provides intense crumbling.

Used for stabilising the side frames and provide perfect contouring of terrain unevenness.

“A perfectly prepared seedbed is our priority and I can confirm that the SWIFTER is the only machine that has always come through in our conditions. That is why our company already owns five wide cultivators. They are maximally used in the main season, and SWIFTER cultivators basically provide all the preparation, working literally 24 hours a day.”

Ing. Vítězslav Navrátil,

Chairman of the Board of Directors, ROSTĚNICE a.s., (district of Vyškov, CZ)

We know that everyone has different requirements for the optional machine equipment and its expected use. Therefore, you can specify your own SWIFTER SM wide seedbed cultivator to precisely match your needs.